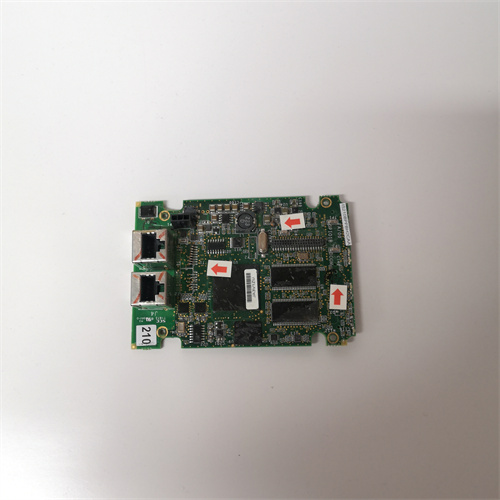

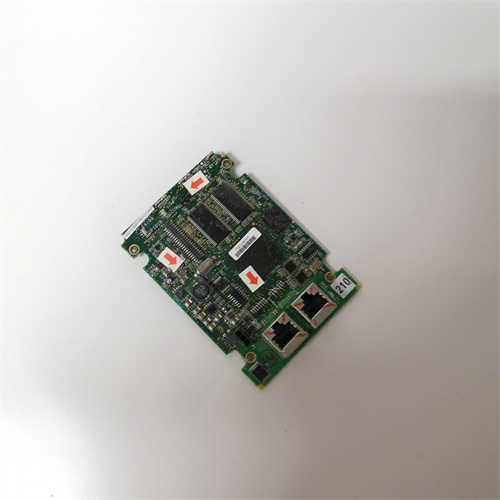

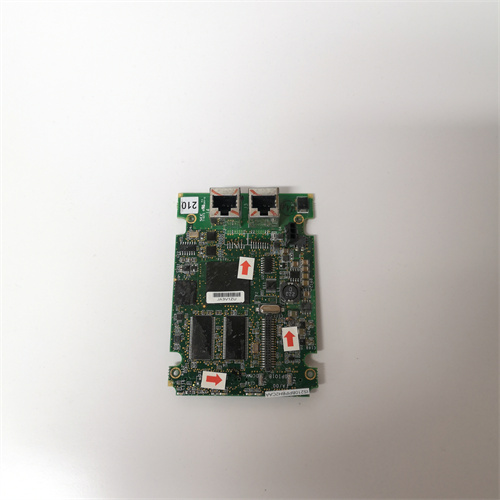

描述

GE IS220PHRAH1A是一款高性能工业自动化模块,专为复杂工业环境设计,具有以下核心功能与技术特点:

一、核心功能与技术参数

高精度信号处理

-支持高精度信号采集与处理,确保数据准确性和可靠性,适用于对实时性和稳定性要求严苛的工业场景。

灵活的配置能力

-提供多种配置选项,用户可根据具体应用需求(如工业自动化、过程控制等)调整参数,适应不同工况。

坚固耐用的设计

-采用工业级抗干扰与防护设计,适用于恶劣环境(如高温、高湿或电磁干扰强的场景),具备长期稳定运行能力。

I/O模块特性

-作为Mark VIe Speedtronic燃气轮机控制系统的关键组件,负责数据采集与控制指令传输,支持与主控系统无缝集成。

二、典型应用场景

工业自动化

-用于生产线控制,提升生产效率与产品质量,例如机器人协作、电机控制等。

过程控制

-在化工、制药、水处理等行业中,监测温度、压力、流量等参数,确保工艺流程稳定。

能源管理

-应用于电力、石油天然气行业,监控设备运行状态,优化能源分配与效率。

机器人与通讯系统

-支持机器人网络通讯,具备冗余双电源输入、高速数据转发(千兆带宽)及存储转发机制,适用于智能工厂的实时数据交互。

三、设计优势

宽兼容性:支持多种工业协议(如基金会现场总线、PROFIBUS-DP),可接入第三方设备。

扩展性:通过模块化设计,可扩展为更大规模控制系统的核心组件。

低维护成本:内置自诊断功能,通过前面板LED显示故障信息,简化维护流程。

GE IS220PHRAH1A is a high-performance industrial automation module designed for complex industrial environments.It has the following core functions and technical features:

I.Core functions and technical parameters

High-precision signal processing

-Supports high-precision signal acquisition and processing to ensure data accuracy and reliability,suitable for industrial scenarios with strict requirements on real-time and stability.

Flexible configuration capabilities

-Provides a variety of configuration options.Users can adjust parameters according to specific application requirements(such as industrial automation,process control,etc.)to adapt to different working conditions.

Rugged design

-Adopts industrial-grade anti-interference and protection design,suitable for harsh environments(such as high temperature,high humidity or strong electromagnetic interference),with long-term stable operation capabilities.

I/O module features

-As a key component of the Mark VIe Speedtronic gas turbine control system,it is responsible for data acquisition and control command transmission,and supports seamless integration with the main control system.

II.Typical application scenarios

Industrial automation

-Used for production line control to improve production efficiency and product quality,such as robot collaboration,motor control,etc.

Process control

-In the chemical,pharmaceutical,water treatment and other industries,monitor parameters such as temperature,pressure,flow,etc.to ensure the stability of the process.

Energy management

-Applied to the power,oil and gas industries to monitor the operating status of equipment and optimize energy distribution and efficiency.

Robots and communication systems

-Support robot network communication,with redundant dual power input,high-speed data forwarding(gigabit bandwidth)and storage and forwarding mechanism,suitable for real-time data interaction in smart factories.

3.Design advantages

Wide compatibility:supports multiple industrial protocols(such as Foundation Fieldbus,PROFIBUS-DP),and can be connected to third-party devices.

Scalability:Through modular design,it can be expanded to the core components of larger-scale control systems.

Low maintenance cost:built-in self-diagnosis function,display fault information through the front panel LED,simplifying the maintenance process.