描述

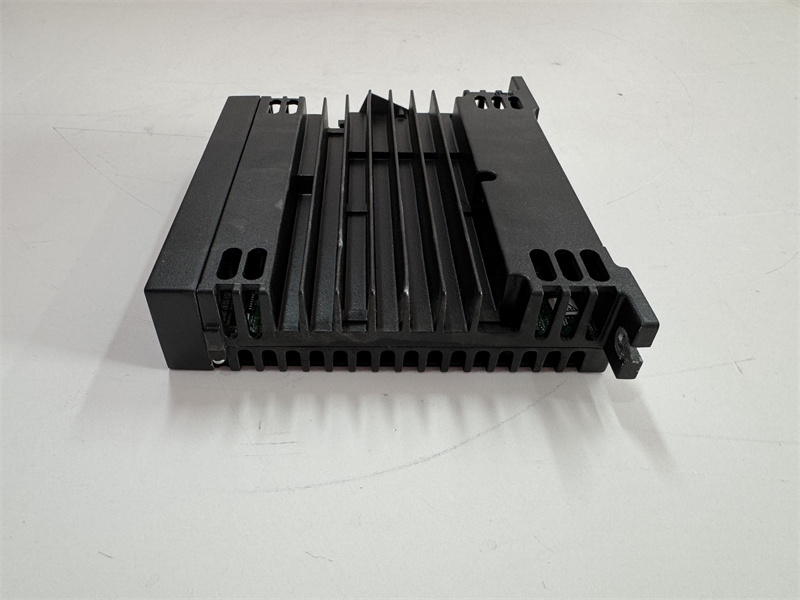

GE IS220UCSAH1A是一款高性能嵌入式控制器模块,专为工业自动化和控制系统设计,尤其适用于燃气轮机、蒸汽轮机及电力系统的管理。以下是其产品简介:

一、核心功能与技术参数

处理器与操作系统

-处理器:采用飞思卡尔8349(Power QUICC II Pro)嵌入式处理器,运行频率667 MHz,支持多任务处理与复杂控制逻辑。

-操作系统:基于QNX Neutrino实时多任务操作系统,确保高可靠性和低延迟。

通信与接口

-以太网接口:支持2个10/100/1000 Mbps以太网端口,兼容工业协议(如Modbus TCP/IP、PROFINET),用于UDH(单元数据高速公路)连接;附加3个以太网端口用于IONet通信。

-扩展接口:支持CAN总线、RS-232/RS-485串口,可灵活接入不同设备。

-光纤接口:可选配1-2路155M光纤接口,支持冗余双网拓扑与长距离通信(60km以上)。

环境适应性

-工作温度:-30℃至65℃(部分型号支持-40℃至70℃),无需风扇散热。

-防护等级:IP30防护,适用于工业级恶劣环境。

-认证标准:符合NFPA 1类2区防爆认证,满足危险区域应用需求。

存储与内存

-程序存储:2GB闪存,支持远程升级与配置备份。

-数据存储:16GB内存,满足实时数据处理与日志记录需求。

二、应用场景

工业自动化:生产线控制、机器人协作、设备监控与故障诊断。

电力与能源:燃气轮机/蒸汽轮机控制、电网状态监测、电厂SCADA系统。

智能制造:高精度运动控制、伺服驱动器接口、智能工厂数据采集。

过程控制:化工生产流程优化、温度压力闭环控制、质量检测。

三、技术优势

冗余设计:支持三重冗余架构,提升系统可用性与可靠性。

模块化扩展:可与其他Mark VIe系统组件(如I/O模块、电源模块)无缝集成。

实时性:667 MHz处理器与QNX系统的结合,确保毫秒级响应速度。

维护友好:前面板LED指示灯(如“链路/操作”“电源”“诊断”)实时反馈系统状态,简化故障排查。

四、硬件规格

尺寸与重量:204×152×55 mm,0.21-1.2 kg(不同型号差异)。

安装方式:基座安装或DIN导轨固定,支持机柜密集布局(相邻安装最多3个模块)。

电源:18-36 V DC输入,功耗12 W。

GE IS220UCSAH1A is a high-performance embedded controller module designed for industrial automation and control systems,especially for the management of gas turbines,steam turbines and power systems.The following is a brief introduction to its product:

I.Core functions and technical parameters

Processor and operating system

-Processor:Adopts Freescale 8349(Power QUICC II Pro)embedded processor,running at 667 MHz,supporting multi-tasking and complex control logic.

-Operating system:Based on QNX Neutrino real-time multi-tasking operating system,ensuring high reliability and low latency.

Communication and interface

-Ethernet interface:Supports 2 10/100/1000 Mbps Ethernet ports,compatible with industrial protocols(such as Modbus TCP/IP,PROFINET),for UDH(Unit Data Highway)connection;additional 3 Ethernet ports for IONet communication.

-Expansion interface:Supports CAN bus,RS-232/RS-485 serial port,which can flexibly connect to different devices.

-Fiber optic interface:1-2 155M fiber optic interfaces are optional,supporting redundant dual network topology and long-distance communication(over 60km).

Environmental adaptability

-Operating temperature:-30℃to 65℃(some models support-40℃to 70℃),no fan heat dissipation required.

-Protection level:IP30 protection,suitable for industrial harsh environments.

-Certification standard:Meets NFPA Class 1 Zone 2 explosion-proof certification to meet application requirements in hazardous areas.

Storage and memory

-Program storage:2GB flash memory,supporting remote upgrades and configuration backup.

-Data storage:16GB memory to meet real-time data processing and logging requirements.

2.Application scenarios

Industrial automation:production line control,robot collaboration,equipment monitoring and fault diagnosis.

Power and energy:gas turbine/steam turbine control,power grid status monitoring,power plant SCADA system.

Intelligent manufacturing:high-precision motion control,servo drive interface,smart factory data acquisition.

Process control:chemical production process optimization,temperature and pressure closed-loop control,quality inspection.

3.Technical advantages

Redundant design:supports triple redundant architecture to improve system availability and reliability.

Modular expansion:can be seamlessly integrated with other Mark VIe system components(such as I/O modules,power modules).

Real-time performance:the combination of 667 MHz processor and QNX system ensures millisecond response speed.

Maintenance-friendly:front panel LED indicators(such as”link/operation”,”power”,”diagnosis”)provide real-time feedback on system status and simplify troubleshooting.

4.Hardware specifications

Dimensions and weight:204×152×55 mm,0.21-1.2 kg(different models vary).

Installation method:base installation or DIN rail fixing,support cabinet dense layout(up to 3 modules installed adjacently).

Power supply:18-36 V DC input,power consumption 12 W.