描述

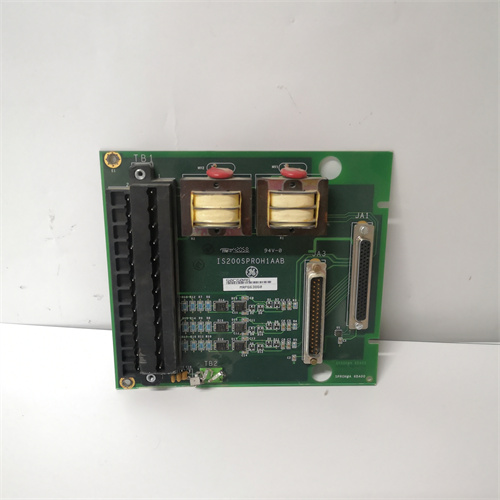

GE IS220PPROS1B是通用电气(GE)旗下的一款紧急涡轮保护I/O模块,专为燃气轮机和汽轮机的高可靠性安全控制设计,属于Mark VIe系列控制系统的核心组件。以下是其产品简介:

一、核心功能与应用场景

紧急保护与实时监测

该模块用于监测涡轮机运行中的关键参数(如转速、压力、温度等),在检测到超速、过压或异常工况时触发紧急停机,防止设备损坏或安全事故。其快速响应时间(毫秒级)确保保护机制的及时激活。

冗余容错设计(TMR)

采用三重模件冗余(TMR)架构,通过三个独立模块的多数表决机制实现故障自检与容错,符合SIL 3安全完整性等级,适用于核电、石油化工等对可靠性要求严苛的场景。

兼容性与扩展性

支持与主控系统(如PTUR模块)协同工作,可集成至分布式控制系统中,兼容RS-232/RS-422等通信协议,适用于发电厂、工业设施及大型涡轮机设备。

二、技术参数与性能

电源输入:24V DC至32V DC,典型功耗12.5W。

工作温度:-40°C至85°C,防护等级IP65(部分型号)。

继电器通道:12路离散输出,支持硬超速保护逻辑。

通信接口:2个以太网端口(IONet协议),支持冗余通信路径。

三、设计特点

模块化与易维护性

采用模块化设计,支持热插拔,可快速更换故障模块而无需停机;LED指示灯实时显示运行状态,简化故障诊断流程。

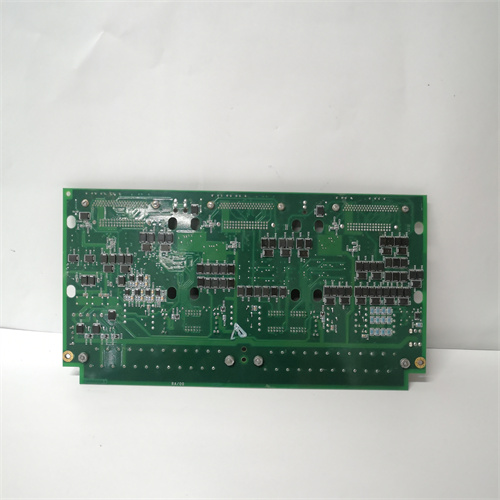

高精度信号处理

支持模拟量与数字量混合输入,具备信号滤波、标度变换功能,适用于复杂工业环境的信号采集。

安全认证

通过CE、UL等国际认证,符合核电、化工等行业安全标准。

GE IS220PPROS1B is an emergency turbine protection I/O module from General Electric(GE).It is designed for high-reliability safety control of gas turbines and steam turbines and is a core component of the Mark VIe series control system.The following is a product introduction:

I.Core functions and application scenarios

Emergency protection and real-time monitoring

This module is used to monitor key parameters(such as speed,pressure,temperature,etc.)in turbine operation,and trigger emergency shutdown when overspeed,overpressure or abnormal operating conditions are detected to prevent equipment damage or safety accidents.Its fast response time(millisecond level)ensures timely activation of the protection mechanism.

Redundant fault-tolerant design(TMR)

Adopting triple modular redundancy(TMR)architecture,fault self-detection and fault tolerance are achieved through the majority voting mechanism of three independent modules,which meets the SIL 3 safety integrity level and is suitable for scenarios with strict reliability requirements such as nuclear power and petrochemicals.

Compatibility and scalability

Supports collaboration with the main control system(such as PTUR module),can be integrated into distributed control systems,compatible with RS-232/RS-422 and other communication protocols,suitable for power plants,industrial facilities and large turbine equipment.

2.Technical parameters and performance

Power input:24V DC to 32V DC,typical power consumption 12.5W.

Operating temperature:-40°C to 85°C,protection level IP65(some models).

Relay channel:12 discrete outputs,support hard overspeed protection logic.

Communication interface:2 Ethernet ports(IONet protocol),support redundant communication paths.

3.Design features

Modularity and easy maintenance

Adopting modular design,supporting hot plugging,the faulty module can be quickly replaced without stopping;the LED indicator shows the operating status in real time,simplifying the fault diagnosis process.

High-precision signal processing

Supports mixed input of analog and digital quantities,with signal filtering and scale conversion functions,suitable for signal acquisition in complex industrial environments.

Safety certification

Passed CE,UL and other international certifications,and complies with the safety standards of nuclear power,chemical and other industries.