描述

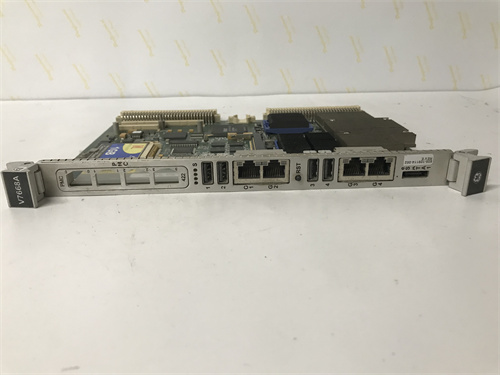

GE V7668A-1310B0 350-9310007668-131020 B产品详情

一、产品概述

GE V7668A-1310B0 350-9310007668-131020 B是通用电气(GE)推出的一款高性能工业控制模块,主要用于工业自动化、过程控制及嵌入式系统应用。该模块以高可靠性、灵活性和强大的通信能力为核心,适用于复杂的工业环境。

二、核心功能

多协议通信支持

支持多种工业通信协议(如RS485、Modbus RTU、CAN等),可与上位系统或其他设备无缝集成,实现高效数据交互。

具备以太网接口,支持实时数据传输与远程监控。

高性能处理能力

采用先进的处理器技术,能够快速处理大量数据,满足高要求的自动化任务。

支持多任务并行处理,提升系统响应速度。

工业级可靠性

采用工业级元器件,适应宽温、高湿、振动等极端环境。

支持冗余设计,确保系统在故障情况下仍能稳定运行。

灵活的扩展性

提供多种输入输出接口,支持数字量、模拟量信号的采集与控制。

可通过扩展模块增加功能,满足不同应用场景的需求。

安全性与防护

具备数据加密与用户权限管理功能,防止非法访问与数据泄露。

支持硬件级安全防护,确保系统在恶劣环境下的安全性。

三、技术参数

输入信号类型:支持数字量、模拟量输入,兼容多种传感器信号。

输出类型:支持数字量、模拟量输出,可驱动执行器。

工作温度:-40°C至85°C(工业级宽温范围)。

防护等级:IP20(适用于室内安装)。

通信接口:以太网、RS485、CAN等。

电源要求:24V DC(典型工业控制电压)。

尺寸与重量:紧凑型设计,便于安装与部署。

四、应用场景

工业自动化

用于生产线监控、设备控制、数据采集等场景,提升生产效率与质量。

支持机器人控制与自动化设备集成。

能源行业

应用于电力分配、风电、太阳能发电等场景,实现电力系统的监控与优化。

支持与GE Mark VI等系统集成,用于涡轮控制与励磁调节。

交通运输

在铁路、公路、港口等交通设施的自动化控制系统中应用,提升运行效率与安全性。

支持交通信号控制与智能调度。

楼宇自动化

用于楼宇的空调系统、照明系统、安防系统等,提高能源使用效率,创造舒适、安全的环境。

支持远程监控与故障诊断。

水处理

在水厂、污水处理厂的自动化控制系统中,实现水质监测、流量控制等功能。

支持数据采集与远程管理。

GE V7668A-1310B0 350-9310007668-131020 B Product Details

I.Product Overview

GE V7668A-1310B0 350-9310007668-131020 B is a high-performance industrial control module launched by General Electric(GE),mainly used for industrial automation,process control and embedded system applications.With high reliability,flexibility and powerful communication capabilities as the core,this module is suitable for complex industrial environments.

II.Core Functions

Multi-protocol Communication Support

Supports a variety of industrial communication protocols(such as RS485,Modbus RTU,CAN,etc.),which can be seamlessly integrated with the host system or other devices to achieve efficient data interaction.

Equipped with Ethernet interface,it supports real-time data transmission and remote monitoring.

High-performance processing capability

Adopting advanced processor technology,it can quickly process large amounts of data to meet high-demand automation tasks.

Supports multi-task parallel processing to improve system response speed.

Industrial-grade reliability

Use industrial-grade components to adapt to extreme environments such as wide temperature,high humidity,and vibration.

Supports redundant design to ensure that the system can still operate stably in the event of a fault.

Flexible scalability

Provides a variety of input and output interfaces to support the acquisition and control of digital and analog signals.

Functions can be added through expansion modules to meet the needs of different application scenarios.

Security and protection

With data encryption and user authority management functions to prevent illegal access and data leakage.

Support hardware-level security protection to ensure the security of the system in harsh environments.

III.Technical parameters

Input signal type:supports digital and analog inputs,and is compatible with a variety of sensor signals.

Output type:supports digital and analog outputs,and can drive actuators.

Working temperature:-40°C to 85°C(industrial wide temperature range).

Protection level:IP20(suitable for indoor installation).

Communication interface:Ethernet,RS485,CAN,etc.

Power requirement:24V DC(typical industrial control voltage).

Size and weight:Compact design,easy to install and deploy.

IV.Application scenarios

Industrial automation

Used in production line monitoring,equipment control,data collection and other scenarios to improve production efficiency and quality.

Support robot control and automation equipment integration.

Energy industry

Applied to power distribution,wind power,solar power generation and other scenarios to achieve power system monitoring and optimization.

Support integration with GE Mark VI and other systems for turbine control and excitation regulation.

Transportation

Applied in the automation control system of transportation facilities such as railways,highways,and ports to improve operating efficiency and safety.

Support traffic signal control and intelligent scheduling.

Building automation

Used in the air conditioning system,lighting system,security system,etc.of the building to improve energy efficiency and create a comfortable and safe environment.

Support remote monitoring and fault diagnosis.

Water treatment

In the automation control system of water plants and sewage treatment plants,realize water quality monitoring,flow control and other functions.

Support data collection and remote management.