描述

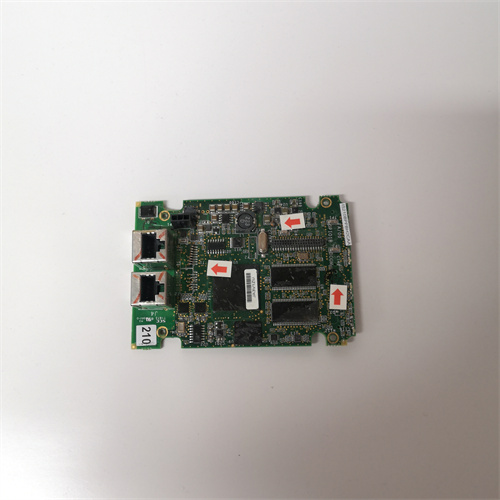

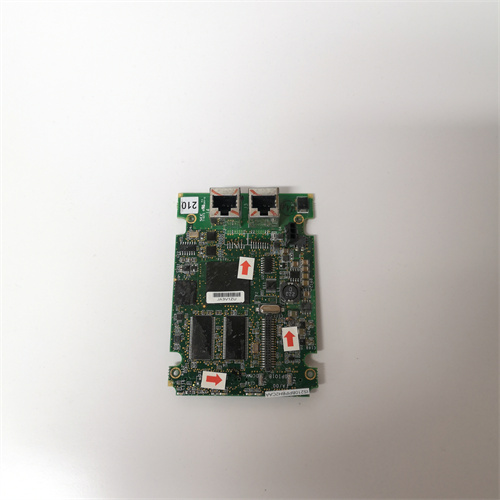

GE IS200TRLYH1BGF产品详情

一、基本信息

品牌:GE(通用电气,全球工业自动化与能源技术领导者,涵盖发电、电网、航空、医疗等领域)

型号:IS200TRLYH1BGF

类型:Mark VIe控制系统I/O模块,属于GE Speedtronic系列燃气轮机/蒸汽轮机控制系统的输入/输出组件,用于信号采集与驱动执行器。

用途:作为GE燃气轮机或联合循环机组(如9F、7F、6B等型号)的分布式I/O模块,连接现场传感器(如温度、压力、转速)和执行器(如阀门、电磁阀),实现数据采集与控制指令输出。

二、技术规格

1.模块功能

输入/输出类型:

热电偶/热电阻输入:支持J、K、T型热电偶或PT100/PT1000热电阻,用于温度测量(如排气温度、轴承温度)。

模拟量输入(AI):4~20 mA或0~5 V信号,采集压力、流量等过程变量。

模拟量输出(AO):4~20 mA信号,驱动阀门或变频器。

数字量输入(DI):24 VDC无源触点输入,监测开关状态(如阀门开/关到位)。

数字量输出(DO):24 VDC继电器输出,控制电磁阀或报警装置。

通道数:

具体配置需参考模块手册(如8路AI、4路AO、16路DI/DO等组合)。

2.电气参数

供电电压:

模块供电:24 VDC(±10%),功耗≤10 W。

现场侧供电:部分通道支持24 VDC或110 VDC独立供电(如继电器输出)。

信号隔离:

通道间电气隔离,耐压≥500 VAC,避免信号串扰。

响应时间:

模拟量输入更新时间≤10 ms,数字量输入≤5 ms。

3.环境与机械

工作温度:-20℃至+70℃(工业级宽温设计)。

防护等级:IP20(控制柜内安装),抗振动符合IEC 60068-2-6标准。

安装方式:DIN导轨或底板安装,支持热插拔(需系统配置允许)。

4.通信与接口

总线协议:

通过RIO(Remote I/O)总线与Mark VIe控制器(如IS200VPROH1A)通信,传输速率1 Mbps。

支持冗余RIO链路,提升可靠性。

诊断功能:

