描述

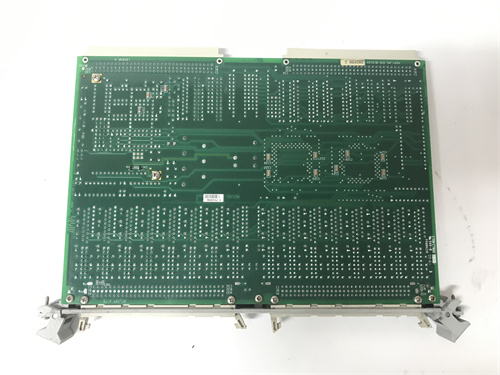

GE VMIVME-3122是一款高性能的VME总线板卡,专为工业自动化、过程控制及数据采集系统设计,以下为其核心产品详情:

一、核心功能

高精度模数转换

16位分辨率:提供高精度数据转换能力,适用于需要精细测量的工业场景。

多通道输入:支持16、32或64路差分/单端模拟输入,满足多传感器数据采集需求。

可编程增益:支持x1或x10增益,适应不同量程的信号输入。

灵活的扫描模式

自动扫描:可编程通道块大小和缓冲区大小,支持连续或突发模式运行。

高速扫描速率:高性能选件下可达381Hz至100kHz,标准性能选件下为381Hz至50kHz。

多模式操作

支持自动扫描、数据突发、外部同步等模式,适应不同工业控制场景。

工业级兼容性

直接连接信号调理板:可与VMIC信号调理电路板系列无缝集成,处理热电偶、热电阻、应变计等传感器输出。

多种触发方式:支持自由运行或外部/内部触发,满足复杂控制逻辑需求。

二、技术参数

A/D转换范围:±2.5V、±5V、±10V、0至+5V、0至+10V。

数据缓冲器:16至1,024字双端口数据缓冲器,支持高速数据存储与传输。

扩展性:支持多个扩展槽,便于系统升级。

总线标准:符合VME64x标准,兼容多种处理器架构。

通信接口:提供串行接口、并行接口和以太网接口,支持RS485、Modbus RTU、CAN等协议。

操作系统支持:兼容VxWorks、QNX等实时操作系统。

三、应用场景

工业自动化

适用于生产线监控、设备状态诊断、质量追溯等场景,实现多传感器数据的高精度采集与分析。

过程控制

在化工、电力、冶金等行业中,用于温度、压力、流量等关键参数的实时监测与控制。

数据采集系统

支持大规模数据采集与存储,适用于需要长期记录工业过程数据的场景。

培训模拟器与实验室仪器

提供高精度模拟信号输入,适用于工业控制系统培训与实验测试。

GE VMIVME-3122 is a high-performance VME bus card designed for industrial automation,process control and data acquisition systems.The following are its core product details:

1.Core functions

High-precision analog-to-digital conversion

16-bit resolution:Provides high-precision data conversion capabilities,suitable for industrial scenarios requiring fine measurement.

Multi-channel input:Supports 16,32 or 64 differential/single-ended analog inputs to meet multi-sensor data acquisition needs.

Programmable gain:Supports x1 or x10 gain to adapt to signal inputs of different ranges.

Flexible scanning mode

Automatic scanning:Programmable channel block size and buffer size,supporting continuous or burst mode operation.

High-speed scanning rate:381Hz to 100kHz with high-performance option,381Hz to 50kHz with standard performance option.

Multi-mode operation

Supports automatic scanning,data burst,external synchronization and other modes to adapt to different industrial control scenarios.

Industrial-grade compatibility

Direct connection to signal conditioning board:can be seamlessly integrated with VMIC signal conditioning circuit board series to process sensor outputs such as thermocouples,thermal resistors,strain gauges,etc.

Multiple triggering modes:support free running or external/internal triggering to meet complex control logic requirements.

II.Technical parameters

A/D conversion range:±2.5V,±5V,±10V,0 to+5V,0 to+10V.

Data buffer:16 to 1,024 word dual-port data buffer,supporting high-speed data storage and transmission.

Scalability:supports multiple expansion slots for easy system upgrades.

Bus standard:complies with VME64x standard and is compatible with multiple processor architectures.

Communication interface:provides serial interface,parallel interface and Ethernet interface,supports RS485,Modbus RTU,CAN and other protocols.

Operating system support:compatible with real-time operating systems such as VxWorks and QNX.

III.Application scenarios

Industrial automation

Suitable for production line monitoring,equipment status diagnosis,quality traceability and other scenarios,to achieve high-precision acquisition and analysis of multi-sensor data.

Process control

In the chemical,electric power,metallurgical and other industries,it is used for real-time monitoring and control of key parameters such as temperature,pressure,and flow.

Data acquisition system

Supports large-scale data acquisition and storage,suitable for scenarios where long-term recording of industrial process data is required.

Training simulators and laboratory instruments

Provide high-precision analog signal input,suitable for industrial control system training and experimental testing.