描述

1.产品定位与核心功能

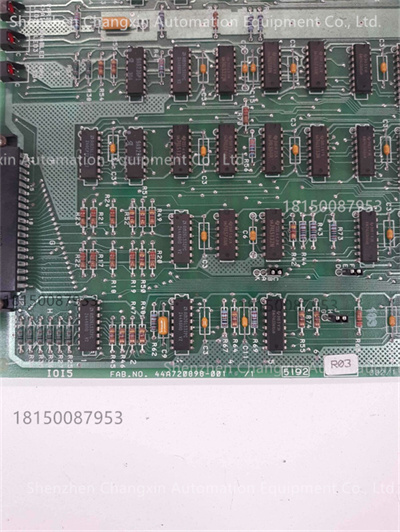

1.1产品类型

CPU控制器模块:

作为PACSystems RX3i控制系统的核心,负责执行用户程序、处理I/O数据、管理通信任务,并支持冗余配置以提高系统可靠性。

所属系列:

GE PACSystems RX3i系列,兼容RX3i系列I/O模块、通信模块及HMI/SCADA系统,适用于中大型工业自动化项目。

1.2核心应用场景

过程控制:

化工、石油天然气、制药等行业的连续生产过程控制(如反应釜温度、压力、流量控制)。

离散制造:

汽车制造、包装机械、电子装配等行业的顺序控制与运动控制。

能源管理:

发电厂、变电站的自动化监控与保护系统。

基础设施:

轨道交通、水处理、楼宇自动化等领域的集中控制。

2.关键技术参数

2.1处理器性能

CPU类型:

Intel Atom N270(1.6GHz,单核),或更高性能型号(需确认具体批次)。

内存配置:

用户程序内存:128MB(支持复杂逻辑与算法);

数据内存:64MB(用于存储过程变量、历史数据等);

非易失性存储:8MB(保留关键数据,断电不丢失)。

2.2运算能力

逻辑运算速度:

基本指令执行时间:0.01ms/千条(典型值),优于传统PLC(如0.1ms/千条)。

浮点运算能力:

支持32位浮点运算,适用于过程控制中的PID调节、数学运算等。

任务调度:

支持多任务并行处理(如实时控制任务、通信任务、HMI更新任务)。

2.3 I/O处理能力

本地I/O容量:

支持最多16个本地I/O模块(通过RX3i背板总线连接),覆盖数字量、模拟量、特殊功能模块(如高速计数、温度控制)。

远程I/O扩展:

通过EtherNet/IP、PROFINET、Modbus TCP等协议支持无限远程I/O站点(需配置通信模块)。

2.4冗余配置

热备冗余支持:

可与另一台IC600CB527M组成冗余系统,实现无缝切换(切换时间≤20ms),确保控制连续性。

冗余通信:

通过专用冗余链路(如光纤或双绞线)同步数据,避免单点故障。

3.通信与网络支持

3.1集成通信接口

以太网接口:

2个10/100Mbps RJ45端口,支持以下协议:

EtherNet/IP(工业以太网标准,兼容Rockwell设备);

Modbus TCP(通用设备互联);

PROFINET(需固件支持,适用于西门子生态);

SNMP(网络管理协议,便于远程监控)。

串行通信接口:

1个RS-232/RS-485端口,支持:

Modbus RTU(主/从模式);

ASCII/DF1协议(兼容旧设备)。

3.2高级通信功能

OPC UA Server:

内置OPC UA服务器,可直接与MES/ERP系统集成,无需额外网关。

安全通信:

支持TLS/SSL加密(防止数据窃听);

符合IEC 62443工业网络安全标准。

1.Product Positioning and Core Functions

1.1 Product Type

CPU Controller Module:

As the core of the PACSystems RX3i control system,it is responsible for executing user programs,processing I/O data,managing communications,and supporting redundant configurations to enhance system reliability.

Series:

GE PACSystems RX3i series.Compatible with RX3i series I/O modules,communication modules,and HMI/SCADA systems,it is suitable for medium-to large-scale industrial automation projects.

1.2 Core Application Scenarios

Process Control:

Continuous production process control(e.g.,reactor temperature,pressure,and flow control)in industries such as chemical,oil and gas,and pharmaceuticals.

Discrete Manufacturing:

Sequential control and motion control in industries such as automotive manufacturing,packaging machinery,and electronic assembly.

Energy Management:

Automated monitoring and protection systems for power plants and substations.

Infrastructure:

Centralized control in rail transit,water treatment,and building automation.2.Key Technical Parameters

2.1 Processor Performance

CPU Type:

Intel Atom N270(1.6GHz,single-core)or higher performance models(specific batches to be confirmed).

Memory Configuration:

User Program Memory:128MB(supports complex logic and algorithms);

Data Memory:64MB(for storing process variables,historical data,etc.);

Non-Volatile Memory:8MB(retains critical data and protects against power failures).

2.2 Computing Power

Logic Operation Speed:

Basic instruction execution time:0.01ms/1,000 instructions(typical),superior to traditional PLCs(e.g.,0.1ms/1,000 instructions).

Floating-Point Computing Capability:

Supports 32-bit floating-point operations,suitable for PID control and mathematical operations in process control.

Task Scheduling:

Supports multi-task parallel processing(such as real-time control tasks,communication tasks,and HMI update tasks).2.3 I/O Processing Capacity

Local I/O Capacity:

Supports up to 16 local I/O modules(connected via the RX3i backplane bus),covering digital,analog,and special function modules(such as high-speed counters and temperature control).

Remote I/O Expansion:

Supports unlimited remote I/O stations via protocols such as EtherNet/IP,PROFINET,and Modbus TCP(communications modules required).

2.4 Redundancy Configuration

Hot Standby Redundancy Support:

Can be combined with another IC600CB527M to form a redundant system,achieving seamless switchover(switchover time≤20ms)and ensuring control continuity.

Redundant Communication:

Data synchronization is achieved via dedicated redundant links(such as fiber optic or twisted pair cables),eliminating single points of failure.3.Communication and Network Support

3.1 Integrated Communication Interfaces

Ethernet Interface:

Two 10/100 Mbps RJ45 ports,supporting the following protocols:

EtherNet/IP(Industrial Ethernet standard,compatible with Rockwell devices);

Modbus TCP(universal device interconnect);

PROFINET(firmware support required,suitable for the Siemens ecosystem);

SNMP(network management protocol for remote monitoring).

Serial Communication Interface:

One RS-232/RS-485 port,supporting:

Modbus RTU(master/slave mode);

ASCII/DF1 protocol(compatible with legacy devices).

3.2 Advanced Communication Features

OPC UA Server:

A built-in OPC UA server enables direct integration with MES/ERP systems without the need for an additional gateway.

Secure Communication:

Supports TLS/SSL encryption(prevents data eavesdropping);

Compliant with the IEC 62443 industrial network security standard.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101