描述

GE IC698PSD300技术工控解析:高性能工业控制器与电源模块

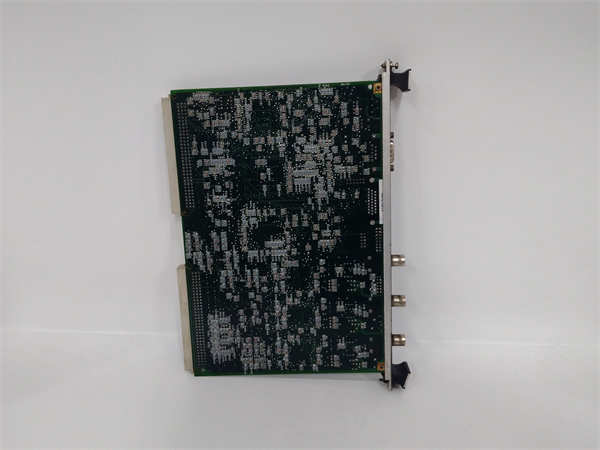

一、产品概述

GE IC698PSD300是通用电气(GE)推出的工业自动化核心模块,兼具控制器功能与电源管理能力,适用于机械制造、电力系统、自动化生产线等高可靠性场景。该模块支持分布式I/O扩展和多协议通信,是传统PLC向现代PAC(可编程自动化控制器)升级的重要组件。

二、技术参数与硬件配置

1.核心性能

电源类型:24 VDC,支持宽电压输入(18-30 VDC),输出功率高达300 W,适用于大功率设备驱动。

处理速度:0.72~16.3μs(不同型号差异),支持实时数据采集与逻辑控制。

通信接口:

以太网通讯(支持Modbus RTU、SNP协议)

RS-232/RS-485串口(用于编程与HMI通信)。

环境适应性:IP65防护等级,工作温度范围-30°C至70°C,湿度5%~95%(无凝露)。

2.存储与扩展

程序容量:45 KB(可扩展至2048 KB),支持梯形图、顺序功能图等编程语言。

I/O扩展:

最多支持8个I/O组,兼容GE VersaMax系列模块(如IC697CPU731、IC697MDL750)。

支持DIN导轨安装,兼容箱式、屏障式接线端子。

三、功能特点与优势

1.高可靠性设计

多重保护机制:

过压、过流、过热保护,自动触发停机并点亮红色LED指示灯。

气流传感器实时监测风扇状态,防止散热异常。

冗余能力:支持模块级冗余(如电源、通信模块),保障系统连续运行。

2.模块化与兼容性

灵活扩展:通过背板总线连接分布式I/O模块,支持现场总线(如DeviceNet、Profibus)与工业以太网。

传统系统迁移:兼容GE 90-30系列PLC模块,降低升级成本。

3.智能诊断与维护

状态指示:绿色LED(Output OK)表示正常运行,红色LED(Over Temp)提示过热或气流故障。

故障日志:内置诊断功能,可记录I/O异常、通信错误等事件,便于快速定位问题。

四、典型应用场景

机械制造:

驱动电机功率达750 W,适用于数控机床、包装机械的精准控制。

电力系统:

作为DCS(分布式控制系统)节点,监控发电厂机组运行状态。

自动化生产线:

集成逻辑顺序控制与PID调节,实现物流分拣、装配线同步等功能。

IC698CPE040

IC698CPE040

GE IC698PSD300 technical industrial control analysis:high-performance industrial controller and power module

1.Product Overview

GE IC698PSD300 is a core module of industrial automation launched by General Electric(GE),which has both controller functions and power management capabilities.It is suitable for high-reliability scenarios such as mechanical manufacturing,power systems,and automated production lines.This module supports distributed I/O extension and multi-protocol communication,and is an important component of the upgrade of traditional PLCs to modern PACs(programmable automation controllers).

2.Technical parameters and hardware configuration

1.Core Performance

Power supply type:24 VDC,supports wide voltage input(18-30 VDC),output power up to 300 W,suitable for high-power device drivers.

Processing speed:0.72~16.3μs(different models),supports real-time data acquisition and logic control.

Communication interface:

Ethernet communication(supports Modbus RTU and SNP protocols)

RS-232/RS-485 serial port(for programming and communication with HMI).

Environmental adaptability:IP65 protection level,working temperature range-30°C to 70°C,humidity 5%to 95%(no condensation).

2.Storage and Extension

Program capacity:45 KB(scalable to 2048 KB),supports programming languagessuch as ladder diagrams and sequential function diagrams.

I/O extension:

Supports up to 8 I/O groups and is compatible with GE VersaMax series modules(such as IC697CPU731,IC697MDL750).

Supports DIN rail installation and is compatible with box-type and barrier-type terminals.

3.Functional characteristics and advantages

1.High reliability design

Multiple protection mechanism:

Overvoltage,overcurrent,and overheating protection,automatically triggers shutdown and lights up the red LED indicator.

The airflow sensor monitors the fan status in real time to prevent abnormal heat dissipation.

Redundancy capability:supports module-level redundancy(such as power supply and communication modules)to ensure continuous operation of the system.

2.Modularity and compatibility

Flexible expansion:Connect distributed I/O modules through the backplane bus,supporting fieldbus(such as DeviceNet,Profibus)and industrial Ethernet.

Traditional system migration:compatible with GE 90-30 series PLC modules to reduce upgrade costs.

3.Intelligent diagnosis and maintenance

Status indicator:Green LED(Output OK)indicates normal operation,and red LED(Over Temp)indicates overheating or airflow failure.

Fault log:Built-in diagnostic function,can record I/O abnormalities,communication errors and other events,making it easy to quickly locate problems.

4.Typical application scenarios

Machinery manufacturing:

The power of the drive motor reaches 750 W,which is suitable for precise control of CNC machine tools and packaging machinery.

Power system:

As a DCS(Distributed Control System)node,it monitors the operating status of power plant units.

Automated production line:

Integrate logical sequence control and PID adjustment to realize functions such as logistics sorting,assembly line synchronization.