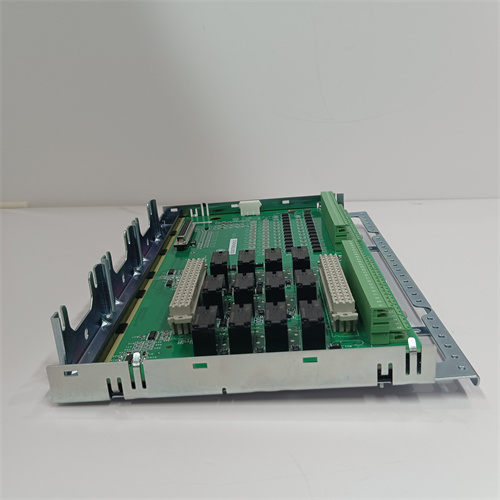

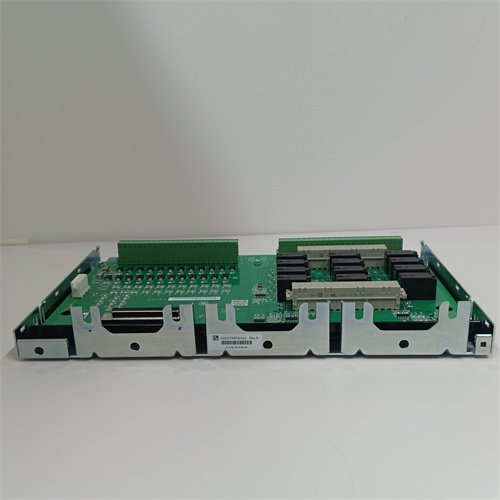

描述

产品概述

GE HWA143-TDM-PMC-V20是通用电气(GE)推出的工业以太网通讯模块,专为工业自动化系统设计,支持跨品牌PLC(可编程逻辑控制器)的高效数据交换与通信集成。其核心功能包括协议兼容性、远程管理及高可靠性,适用于DCS(分布式控制系统)迁移、PLC互联及工业物联网(IIoT)场景。

技术参数

硬件配置

通信协议:支持TCP/IP、UDP、Modbus TCP、以太网/IP(EtherNet/IP)及S5兼容协议。

处理器:内置高性能Productivity2000 CPU,配备50MB内存,支持快速扫描与多任务处理。

I/O扩展:

本地I/O点:400个(分立、模拟及专用模块兼容)。

远程扩展:总扩展能力达4,000个I/O点。

通信端口:5个通信接口,支持编程、扩展及客户端/服务器连接。

环境适应性

工业级抗干扰设计,适用于高温、高湿等恶劣环境。

支持宽温工作范围(未明确标注,但符合工业标准)。

核心功能特点

协议兼容性与互联性

支持多厂商PLC通信,包括罗克韦尔、西门子等品牌,实现开放统一的通信标准。

提供标准通信与S5兼容通信,适配传统及现代控制系统。

高效配置与管理

浏览器驱动安装工具:自动识别控制器标记或寄存器,减少配置错误,支持标签/寄存器的拖拽式数据交换。

远程监控与维护:通过Web界面实现远程访问、固件升级及诊断,降低维护成本。

数据安全性与稳定性

数据加密:保障传输数据的安全性。

冗余设计:支持热备冗余,确保系统持续运行。

灵活安装与扩展

可调节设计:适配不同厚度的工业外壳,兼容罗克韦尔LogixPAC控制器底盘。

模块化扩展:支持分立、模拟及专用I/O模块,满足复杂系统需求。

典型应用场景

工业自动化

实现PLC间数据交换与协调,优化生产线控制逻辑。

集成DCS系统,支持迁移过程中原有I/O硬件的保留与升级。

能源与建筑管理

监控电力系统、能源设备及建筑智能系统(如照明、空调)。

物联网与云计算

作为物联网网关,连接设备与云端平台,实现数据采集与远程管理。

Product Overview

GE HWA143-TDM-PMC-V20 is an industrial Ethernet communication module launched by General Electric(GE),designed for industrial automation systems and supports efficient data exchange and communication integration of cross-brand PLCs(programmable logic controllers).Its core functions include protocol compatibility,remote management and high reliability,and are suitable for DCS(distributed control system)migration,PLC interconnection and industrial Internet of Things(IIoT)scenarios.

Technical parameters

Hardware configuration

Communication protocol:Supports TCP/IP,UDP,Modbus TCP,Ethernet/IP(EtherNet/IP)and S5 compatible protocols.

Processor:Built-in high-performance Productivity2000 CPU,equipped with 50MB of memory,supports fast scanning and multitasking.

I/O extension:

Local I/O points:400(compatible with discrete,analog and dedicated modules).

Remote expansion:The total expansion capacity reaches 4,000 I/O points.

Communication port:5 communication interfaces,supporting programming,expansion and client/server connection.

Environmental adaptability

Industrial-grade anti-interference design,suitable for harsh environments such as high temperature and high humidity.

Supports wide temperature working range(not clearly marked,but complies with industrial standards).

Core functional features

Protocol compatibility and connectivity

Supports multi-manufacturer PLC communications,including brands such as Rockwell and Siemens,to achieve open and unified communication standards.

Provides standard communication compatible with S5 and is adapted to traditional and modern control systems.

Efficient configuration and management

Browser driver installation tool:Automatically identify controller tags or registers,reduce configuration errors,and support drag-and-drop data exchange of tags/registers.

Remote monitoring and maintenance:Remote access,firmware upgrade and diagnosis are achieved through the web interface,reducing maintenance costs.

Data security and stability

Data encryption:Ensure the security of transmitted data.

Redundant design:supports hot standby redundancy to ensure the continuous operation of the system.

Flexible installation and extension

Adjustable design:adapted to industrial shells of different thicknesses,compatible with Rockwell LogixPAC controller chassis.

Modular expansion:supports discrete,simulated and dedicated I/O modules to meet the needs of complex systems.

Typical application scenarios

Industrial automation

Realize data exchange and coordination between PLCs and optimize production line control logic.

Integrated DCS system to support the retention and upgrading of original I/O hardware during the migration process.

Energy and Building Management

Monitor power systems,energy equipment and building intelligent systems(such as lighting,air conditioning).

Internet of Things and Cloud Computing

As an Internet of Things gateway,it connects devices to cloud platforms to realize data collection and remote management.