模块自检(如通道故障、电源异常)并通过总线上报至控制器。

LED指示灯显示模块状态(运行、故障、通信)。

三、产品优势

高可靠性

冗余设计:支持双RIO总线与双电源输入(需外部配置)。

抗干扰能力:符合EMC标准(IEC 61000-6),适应强电磁环境(如电厂、石化厂)。

灵活配置

通道混合:同一模块可集成AI、AO、DI、DO通道,减少硬件种类。

参数可编程:通过ToolboxST软件配置通道类型、量程、滤波时间等。

兼容性与扩展性

兼容Mark VIe全系列控制器(如IS200VPROH1A、IS200STCIH2ABB)。

支持扩展模块(如IS200ERIOH1A用于额外I/O容量)。

四、应用场景

燃气轮机控制

温度监测:连接排气热电偶,实时监控燃烧室与透平温度。

阀门控制:通过AO输出调节燃料阀开度,控制燃烧速率。

联合循环电厂

压力与流量测量:采集蒸汽压力、给水流量等信号,优化热效率。

联锁保护:通过DI/DO实现超速、超温等紧急停机逻辑。

GE IS200TRLYH1BGF Product Details

I.Basic Information

Brand:GE(General Electric,a global leader in industrial automation and energy technology,covering power generation,power grid,aviation,medical and other fields)

Model:IS200TRLYH1BGF

Type:Mark VIe control system I/O module,an input/output component of the GE Speedtronic series gas turbine/steam turbine control system,used for signal acquisition and actuator driving.

Use:As a distributed I/O module for GE gas turbines or combined cycle units(such as 9F,7F,6B,etc.),connect field sensors(such as temperature,pressure,speed)and actuators(such as valves,solenoid valves)to achieve data acquisition and control command output.

II.Technical Specifications

1.Module Function

Input/Output Type:

Thermocouple/Thermal Resistance Input:Supports J,K,T-type thermocouples or PT100/PT1000 thermal resistances for temperature measurement(such as exhaust temperature,bearing temperature).

Analog input(AI):4~20 mA or 0~5 V signal,collect process variables such as pressure and flow.

Analog output(AO):4~20 mA signal,drive valve or inverter.

Digital input(DI):24 VDC passive contact input,monitor switch status(such as valve open/close position).

Digital output(DO):24 VDC relay output,control solenoid valve or alarm device.

Number of channels:

For specific configuration,please refer to the module manual(such as 8-channel AI,4-channel AO,16-channel DI/DO,etc.).

2.Electrical parameters

Power supply voltage:

Module power supply:24 VDC(±10%),power consumption≤10 W.

Field side power supply:Some channels support 24 VDC or 110 VDC independent power supply(such as relay output).

Signal isolation:

Channels are electrically isolated,with a withstand voltage of≥500 VAC to avoid signal crosstalk.

Response time:

Analog input update time≤10 ms,digital input≤5 ms.

3.Environment and mechanics

Operating temperature:-20℃to+70℃(industrial wide temperature design).

Protection level:IP20(installed in the control cabinet),vibration resistance meets IEC 60068-2-6 standard.

Installation method:DIN rail or base plate installation,hot plug support(system configuration required).

4.Communication and interface

Bus protocol:

Communicate with Mark VIe controller(such as IS200VPROH1A)through RIO(Remote I/O)bus,with a transmission rate of 1 Mbps.

Supports redundant RIO links to improve reliability.

Diagnostic function:

Module self-check(such as channel failure,power supply abnormality)and report to the controller through the bus.

LED indicator shows module status(operation,failure,communication).

III.Product advantages

High reliability

Redundant design:supports dual RIO bus and dual power input(external configuration required).

Anti-interference ability:Complies with EMC standards(IEC 61000-6)and adapts to strong electromagnetic environments(such as power plants and petrochemical plants).

Flexible configuration

Channel mixing:The same module can integrate AI,AO,DI,and DO channels to reduce the number of hardware types.

Programmable parameters:Configure channel type,range,filter time,etc.through ToolboxST software.

Compatibility and scalability

Compatible with the full range of Mark VIe controllers(such as IS200VPROH1A,IS200STCIH2ABB).

Support expansion modules(such as IS200ERIOH1A for additional I/O capacity).

IV.Application scenarios

Gas turbine control

Temperature monitoring:Connect exhaust thermocouples to monitor combustion chamber and turbine temperatures in real time.

Valve control:Adjust the fuel valve opening through AO output to control the combustion rate.

Combined cycle power plant

Pressure and flow measurement:Collect signals such as steam pressure and feed water flow to optimize thermal efficiency.

Interlock protection:realize emergency shutdown logic such as overspeed and overtemperature through DI/DO.