描述

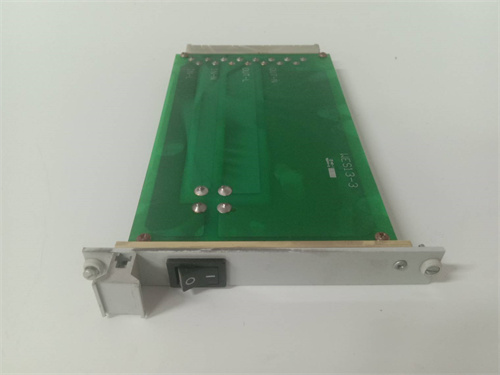

GE WESCOM D200 VME技术工控解析:高性能工业自动化系统核心模块

一、产品概述

GE WESCOM D200 VME是基于VME总线架构的工业自动化核心模块,集成电源接口、可编程逻辑控制器(PLC)、通信接口等功能,适用于工业控制、过程自动化、机械驱动等场景。其设计强调高可靠性、扩展性和模块化,支持冗余配置与预编程功能,可适配多种工业协议(如Ethernet/IP、Profinet)及硬件设备。

二、核心功能与技术特性

1.电源接口模块

高性能电源设计:支持110V-380V输入电压,输出功率范围5W-130W,采用电路保护技术(如过流、过压保护),确保工业环境下的稳定供电。

热插拔支持:允许在不停机状态下更换模块,减少维护停机时间。

2.可编程逻辑控制器(PLC)

控制逻辑执行:负责数据采集、运算、控制输出及网络通信,支持梯形图(LAD)和功能块图(FBD)编程语言。

预编程功能:内置模块化程序库,覆盖卷绕、层压、压光、模切等工业流程,用户可直接调用或修改。

3.通信与扩展性

多协议支持:兼容Ethernet/IP、Profinet等工业协议,支持用户自定义以太网协议,可连接RFID标签站等外部设备。

VME总线集成:通过VME总线实现高速数据传输与设备互联,支持系统扩展与定制。

4.冗余设计

1:1热冗余:双模块协同工作,实时同步状态信息,实现无扰动切换(Bumpless Transfer),保障系统可用性达99.999%(年停机时间仅6分钟)。

故障容错:通过冗余控制电路与高速通信通道(串行/并行)确保主备模块步调一致。

三、技术参数

参数规格

总线架构VMEbus

输入电压110V-380V AC/DC

输出功率5W-130W

通信协议Ethernet/IP,Profinet,用户自定义协议

编程语言梯形图、功能块图

冗余方式1:1热冗余

环境温度-20°C至60°C

防护等级IP30(工业级抗尘防滴)

保修期1年

GE WESCOM D200 VME technical industrial control analysis:core module of high-performance industrial automation system

1.Product Overview

GE WESCOM D200 VME is an industrial automation core module based on the VME bus architecture,integrating power interface,programmable logic controller(PLC),communication interface and other functions.It is suitable for industrial control,process automation,mechanical drive and other scenarios.Its design emphasizes high reliability,scalability and modularity,supports redundant configuration and pre-programming functions,and can be adapted to a variety of industrial protocols(such as Ethernet/IP,Profinet)and hardware devices.

2.Core functions and technical characteristics

1.Power supply interface module

High-performance power supply design:supports 110V-380V input voltage,output power range is 5W-130W,and uses circuit protection technology(such as overcurrent and overvoltage protection)to ensure stable power supply in industrial environments.

Hot-swap support:allows module replacement without shutdown,reducing maintenance downtime.

2.Programmable logic controller(PLC)

Control logic execution:Responsible for data acquisition,calculation,control output and network communication,and supports ladder diagram(LAD)and functional block diagram(FBD)programming languages.

Pre-programming function:built-in modular program library,covering industrial processes such as winding,lamination,calendering,die-cutting,etc.,which users can call or modify directly.

3.Communication and Extensibility

Multi-protocol support:compatible with industrial protocols such as Ethernet/IP and Profinet,supports user-defined Ethernet protocols,and can connect to external devices such as RFID tag stations.

VME bus integration:high-speed data transmission and device interconnection are achieved through VME bus,supporting system expansion and customization.

4.Redundant design

1:1 Thermal redundancy:Dual modules work together,real-time synchronization of status information,realize Bumpless Transfer,and ensure system availability up to 99.999%(annual downtime is only 6 minutes).

Fault fault tolerance:Ensure the pace of the main and spare modules is consistent through redundant control circuits and high-speed communication channels(serial/parallel).

3.Technical parameters

Parameters Specifications

Bus architecture VMEbus

Input voltage 110V-380V AC/DC

Output power 5W-130W

Communication Protocol Ethernet/IP,Profinet,User-defined Protocol

Programming language ladder diagram,function block diagram

Redundancy method 1:1 hot redundancy

Ambient temperature-20°C to 60°C

Protection level IP30(industrial grade dust-resistant and drip-resistant)

Warranty period 1 year