描述

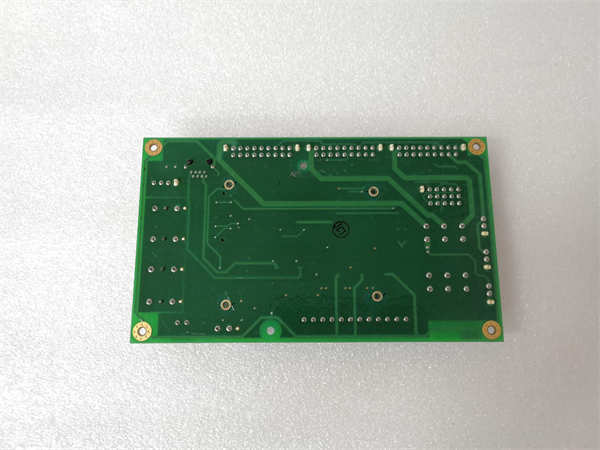

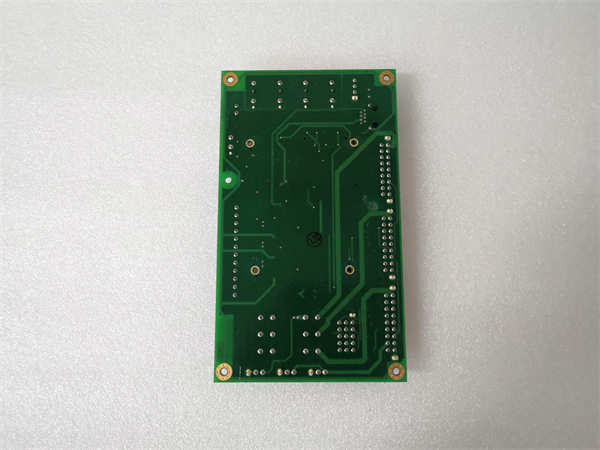

GE DS215KLDCG1AZZ03A是通用电气(GE)为工业自动化和控制系统设计的一款核心印刷电路板,主要用于涡轮机控制系统,尤其是Speedtronic Mark V系列。以下是其产品简介:

一、硬件组成与结构

物理特性

重量:约0.48千克(或1.07磅),尺寸适中,便于集成安装。

组件构成:包含多个关键元件,如:

集成电路:顶部有6个集成电路,下半部分有12个(含2个EPROM),负责数据处理与存储。

显示灯:中下半部分有32个白色显示灯,用于状态指示。

连接器:底部配备40针公连接器,支持外部设备通信。

其他元件:电阻网络、电容器、继电器、二极管等,确保信号传输与电源分配的可靠性。

防静电设计

由于集成大量敏感元件,操作时需佩戴防静电腕带,遵循严格的操作规范。

二、功能与应用

核心功能

输入输出控制:作为安全I/O模块,负责信号采集、处理与输出,支持电压、电流、热电阻等模拟量输入及电压、电流输出。

励磁系统控制:专用于同步发电机的励磁系统,实现电压调节与动态响应。

兼容性:支持与GE其他模块(如DS200系列)协同工作,适用于复杂控制系统。

应用领域

电力行业:涡轮机控制、发电机励磁系统。

石油化工:流程自动化、设备监控。

制造业:食品加工、制药、水处理等领域的自动化生产线。

三、技术特点

高可靠性

冗余设计:通过模块化架构与冗余通信接口,确保单点故障不影响系统运行。

环境适应性:宽温设计,支持工业现场复杂环境。

精密电路设计

信号传输:采用优质材料与精密布局,减少干扰,确保数据准确性。

能耗优化:集成低功耗组件,降低系统能耗。

认证与标准

通过德国莱茵公司IEC认证,符合工业通信协议(如Modbus、Profinet)。

DS200RT8AG3AHC

DS200RT8AG3AHC

GE DS215KLDCG1AZZ03A is a core printed circuit board designed by General Electric(GE)for industrial automation and control systems.It is mainly used in turbine control systems,especially the Speedtronic Mark V series.The following is a brief introduction to its product:

I.Hardware composition and structure

Physical characteristics

Weight:about 0.48 kg(or 1.07 pounds),moderate size,easy to integrate and install.

Component composition:Contains multiple key components,such as:

Integrated circuits:There are 6 integrated circuits on the top and 12 in the lower half(including 2 EPROMs),responsible for data processing and storage.

Display lights:There are 32 white display lights in the middle and lower half for status indication.

Connector:The bottom is equipped with a 40-pin male connector to support external device communication.

Other components:resistor networks,capacitors,relays,diodes,etc.,to ensure the reliability of signal transmission and power distribution.

Anti-static design

Due to the integration of a large number of sensitive components,it is necessary to wear an anti-static wrist strap during operation and follow strict operating specifications.

2.Functions and Applications

Core Functions

Input and output control:As a safe I/O module,it is responsible for signal acquisition,processing and output,and supports analog inputs such as voltage,current,and thermal resistance,as well as voltage and current output.

Excitation system control:Dedicated to the excitation system of synchronous generators to achieve voltage regulation and dynamic response.

Compatibility:Supports collaboration with other GE modules(such as the DS200 series)and is suitable for complex control systems.

Application areas

Power industry:turbine control,generator excitation system.

Petrochemical:process automation,equipment monitoring.

Manufacturing:automated production lines in food processing,pharmaceuticals,water treatment and other fields.

3.Technical features

High reliability

Redundant design:Through modular architecture and redundant communication interfaces,ensure that single point failures do not affect system operation.

Environmental adaptability:wide temperature design,supporting complex industrial site environments.

Precision circuit design

Signal transmission:Use high-quality materials and precise layout to reduce interference and ensure data accuracy.

Energy consumption optimization:Integrate low-power components to reduce system energy consumption.

Certification and Standards

It has passed the IEC certification of German Rhine Company and complies with industrial communication protocols(such as Modbus and Profinet).