描述

产品概述

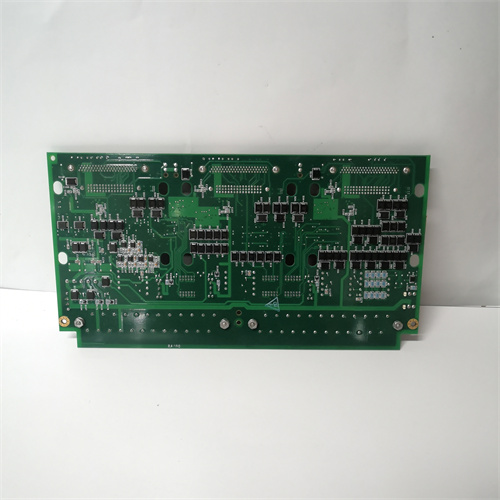

GE IS200VTCCH1CBB是通用电气(GE)Mark VI控制系统中的热电偶输入端子板,专为工业自动化和燃气/蒸汽轮机控制设计。其核心功能包括热电偶信号采集、转换及故障诊断,支持高精度温度测量和冗余控制,适用于发电、化工、制造业等严苛工业环境。

技术参数

输入能力

热电偶类型:支持E、J、K、S、T型热电偶及mV输入(-8 mV至+45 mV)。

通道数量:最多支持24个热电偶输入通道。

信号距离:热电偶可远至984英尺(约300米)距离控制柜。

硬件配置

端子板兼容性:支持DTTC(DIN欧式)和TBTC(配套)端子板,分为单工控制(TBTCH1C)和三重冗余(TMR,TBTCH1B)两种模式。

集成电路:包含Xilinx Spartan XCS30 FPGA、双端口SRAM、DSP TMS320C32PCMA50及CMOS静态RAM。

连接方式:前面板通过螺钉连接至PCB,配备三个LED指示灯(运行/故障/状态)。

环境适应性

工作温度:0°C至60°C。

防护设计:高频噪声抑制装置、冷端补偿,支持接地或非接地热电偶输入。

核心功能特点

信号处理与转换

将模拟热电偶信号转换为数字信号,供Mark VI系统分析处理。

支持动态信号通道,实现振幅与相位同步监测。

故障诊断与保护

检测热电偶信号异常(如断线、超限),自动隔离故障输入并触发报警。

内置冗余设计,确保系统在单点故障下仍正常运行。

通信与集成

通过IONet总线与Mark VI系统其他模块通信,支持以太网、串行接口(如RS-232/485)及Modbus协议。

兼容燃气轮机控制柜,适用于发电厂、化工厂等大型工业系统。

扩展性与兼容性

可与Mark VI系统的VTCC控制模块(单工或TMR模式)协同工作。

支持模块化安装,适配GE的IS200系列PLC和燃机控制系统。

应用场景

燃气/蒸汽轮机控制

监测涡轮机关键部件(如轴承、燃烧室)的温度,保障设备安全运行。

工业过程控制

用于化工、电力、船舶等行业的温度数据采集与实时监控。

预测性维护

通过长期温度趋势分析,预防设备过热或老化故障。

Product Overview

GE IS200VTCCH1CBB is a thermocouple input terminal board in GE’s Mark VI control system designed for industrial automation and gas/steam turbine control.Its core functions include thermocouple signal acquisition,conversion and fault diagnosis,support high-precision temperature measurement and redundant control,and are suitable for harsh industrial environments such as power generation,chemical industry,and manufacturing.

Technical parameters

Input capability

Thermocouple type:Supports E,J,K,S,T thermocouples and mV inputs(-8 mV to+45 mV).

Number of channels:Up to 24 thermocouple input channels are supported.

Signal distance:Thermocouple can reach 984 feet(approximately 300 meters)from the control cabinet.

Hardware configuration

Terminal board compatibility:supports DTTC(DIN European)and TBTC(matched)terminal boards,divided into two modes:simplex control(TBTCH1C)and triple redundancy(TMR,TBTCH1B).

Integrated circuit:Includes Xilinx Spartan XCS30 FPGA,dual-port SRAM,DSP TMS320C32PCMA50 and CMOS static RAM.

Connection method:The front panel is screwed to the PCB and is equipped with three LED indicators(run/fault/status).

Environmental adaptability

Operating temperature:0°C to 60°C.

Protection design:high-frequency noise suppression device,cold-end compensation,supporting grounded or non-grounded thermocouple input.

Core functional features

Signal processing and conversion

Converts the analog thermocouple signal into a digital signal for analysis and processing by Mark VI system.

Supports dynamic signal channels to realize synchronous monitoring of amplitude and phase.

Troubleshooting and protection

Detect abnormal thermocouple signal(such as disconnection,exceeding limit),automatically isolate the fault input and trigger an alarm.

Built-in redundant design ensures that the system still operates normally under a single point of failure.

Communication and integration

Communication with other modules of the Mark VI system through the IONet bus,supporting Ethernet,serial interfaces(such as RS-232/485)and Modbus protocol.

Compatible with gas turbine control cabinets,suitable for large industrial systems such as power plants and chemical plants.

Extensibility and compatibility

Works in conjunction with the VTCC control module(simplified or TMR mode)of the Mark VI system.

Supports modular installation,adapted to GE’s IS200 series PLC and gas engine control system.

Application scenarios

Gas/steam turbine control

Monitor the temperature of key components of the turbine(such as bearings and combustion chambers)to ensure the safe operation of the equipment.

Industrial process control

Used for temperature data acquisition and real-time monitoring in chemical,electricity,ships and other industries.

Predictive maintenance

Prevent equipment overheating or aging failure through long-term temperature trend analysis.