描述

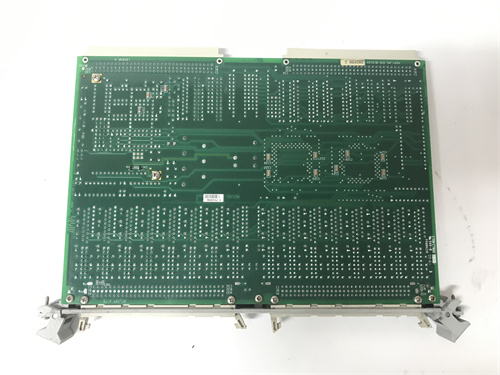

GE MIGIIQI55E00HI00是一款高性能工业电源模块,专为复杂工业环境设计,具备高效率、宽范围兼容性及高可靠性。以下是其核心功能与技术特性概述:

一、核心功能与定位

电源转换

-输入输出:支持宽电压输入(85-264V AC),输出24V DC/10A稳压电源,适用于工业控制器、传感器及执行机构供电。

-效率与功率:满载效率≥90%,功率密度高,尺寸紧凑(约150mm×80mm×40mm)。

保护与安全

-多重防护:集成过流、过压、短路、过温保护,支持输入反接保护及输出短路自恢复功能。

-EMC兼容性:通过工业级电磁兼容测试,抗干扰能力强,适用于噪声复杂的工厂环境。

环境适应性

-宽温工作:-40℃至+70℃宽温范围,满足极端气候条件需求。

-防护等级:IP55防尘防水设计,符合工业设备防护标准。

二、技术参数与性能

电气特性

-输入电压:85-264V AC(50/60Hz)

-输出电压:24V DC±2%(可定制其他电压等级)

-纹波噪声:≤50mVp-p

-动态响应:负载变化时电压恢复时间<10ms。

通信与扩展

-协议支持:兼容Modbus RTU/ASCII、CANopen通信协议,可远程监控电压、电流、温度等参数。

-接口配置:4个数字输入/输出(DI/DO)接口,支持设备状态反馈与控制信号交互。

认证与标准

-符合IEC 60947-5-2、UL 508C、EN 60204-1等国际标准,确保多地区合规应用。

三、应用场景与优势

工业自动化

-为PLC、伺服驱动器、变频器等核心设备供电,保障生产线稳定运行。

-适用于机器人、数控机床、包装机械等高精度场景。

能源与通信

-为通信基站、光伏逆变器提供可靠电源,支持不间断供电需求。

-用于轨道交通信号系统,满足高可靠性要求。

医疗与安全设备

-为医疗影像设备、安防监控系统供电,确保连续运行与数据安全。

四、技术优势

高效率与节能:采用同步整流技术,降低能耗,减少设备散热需求。

模块化设计:支持并联冗余配置,提升系统可用性。

智能监控:通过通信接口实现远程故障诊断与维护,降低停机时间。

GE MIGIIQI55E00HI00 is a high-performance industrial power module designed for complex industrial environments with high efficiency,wide range compatibility and high reliability.The following is an overview of its core functions and technical features:

I.Core functions and positioning

Power conversion

-Input and output:supports wide voltage input(85-264V AC),outputs 24V DC/10A regulated power supply,suitable for powering industrial controllers,sensors and actuators.

-Efficiency and power:full load efficiency≥90%,high power density,compact size(about 150mm×80mm×40mm).

Protection and safety

-Multiple protection:integrated over-current,over-voltage,short-circuit,over-temperature protection,supports input reverse connection protection and output short-circuit self-recovery function.

-EMC compatibility:passed industrial-grade electromagnetic compatibility test,strong anti-interference ability,suitable for factory environments with complex noise.

Environmental adaptability

-Wide temperature operation:-40℃to+70℃wide temperature range,meeting the needs of extreme climate conditions.

-Protection level:IP55 dustproof and waterproof design,in line with industrial equipment protection standards.

2.Technical parameters and performance

Electrical characteristics

-Input voltage:85-264V AC(50/60Hz)

-Output voltage:24V DC±2%(other voltage levels can be customized)

-Ripple noise:≤50mVp-p

-Dynamic response:voltage recovery time<10ms when load changes.

Communication and expansion

-Protocol support:compatible with Modbus RTU/ASCII,CANopen communication protocols,can remotely monitor parameters such as voltage,current,temperature,etc.

-Interface configuration:4 digital input/output(DI/DO)interfaces,support device status feedback and control signal interaction.

Certification and standards

-Comply with international standards such as IEC 60947-5-2,UL 508C,EN 60204-1,etc.,to ensure compliance applications in multiple regions.

3.Application scenarios and advantages

Industrial automation

-Power core equipment such as PLC,servo drive,inverter,etc.to ensure stable operation of production lines.

-Suitable for high-precision scenarios such as robots,CNC machine tools,packaging machinery,etc.

Energy and communication

-Provide reliable power for communication base stations and photovoltaic inverters to support uninterrupted power supply needs.

-Used in rail transit signal systems to meet high reliability requirements.

Medical and safety equipment

-Power medical imaging equipment and security monitoring systems to ensure continuous operation and data security.

4.Technical advantages

High efficiency and energy saving:Synchronous rectification technology is used to reduce energy consumption and reduce equipment heat dissipation requirements.

Modular design:Supports parallel redundant configuration to improve system availability.

Intelligent monitoring:Remote fault diagnosis and maintenance are achieved through communication interfaces to reduce downtime.