描述

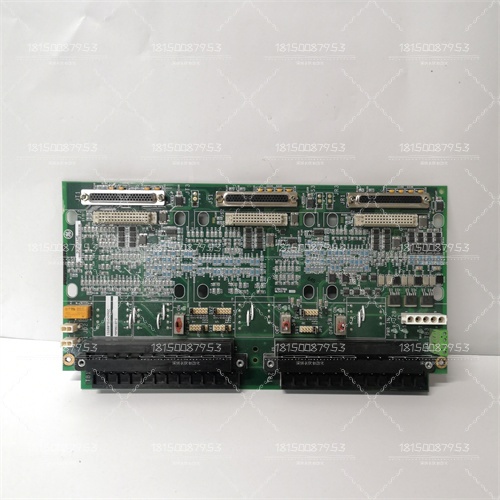

GE IS200TSVCH2ADC MRP061873产品详情

一、产品概述

GE IS200TSVCH2ADC是GE Energy(现属Baker Hughes)为Mark VI/VIe燃气轮机控制系统设计的一款高速振动监测模块,属于EX2000系列核心组件。该模块专用于实时采集、分析燃气轮机轴承及转子的振动信号,支持ISO 10816等国际振动标准,通过MRP061873标识(可能为模块序列号或批次代码)确保可追溯性。其高精度采样与频谱分析能力,可提前预警机械故障(如不平衡、不对中、松动、裂纹等),保障燃气轮机安全运行。

二、核心功能与技术规格

1.振动信号采集

通道配置:

4通道振动输入,支持加速度传感器(ACC)或速度传感器(VEL)连接(需选配适配电缆)。

每通道独立24位ADC(模数转换器),采样频率:最高51.2kHz(满足燃气轮机高频振动监测需求)。

输入范围:

加速度:±10g(可选±50g),频率响应:0.5Hz~10kHz。

速度:±100mm/s,频率响应:1Hz~1kHz。

抗干扰设计:

集成硬件低通滤波器(可配置截止频率),抑制高频噪声。

输入通道隔离电压:≥1500V AC,防止传感器故障影响模块运行。

2.实时分析与处理

频谱分析:

支持FFT(快速傅里叶变换),实时计算振动信号的频域特征(如1X、2X、3X倍频分量)。

可配置窗函数(Hanning、Flat Top等)优化频谱分辨率。

时域分析:

计算峰值(Peak)、峰峰值(Peak-Peak)、RMS值,监测振动幅值变化趋势。

支持波形触发记录,捕获瞬态振动事件(如启停机冲击)。

报警功能:

用户可设置三级报警阈值(Warning、Alarm、Danger),基于幅值、频率或包络线触发。

报警信息通过Mark VI/VIe控制器上传至HMI或SCADA系统,并记录时间戳。

3.数据存储与通信

本地存储:

内置非易失性存储器(NVM),可存储最近7天的振动趋势数据(采样间隔可调)。

支持事件触发存储(如报警发生时自动保存前后10秒数据)。

通信协议:

通过EX2000背板总线与Mark VI/VIe控制器通信,传输速率:1Mbps。

支持Modbus TCP/IP(需选配网关),便于与第三方系统集成。

三、硬件设计与环境适应性

1.机械结构

尺寸与安装:

符合EX2000标准机架尺寸(宽19英寸,高3U),支持前插拔设计,便于维护。

重量:约2.5kg,材质为铝合金,具备EMI/RFI屏蔽功能。

散热设计:

采用自然对流散热,无风扇设计,降低故障率。

工作温度范围:-20℃~+70℃(工业级),适应燃气轮机舱高温环境。

2.电源与冗余

供电要求:

输入电压:24V DC(±20%),由Mark VI/VIe电源模块统一供电。

功耗:≤15W(典型值),支持热插拔不影响系统运行。

冗余配置:

可与另一IS200TSVCH2ADC模块组成冗余对,主备模块自动切换时间<50ms。

四、典型应用场景

燃气轮机健康监测:

监测压缩机段、透平段轴承振动,诊断转子不平衡、叶片裂纹、齿轮磨损等故障。

结合Mark VI/VIe的转速信号,分析振动与负荷的关联性,优化运行策略。

联合循环机组(CCPP):

在燃气-蒸汽联合循环中,同步监测燃气轮机与汽轮机的振动,实现全厂机械状态一体化管理。

工业驱动系统:

