描述

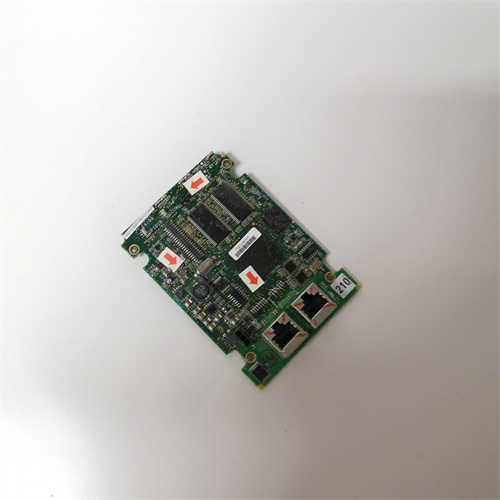

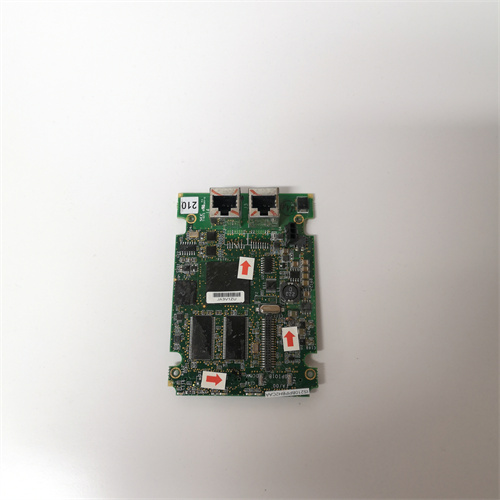

GE IS200SPROH1AAB(MRP663860)产品详情

一、产品概述

GE IS200SPROH1AAB(MRP663860)是通用电气(GE)公司为Speedtronic Mark VIe控制系统设计的一款处理器模块。Mark VIe系统广泛应用于燃气轮机、蒸汽轮机、发电机组等大型工业设备的控制与保护,确保设备在安全、高效的状态下运行。IS200SPROH1AAB模块作为系统的核心处理器,负责执行控制逻辑、数据处理、通信管理以及与系统中其他模块的协同工作。

二、产品特性

高性能处理器

强大运算能力:该模块搭载高性能的微处理器,具备快速的数据处理和运算能力,能够实时处理复杂的控制算法和大量的过程数据。例如,在燃气轮机控制中,需要实时计算燃料流量、空气流量、转速等多个参数,并根据预设的控制策略进行调整,IS200SPROH1AAB的高性能处理器可以确保这些计算和调整的及时性和准确性。

多任务处理:支持多任务并行处理,能够同时执行多个控制任务和数据处理任务,提高系统的整体效率和响应速度。例如,它可以同时处理控制指令的执行、故障诊断、数据记录等多个任务,确保系统的稳定运行。

丰富的通信接口

多种通信协议支持:具备多种通信接口,支持常见的工业通信协议,如Ethernet、Modbus、Profibus等。这使得它可以方便地与其他设备、系统进行数据交换和通信,实现工厂自动化系统的互联互通。例如,通过Ethernet接口,它可以与上位机监控系统进行通信,将设备的运行数据实时传输到监控中心,方便操作人员对设备进行远程监控和管理。

高速数据传输:通信接口具备高速数据传输能力,能够快速、准确地传输大量的数据。这对于实时性要求较高的工业控制系统非常重要,例如在紧急情况下,能够及时将故障信息传输到相关设备,以便采取相应的措施。

GE IS200SPROH1AAB(MRP663860)Product Details

I.Product Overview

GE IS200SPROH1AAB(MRP663860)is a processor module designed by General Electric(GE)for the Speedtronic Mark VIe control system.The Mark VIe system is widely used in the control and protection of large industrial equipment such as gas turbines,steam turbines,and generator sets to ensure that the equipment operates in a safe and efficient state.As the core processor of the system,the IS200SPROH1AAB module is responsible for executing control logic,data processing,communication management,and working in coordination with other modules in the system.

II.Product Features

High-performance processor

Powerful computing power:The module is equipped with a high-performance microprocessor with fast data processing and computing capabilities,and can process complex control algorithms and large amounts of process data in real time.For example,in gas turbine control,multiple parameters such as fuel flow,air flow,and speed need to be calculated in real time and adjusted according to the preset control strategy.The high-performance processor of the IS200SPROH1AAB can ensure the timeliness and accuracy of these calculations and adjustments.

Multitasking:It supports multitasking parallel processing and can execute multiple control tasks and data processing tasks at the same time,improving the overall efficiency and response speed of the system.For example,it can handle multiple tasks such as execution of control instructions,fault diagnosis,data recording,etc.at the same time to ensure the stable operation of the system.

Rich communication interface

Multiple communication protocol support:It has multiple communication interfaces and supports common industrial communication protocols such as Ethernet,Modbus,Profibus,etc.This makes it easy to exchange and communicate data with other devices and systems to achieve interconnection and interoperability of factory automation systems.For example,through the Ethernet interface,it can communicate with the host computer monitoring system and transmit the operating data of the equipment to the monitoring center in real time,which is convenient for operators to remotely monitor and manage the equipment.

High-speed data transmission:The communication interface has high-speed data transmission capability and can quickly and accurately transmit large amounts of data.This is very important for industrial control systems with high real-time requirements.For example,in an emergency,fault information can be transmitted to relevant equipment in a timely manner so that corresponding measures can be taken.