描述

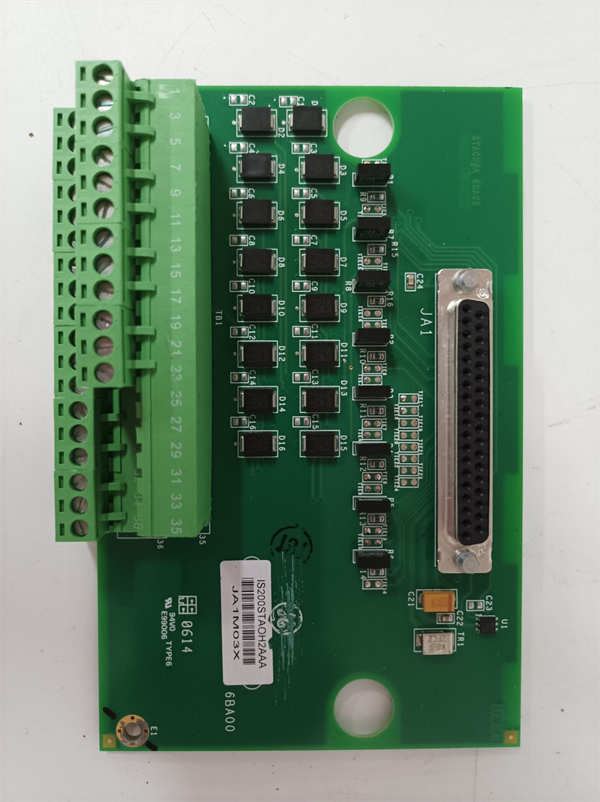

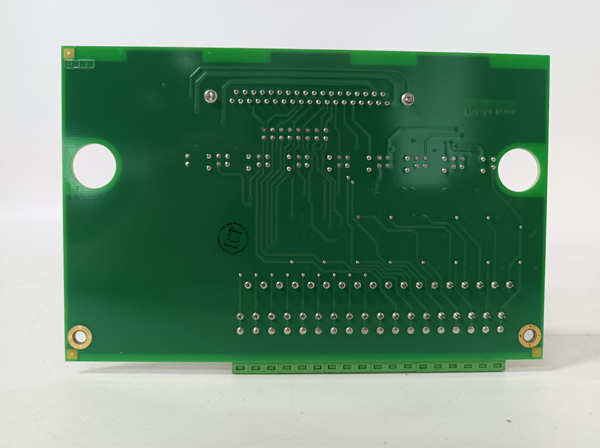

GE IC600CB527M是一款高性能工业自动化控制模块,主要用于连接PLC与现场设备,实现信号传输与控制功能。以下是其核心功能与技术参数的综合解析:

一、核心功能与性能

多种输入/输出类型

支持数字量、模拟量、开关量等多种信号类型,可灵活适配不同工业场景需求。

强大的处理能力

快速响应输入信号,准确输出控制指令,适用于高动态响应的工业控制系统。

支持16位分辨率模拟量输出,精度±0.1%FS,确保控制精度。

灵活的配置选项

支持模块扩展与定制化配置,可通过VMEbus接口与其他设备通信,兼容Modbus TCP/IP网络协议。

可靠性与稳定性

采用高品质电子元器件与严格生产工艺,确保长期稳定运行。

工作温度范围广,适应复杂工业环境。

二、技术参数

物理尺寸:130×80×25 mm(长×宽×高)

通道数量:4路模拟量输出

通信接口:VMEbus、Modbus TCP/IP

工作电压:支持工业标准电压范围

三、应用领域

工业自动化

电力、石油、化工、水处理等领域的数据采集与控制。

电梯、停车场、汽车制造等场景的设备联控。

智能制造

机器人运动控制、生产线实时监控。

能源管理

发电机励磁调节、风电场参数优化。

IC693CPU363

IC693CPU363

GE IC600CB527M is a high-performance industrial automation control module,mainly used to connect PLC and field equipment to realize signal transmission and control functions.The following is a comprehensive analysis of its core functions and technical parameters:

1.Core functions and performance

Multiple input/output types

Supports multiple signal types such as digital,analog,and switch,which can flexibly adapt to the needs of different industrial scenarios.

Powerful processing capabilities

Quickly respond to input signals and accurately output control instructions,suitable for industrial control systems with high dynamic response.

Support 16-bit resolution analog output,accuracy±0.1%FS,to ensure control accuracy.

Flexible configuration options

Support module expansion and customized configuration,can communicate with other devices through the VMEbus interface,and is compatible with Modbus TCP/IP network protocol.

Reliability and stability

Adopt high-quality electronic components and strict production processes to ensure long-term stable operation.

Wide operating temperature range,adapt to complex industrial environments.

2.Technical parameters

Physical size:130×80×25 mm(length×width×height)

Number of channels:4 analog outputs

Communication interface:VMEbus,Modbus TCP/IP

Working voltage:Supports industrial standard voltage range

3.Application areas

Industrial automation

Data acquisition and control in the fields of power,petroleum,chemical industry,water treatment,etc.

Equipment joint control in scenes such as elevators,parking lots,and automobile manufacturing.

Intelligent manufacturing

Robot motion control,real-time monitoring of production lines.

Energy management

Generator excitation regulation,wind farm parameter optimization.