描述

一、核心功能与定位

产品类型

功能:双轴运动控制器模块,专为工业自动化系统设计,支持数字舵机和带模拟指令输入的舵机控制,适用于高精度运动控制场景。

兼容性:与GE Fanuc 90-30系列PLC配合使用,支持自动数据传输(无需用户编程),并通过工厂电线和接线端子实现I/O连接。

核心特性

处理速度:块处理时间小于5毫秒,确保实时响应。

通信接口:支持串行端口(用于固件更新)和以太网复位功能,可切换端口配置或重置以太网固件。

安全机制:具备自诊断功能,模块故障时自动复位并重启。

二、技术参数

硬件配置

输入/输出:

数字输入:16点输入,8点一组共用公共端,支持漏型输入(24VDC)。

模拟输入:16通道,支持14种信号类型,可组合使用,双端差动输入。

隔离设计:每路通道独立电气隔离,抗强电干扰。

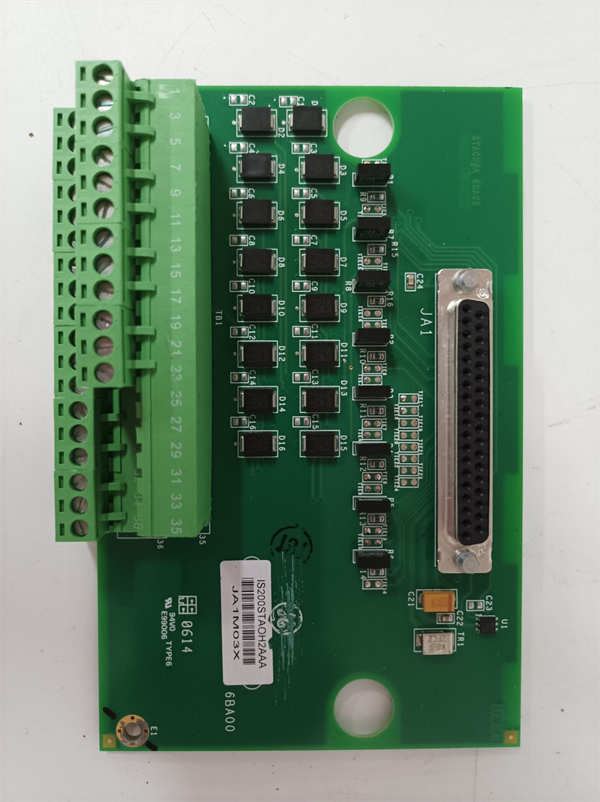

尺寸与重量:约120mm×80mm×40mm,重量0.5kg。

通信与协议

网络支持:集成RS-232、RS-485及以太网接口,支持DeviceNet终端和UCMM(非连接消息管理器)。

数据传输速率:最高支持500Kbps(DeviceNet网络)。

环境适应性

工作温度:-20°C至+70°C(具体需参考手册)。

防护等级:未明确标注,但符合工业级抗振动与电磁干扰标准。

三、典型应用场景

运动控制

数控机床:控制进给轴的高精度定位与加减速曲线。

机器人关节:实现多轴协同运动,支持复杂轨迹规划。

物料搬运系统:自动化生产线的精准定位与同步控制。

工业自动化

DCS系统集成:作为控制器模块,支持数据采集与逻辑控制。

过程控制:化工、冶金行业的温度、压力等参数调节。

电力与能源

发电机控制:励磁调节系统的信号处理与执行。

变电站自动化:安全联锁控制与实时监控。

IC693CPU363

IC693CPU363

1.Core functions and positioning

Product Type

Function:Dual-axis motion controller module,designed for industrial automation systems,supports digital servo and servo control with analog command input,suitable for high-precision motion control scenarios.

Compatibility:Used with GE Fanuc 90-30 series PLCs,supports automatic data transmission(no user programming required),and enables I/O connections via factory wires and terminals.

Core features

Processing speed:Block processing time is less than 5 milliseconds,ensuring real-time response.

Communication interface:Supports serial port(for firmware update)and Ethernet reset functions,switch port configuration or reset Ethernet firmware.

Safety mechanism:It has self-diagnosis function,and automatically resets and restarts when the module fails.

2.Technical parameters

Hardware configuration

Input/Output:

Digital input:16-point input,8-point common end,support leakage input(24VDC).

Analog input:16 channels,supports 14 signal types,can be used in combination,dual-ended differential input.

Isolation design:Each channel is independent electrically isolated and resists strong electrical interference.

Dimensions and weight:approximately 120mm×80mm×40mm,weight 0.5kg.

Communication and Protocol

Network support:Integrate RS-232,RS-485 and Ethernet interfaces,and supports DeviceNet terminals and UCMM(non-connected message manager).

Data transmission rate:up to 500Kbps(DeviceNet network).

Environmental adaptability

Operating temperature:-20°C to+70°C(refer to the manual for details).

Protection level:Not clearly marked,but it complies with industrial-grade vibration and electromagnetic interference standards.

3.Typical application scenarios

Motion control

CNC machine tools:controls the high-precision positioning and acceleration and deceleration curve of the feed shaft.

Robot joints:realize multi-axis collaborative motion and support complex trajectory planning.

Material handling system:Accurate positioning and synchronous control of automated production lines.

Industrial automation

DCS system integration:As a controller module,it supports data acquisition and logic control.

Process control:Adjustment of temperature,pressure and other parameters in the chemical industry.

Electricity and Energy

Generator control:signal processing and execution of excitation adjustment system.

Substation automation:safety interlocking control and real-time monitoring.