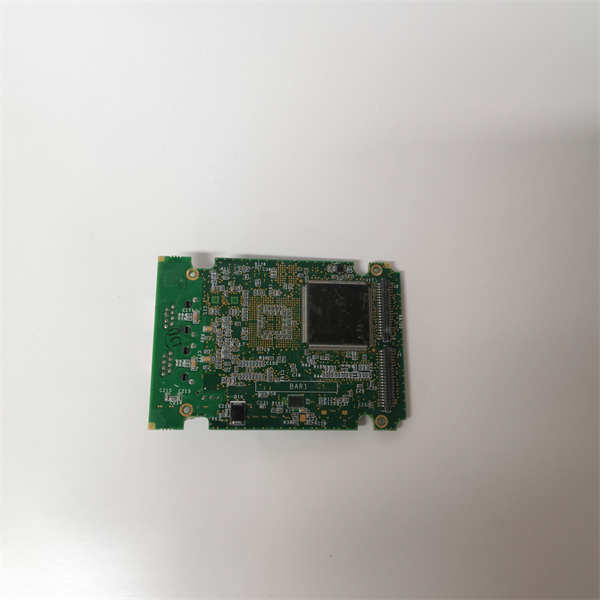

描述

GE IS210BPPBH2CAA是通用电气(GE)Mark VI系列控制系统中的核心模块,主要用于工业自动化和过程控制领域,以下是其产品详情:

核心功能

控制与数据处理

作为Mark VI系统的核心控制单元,模块承担系统控制逻辑执行、数据处理及通信任务,确保设备运行精确稳定。支持实时数据处理和复杂控制算法,可高效处理输入/输出信号,实现设备与传感器数据交互。

紧急保护与冗余支持

具备紧急保护功能,可快速切断电源或执行安全操作,防止设备损坏和生产损失。支持冗余配置,在单模块故障时仍能维持系统稳定运行,确保工业生产连续性。

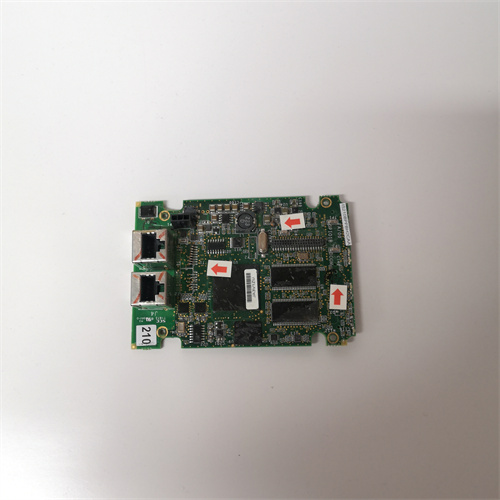

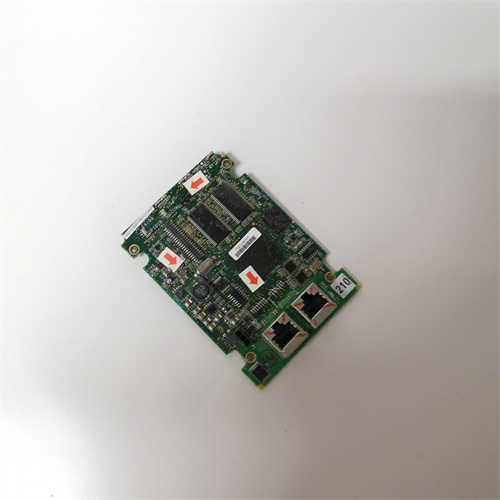

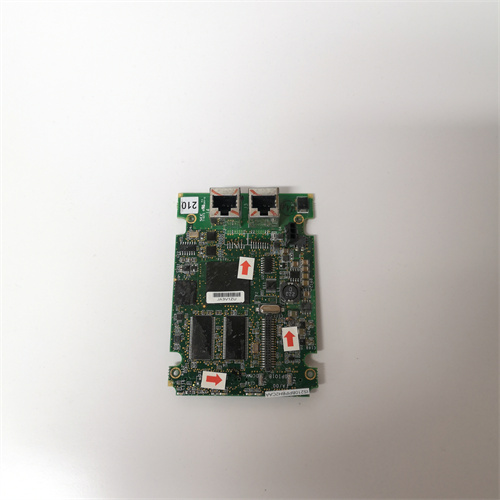

多协议通信与集成

支持Ethernet、Modbus等标准工业协议,可与DCS、PLC等系统无缝集成。支持热插拔功能,便于现场维护和模块更换,减少停机时间。

技术参数

电气参数

输入电压:24V DC(部分信息提及18V DC,需以官方文档为准)。

输出频率:100kHz(特定应用场景下的技术指标)。

环境适应性

工作温度范围:-40°C至+70°C,满足极端工业环境需求。

湿度要求:5%至95%(非冷凝),适应高湿度环境。

物理特性

安装方式:机架安装,结构紧凑便于集成。

防护等级:采用工业级材料和元件,适应高温、振动、粉尘等恶劣条件。

应用场景

能源电力领域

用于燃气轮机、蒸汽轮机等设备的实时监测与控制,提升系统效率与安全性。在电厂控制系统中保障电力设备高效稳定运行。

工业过程控制

监控压缩机、泵及旋转设备,支持能源传输与生产控制。通过数据采集与处理优化工艺流程,提高生产自动化程度。

大型设备管理

控制和优化工业设备运行,确保高效生产。适用于需要高可靠性和稳定性的复杂工业场景。

GE IS210BPPBH2CAA is the core module of General Electric(GE)Mark VI series control system,mainly used in industrial automation and process control fields.The following are its product details:

Core functions

Control and data processing

As the core control unit of the Mark VI system,the module undertakes the system control logic execution,data processing and communication tasks to ensure accurate and stable operation of the equipment.Supports real-time data processing and complex control algorithms,can efficiently process input/output signals,and realize data interaction between equipment and sensors.

Emergency protection and redundancy support

With emergency protection function,it can quickly cut off power or perform safe operations to prevent equipment damage and production losses.Supports redundant configuration,and can still maintain stable operation of the system when a single module fails to ensure the continuity of industrial production.

Multi-protocol communication and integration

Supports standard industrial protocols such as Ethernet and Modbus,and can be seamlessly integrated with DCS,PLC and other systems.Supports hot-swap function,which is convenient for on-site maintenance and module replacement,reducing downtime.

Technical parameters

Electrical parameters

Input voltage:24V DC(some information mentions 18V DC,which shall be subject to official documents).

Output frequency:100kHz(technical indicators under specific application scenarios).

Environmental adaptability

Operating temperature range:-40°C to+70°C,meeting the needs of extreme industrial environments.

Humidity requirements:5%to 95%(non-condensing),adapting to high humidity environments.

Physical characteristics

Installation method:rack installation,compact structure for easy integration.

Protection level:using industrial-grade materials and components,adapting to harsh conditions such as high temperature,vibration,dust,etc.

Application scenarios

Energy and power field

Used for real-time monitoring and control of equipment such as gas turbines and steam turbines to improve system efficiency and safety.Ensure efficient and stable operation of power equipment in power plant control systems.

Industrial process control

Monitor compressors,pumps and rotating equipment to support energy transmission and production control.Optimize process flow through data acquisition and processing to improve the degree of production automation.

Large equipment management

Control and optimize the operation of industrial equipment to ensure efficient production.Suitable for complex industrial scenarios that require high reliability and stability.