描述

产品概述

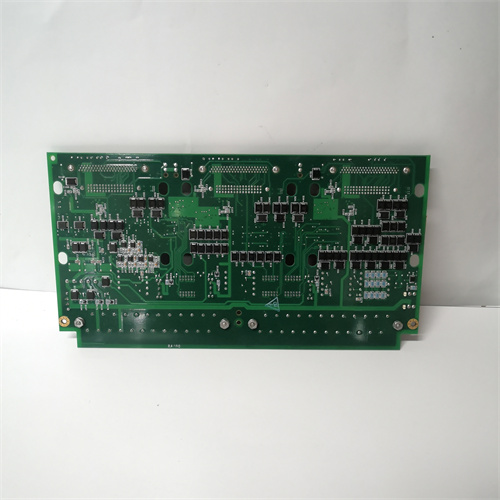

GE IS200JPDDG1AAA是一款直流配电板,属于通用电气(GE)Mark VI系统的核心组件,专为工业自动化和电力系统设计。该系统主要用于燃气/蒸汽轮机的监测、保护和控制,尽管Mark VI系列已过时,但其可靠性仍被广泛认可。该板通过将单一直流电源分配至多个负载,支持工业设备的稳定供电与信号传输。

技术参数

电气性能

输入电压:24V、48V或125V DC(可选)

输出电压:与输入电压一致(通常为24V DC)

最大输出电流:10A(具体因版本而异)

工作温度范围:-40°C至70°C

物理特性

尺寸与结构:矩形板,表面带有六个拨动开关、十二个保险丝、六个LED指示灯,以及七个2位插头(JD1-JD6及其他标签插头)。

传感器:集成一个标有“TB1”的传导传感器。

安装:支持导轨安装,板角钻孔便于固定。

通信与协议

支持Modbus TCP/IP等工业协议,实现多设备数据交互。

核心功能特点

电源分配与保护

将单一直流电源拆分为多个负载,支持工业设备的稳定供电。

内置过流、过压、欠压及频率偏差保护功能,确保系统安全。

模块化设计

作为Mark VI系统的分支电路板,可与其他模块(如继电器、传感器)集成,扩展系统功能。

支持热插拔维护,减少停机时间。

信号隔离与指示

通过拨动开关和保险丝实现负载控制与故障隔离。

LED指示灯实时显示电源状态,便于快速诊断。

高可靠性

采用高品质材料与制造工艺,适应恶劣工业环境(如高温、多尘)。

具备自诊断功能,可定位故障并触发报警。

典型应用场景

工业自动化

用于生产线控制、机器人操作及流程监测,支持信号采集与处理。

能源与电力

在燃气轮机、蒸汽轮机系统中实现电源分配与保护,保障设备安全运行。

制造业

应用于冶金、数控机械、食品厂等场景的设备供电与监控。

.Product Overview

GE IS200JPDDG1AAA is a DC distribution board,a core component of the General Electric(GE)Mark VI system,designed for industrial automation and power systems.This system is mainly used for monitoring,protection and control of gas/steam turbines,and its reliability is widely recognized despite the outdated Mark VI series.The board supports stable power supply and signal transmission of industrial equipment by distributing a single direct current power supply to multiple loads.

Technical parameters

Electrical performance

Input voltage:24V,48V or 125V DC(optional)

Output voltage:Consistent with input voltage(usually 24V DC)

Maximum output current:10A(specifically vary by version)

Operating temperature range:-40°C to 70°C

Physical characteristics

Dimensions and structure:Rectangular plate with six toggle switches,twelve fuses,six LED indicators,and seven 2-position plugs(JD1-JD6 and other label plugs).

Sensor:Integrate a conductive sensor marked”TB1″.

Installation:Supports rail installation,and the drilling of the plate angle is easy to fix.

Communication and Protocol

Supports industrial protocols such as Modbus TCP/IP to realize multi-device data interaction.

Core functional features

Power distribution and protection

Split a single DC power supply into multiple loads to support stable power supply of industrial equipment.

Built-in overcurrent,overvoltage,undervoltage and frequency deviation protection functions to ensure system safety.

Modular design

As a branch circuit board of the Mark VI system,it can be integrated with other modules(such as relays,sensors)to expand system functions.

Supports hot-swap maintenance to reduce downtime.

Signal isolation and indication

Load control and fault isolation is achieved through toggle switches and fuses.

LED indicators display power status in real time for quick diagnosis.

High reliability

It adopts high-quality materials and manufacturing processes to adapt to harsh industrial environments(such as high temperature and dust).

It has self-diagnosis function,can locate faults and trigger alarms.

Typical application scenarios

Industrial automation

Used for production line control,robot operation and process monitoring,and supports signal acquisition and processing.

Energy and Electricity

Power distribution and protection are realized in gas turbine and steam turbine systems to ensure the safe operation of equipment.

manufacturing

Equipment power supply and monitoring applied to metallurgy,CNC machinery,food factories and other scenarios.