描述

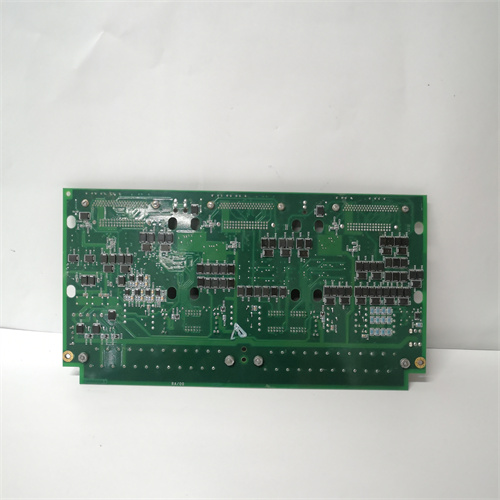

GE IS200TSVCH2ADC MRP061873是一款专为工业自动化设计的Mark VI端子板服务器,具有多通道输入、高精度测量、光学隔离、灵活通信和可靠保护等特点,以下为具体详情:

核心功能

多通道输入设计:提供八个模拟温度输入通道,可连接标准集成电路温度设备(ICTD),并支持扩展至128个模拟输入通道,适配从小型热成型到大型精炼、PID回路控制等多样化工业场景。

高精度测量能力:分辨率达0.017°C,精度±0.8°C,灵敏度1.0 mA/°C,确保温度监测的准确性和可靠性,满足工业过程对精密数据采集的需求。

光学隔离防护:通过模块与连接设备、共享I/O机架模块间的光学隔离技术,有效阻断电气干扰和故障传播路径,提升系统稳定性和安全性。

灵活通信支持:集成Modbus协议与RS485接口,支持远程通信和设备询问,同时提供以太网连接选项,便于与工业自动化系统无缝集成。

NAMUR标准兼容:内置符合NAMUR标准的继电器功能,可远程传输浓度警报级别、维护需求、服务状态及仪器故障信息,实现设备状态实时监控。

技术参数

电气特性:支持24V DC或120V AC供电,确保在复杂工业电源环境下的稳定运行。

环境适应性:通过模块化设计优化散热与防护性能,满足工业现场对设备耐用性的要求。

连接方式:采用顶部可插拔端子排的8针连接设计,简化现场设备接线流程,提升安装与维护效率。

保护功能:集成过流、过压保护机制,防止因异常工况导致的设备损坏,保障系统长期可靠运行。

应用场景

工业自动化控制:作为Mark VI系统的核心组件,用于实时监测与控制工业过程中的温度、压力等关键参数。

能源管理优化:在电力、石化等领域,通过高精度数据采集支持能源分配与设备效率优化。

智能制造升级:适配生产线自动化、设备监控等场景,通过远程通信功能实现集中管理与故障预警。

GE IS200TSVCH2ADC MRP061873 is a Mark VI terminal board server designed for industrial automation.It features multi-channel input,high-precision measurement,optical isolation,flexible communication and reliable protection.The following are the specific details:

Core functions

Multi-channel input design:Provides eight analog temperature input channels,can connect standard integrated circuit temperature devices(ICTDs),and supports expansion to 128 analog input channels,adapting to a variety of industrial scenarios from small hot forming to large refining,PID loop control,etc.

High-precision measurement capability:Resolution up to 0.017°C,accuracy±0.8°C,sensitivity 1.0 mA/°C,ensuring the accuracy and reliability of temperature monitoring,and meeting the needs of industrial processes for precision data acquisition.

Optical isolation protection:Through optical isolation technology between modules and connected devices and shared I/O rack modules,electrical interference and fault propagation paths are effectively blocked,improving system stability and safety.

Flexible communication support:Integrates Modbus protocol and RS485 interface,supports remote communication and device inquiry,and provides Ethernet connection options for seamless integration with industrial automation systems.

NAMUR standard compatibility:Built-in relay function that complies with NAMUR standards can remotely transmit concentration alarm levels,maintenance requirements,service status and instrument fault information to achieve real-time monitoring of equipment status.

Technical parameters

Electrical characteristics:Support 24V DC or 120V AC power supply to ensure stable operation in complex industrial power supply environments.

Environmental adaptability:Modular design optimizes heat dissipation and protection performance to meet the requirements of industrial sites for equipment durability.

Connection method:The 8-pin connection design with a pluggable terminal block on the top simplifies the on-site equipment wiring process and improves installation and maintenance efficiency.

Protection function:Integrated overcurrent and overvoltage protection mechanisms prevent equipment damage caused by abnormal working conditions and ensure long-term reliable operation of the system.

Application scenarios

Industrial automation control:As the core component of the Mark VI system,it is used to monitor and control key parameters such as temperature and pressure in industrial processes in real time.

Energy management optimization:In the fields of electricity,petrochemicals,etc.,high-precision data collection supports energy distribution and equipment efficiency optimization.

Intelligent manufacturing upgrade:Adapt to scenarios such as production line automation and equipment monitoring,and realize centralized management and fault warning through remote communication functions.