扩展应用于大型压缩机、泵、风机等旋转设备,替代传统便携式振动分析仪,实现在线监测。

GE IS200TSVCH2ADC MRP061873 Product Details

I.Product Overview

GE IS200TSVCH2ADC is a high-speed vibration monitoring module designed by GE Energy(now Baker Hughes)for the Mark VI/VIe gas turbine control system.It is a core component of the EX2000 series.The module is dedicated to real-time acquisition and analysis of vibration signals of gas turbine bearings and rotors.It supports international vibration standards such as ISO 10816 and ensures traceability through the MRP061873 logo(which may be the module serial number or batch code).Its high-precision sampling and spectrum analysis capabilities can provide early warning of mechanical faults(such as imbalance,misalignment,looseness,cracks,etc.)to ensure the safe operation of gas turbines.

II.Core functions and technical specifications

1.Vibration signal acquisition

Channel configuration:

4-channel vibration input,supports acceleration sensor(ACC)or velocity sensor(VEL)connection(adapter cable required).

Each channel has an independent 24-bit ADC(analog-to-digital converter),sampling frequency:up to 51.2kHz(meeting the high-frequency vibration monitoring requirements of gas turbines).

Input range:

Acceleration:±10g(optional±50g),frequency response:0.5Hz~10kHz.

Speed:±100mm/s,frequency response:1Hz~1kHz.

Anti-interference design:

Integrated hardware low-pass filter(configurable cutoff frequency)to suppress high-frequency noise.

Input channel isolation voltage:≥1500V AC to prevent sensor failure from affecting module operation.

2.Real-time analysis and processing

Spectrum analysis:

Supports FFT(Fast Fourier Transform)to calculate the frequency domain characteristics of vibration signals in real time(such as 1X,2X,3X frequency components).

Configurable window function(Hanning,Flat Top,etc.)to optimize spectrum resolution.

Time domain analysis:

Calculate Peak,Peak-Peak,RMS values to monitor the trend of vibration amplitude changes.

Support waveform trigger recording to capture transient vibration events(such as start-up and shutdown shock).

Alarm function:

Users can set three levels of alarm thresholds(Warning,Alarm,Danger),based on amplitude,frequency or envelope trigger.

Alarm information is uploaded to the HMI or SCADA system through the Mark VI/VIe controller and the timestamp is recorded.

3.Data storage and communication

Local storage:

Built-in non-volatile memory(NVM)can store vibration trend data for the past 7 days(sampling interval is adjustable).

Support event-triggered storage(such as automatically saving the data before and after 10 seconds when an alarm occurs).

Communication protocol:

Communicate with the Mark VI/VIe controller through the EX2000 backplane bus,with a transmission rate of 1Mbps.

Support Modbus TCP/IP(gateway required)for easy integration with third-party systems.

3.Hardware design and environmental adaptability

1.Mechanical structure

Dimensions and installation:

Conforms to the standard rack size of EX2000(19 inches wide,3U high),supports front plug-in design,and is easy to maintain.

Weight:about 2.5kg,made of aluminum alloy,with EMI/RFI shielding function.

Heat dissipation design:

Adopts natural convection heat dissipation,fanless design,and reduces failure rate.

Operating temperature range:-20℃~+70℃(industrial grade),adapting to the high temperature environment of gas turbine cabin.

2.Power supply and redundancy

Power supply requirements:

Input voltage:24V DC(±20%),uniformly powered by Mark VI/VIe power module.

Power consumption:≤15W(typical value),supports hot plug-in without affecting system operation.

Redundant configuration:

Can form a redundant pair with another IS200TSVCH2ADC module,and the automatic switching time of the main and standby modules is<50ms.

4.Typical application scenarios

Gas turbine health monitoring:

Monitor the vibration of compressor and turbine bearings,and diagnose faults such as rotor imbalance,blade cracks,and gear wear.

Combined with the speed signal of Mark VI/VIe,analyze the correlation between vibration and load,and optimize the operation strategy.

Combined cycle unit(CCPP):

In the gas-steam combined cycle,synchronously monitor the vibration of gas turbines and steam turbines to achieve integrated management of the mechanical status of the entire plant.

Industrial drive system:

Extended application to large compressors,pumps,fans and other rotating equipment,replacing traditional portable vibration analyzers to achieve online monitoring.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101