描述

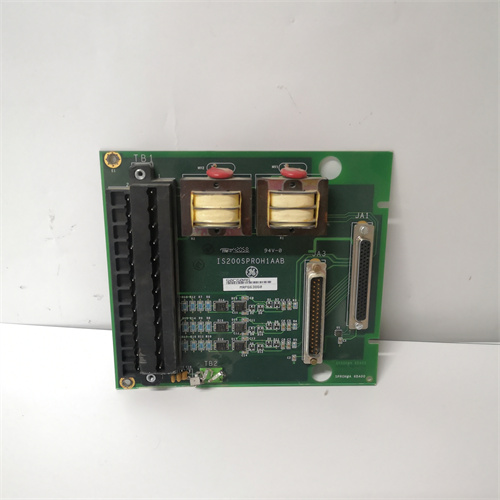

GE IS200SPROH1AAB MRP663860是通用电气(GE)生产的用于工业自动化控制的电路板模块,主要用于燃气轮机、蒸汽轮机等Mark VI系统,以下为详细介绍:

核心功能

信号处理与控制:作为数字信号处理器控制板,该模块负责处理和控制Mark VI系统中的各种信号,确保设备稳定运行。

多通道输入/输出:支持多通道模拟信号输入输出,可配置为-5至+5 VDC或-10至+10 VDC操作范围,并提供高分辨率(0.2 mV或0.4 mV)和跨度精度(0.05%)。

通信与集成:支持多种通信协议(如Modbus/TCP),可与其他系统组件进行数据传输和交互,便于集成到分布式控制系统(DCS)中。

远程监控与配置:内置Web浏览器、Telnet、SNMP等网络管理功能,支持远程监控和配置,提升运维效率。

技术参数

电气特性:

工作电压:24V DC或120V AC。

输出频率:72Hz。

分辨率:0.8µA(模拟输入通道),跨量程精度为0.05%(10µA)。

信号范围:每个通道可配置为-5至+5 VDC或-10至+10 VDC,分辨率分别为0.2 mV和0.4 mV。

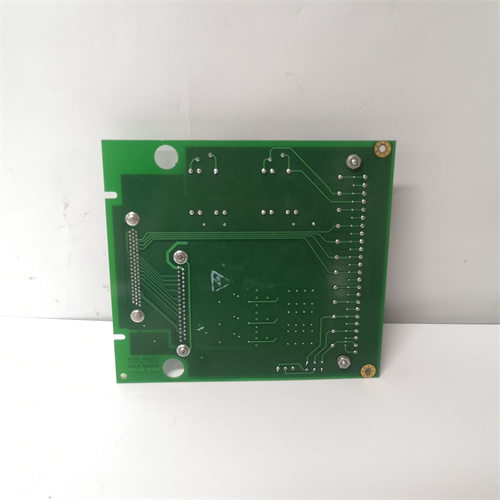

物理特性:

尺寸:约20×15×16 mm(具体尺寸可能因设计略有差异)。

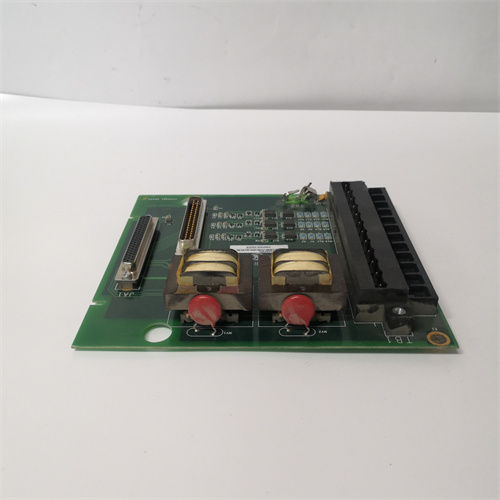

接口:包含12个端子(左边缘端子板)和2个黑色连接器端口(右侧银盘安装)。

变压器:顶部有两个方形红色变压器(标记为T1和T2),用于信号隔离和转换。

环境适应性:

工作温度:常温环境(具体范围未明确,但设计满足工业环境需求)。

防护等级:具备高可靠性和耐用性,适用于恶劣工业环境。

应用场景

燃气轮机控制:作为Mark VI系统的核心模块,用于燃气轮机的信号处理和控制。

蒸汽轮机监控:支持蒸汽轮机的状态监测和故障诊断。

工业自动化系统:集成到DCS中,实现数据共享、远程监控和控制功能。

能源与电力行业:广泛应用于电厂、钢厂、水泥厂等工业场景,提升设备运行效率和安全性。

GE IS200SPROH1AAB MRP663860 is a circuit board module for industrial automation control produced by General Electric(GE).It is mainly used in Mark VI systems such as gas turbines and steam turbines.The following is a detailed introduction:

Core functions

Signal processing and control:As a digital signal processor control board,this module is responsible for processing and controlling various signals in the Mark VI system to ensure stable operation of the equipment.

Multi-channel input/output:Supports multi-channel analog signal input and output,can be configured as-5 to+5 VDC or-10 to+10 VDC operating range,and provides high resolution(0.2 mV or 0.4 mV)and span accuracy(0.05%).

Communication and integration:Supports multiple communication protocols(such as Modbus/TCP),can transmit and interact with other system components,and is easy to integrate into the distributed control system(DCS).

Remote monitoring and configuration:Built-in network management functions such as Web browser,Telnet,SNMP,etc.,support remote monitoring and configuration,and improve operation and maintenance efficiency.

Technical parameters

Electrical characteristics:

Operating voltage:24V DC or 120V AC.

Output frequency:72Hz.

Resolution:0.8µA(analog input channel),cross-range accuracy is 0.05%(10µA).

Signal range:Each channel can be configured to-5 to+5 VDC or-10 to+10 VDC,with a resolution of 0.2 mV and 0.4 mV respectively.

Physical characteristics:

Dimensions:Approximately 20×15×16 mm(the specific dimensions may vary slightly due to design).

Interface:Contains 12 terminals(left edge terminal block)and 2 black connector ports(silver plate installation on the right).

Transformer:There are two square red transformers(marked T1 and T2)on the top for signal isolation and conversion.

Environmental adaptability:

Operating temperature:Normal temperature environment(the specific range is not clear,but the design meets the needs of industrial environment).

Protection level:With high reliability and durability,suitable for harsh industrial environments.

Application scenarios

Gas turbine control:As the core module of the Mark VI system,it is used for signal processing and control of gas turbines.

Steam turbine monitoring:Supports status monitoring and fault diagnosis of steam turbines.

Industrial automation system:Integrated into DCS to achieve data sharing,remote monitoring and control functions.

Energy and power industry:Widely used in industrial scenarios such as power plants,steel plants,cement plants,etc.to improve equipment operation efficiency and safety.