描述

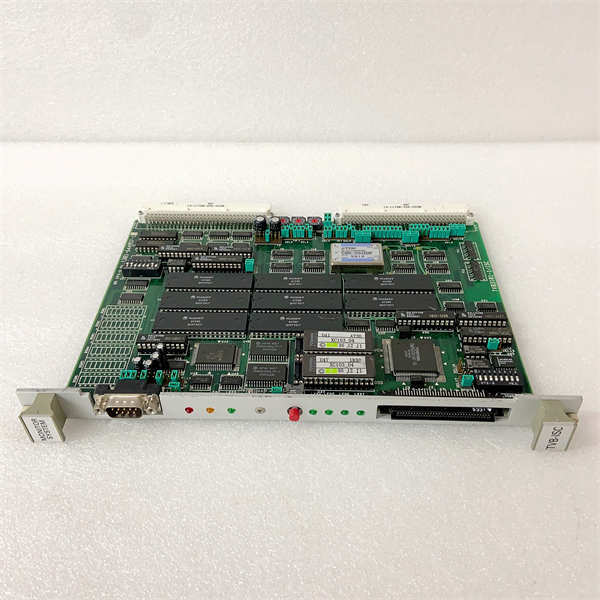

GE IC670CHS002是一款由通用电气(现为艾默生自动化)设计的工业级I/O接线端子模块,专为现场控制应用设计,广泛应用于工业自动化系统中。以下是其核心功能与技术特点的综合解析:

一、核心功能与结构

模块化安装平台

-作为2个附加I/O模块的安装底座,提供通信、电源及用户端子连接的统一平台,支持热插拔操作(即模块可带电安装或拆卸)。

兼容性与扩展性

-兼容多种GE Fanuc的I/O模块(如数字输入/输出、模拟量模块等),通过字母密钥系统确保每个插槽仅匹配指定模块类型,避免误插。

抗震与牢固设计

-采用盒式端子结构,最大端子扭矩可达4.5磅/英寸,防止工业环境中振动导致的松动,同时提供对齐槽以确保模块安装的精确性。

二、技术规格

电气参数

-工作电压:220V AC/DC

-输出频率:50kHz

-支持CANopen通信协议,兼容工业网络环境。

机械特性

三、应用场景

分散控制系统(DCS)

-作为DCS的I/O接口,实现传感器、执行器与控制核心的数据交互。

自动化生产线

-支持机器人、输送系统、包装机械等设备的运动控制与状态监测。

工业通信网络

-通过菊花链连接多个模块,构建分布式I/O网络,适用于复杂工业布局。

IC695CPE310-ABAB

IC695CPE310-ABAB

GE IC670CHS002 is an industrial-grade I/O terminal block designed by General Electric(now Emerson Automation).It is designed for field control applications and is widely used in industrial automation systems.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and structure

Modular installation platform

-As a mounting base for 2 additional I/O modules,it provides a unified platform for communication,power supply and user terminal connections,and supports hot-swap operations(that is,the module can be installed or removed with power on).

Compatibility and expandability

-Compatible with a variety of GE Fanuc I/O modules(such as digital input/output,analog modules,etc.),and the letter key system ensures that each slot only matches the specified module type to avoid mis-insertion.

Anti-vibration and firm design

-Adopting a box-type terminal structure,the maximum terminal torque can reach 4.5 pounds/inch to prevent loosening caused by vibration in industrial environments,and provide alignment slots to ensure the accuracy of module installation.

2.Technical Specifications

Electrical Parameters

-Working voltage:220V AC/DC

-Output frequency:50kHz

-Support CANopen communication protocol,compatible with industrial network environment.

Mechanical Characteristics

3.Application Scenarios

Distributed Control System(DCS)

-As the I/O interface of DCS,it realizes data interaction between sensors,actuators and control core.

Automated production line

-Supports motion control and status monitoring of equipment such as robots,conveying systems,and packaging machinery.

Industrial Communication Network

-Connect multiple modules through daisy chain to build a distributed I/O network,suitable for complex industrial layout.