描述

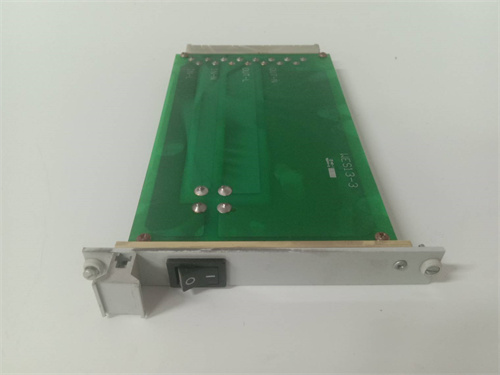

产品概述

GE WESDAC D20A/0511-0101是一款模拟输入模块,专为工业自动化系统设计,支持多通道信号采集与处理。该模块采用分布式架构,分为WESTERM D20A(终端模块)和WESDAC D20A(数据处理模块),通过D.20链路通信协议与主处理器协同工作,适用于电力、能源、钢铁、化工等领域的高精度数据采集需求。

技术参数

输入通道

通道数量:最多支持32个模拟输入,可通过适配器模块扩展为电压或电流输入。

电压范围:1 V、5 V、10 V(单极或双极)。

电流范围:通过分流电阻支持任意共模电流输入,提供润湿源回路输入。

通信与接口

通信协议:支持DNP3协议和HDLC协议,通过D.20链路菊花链连接主处理器。

接口类型:

DB 9连接器:用于D.20链路通信及电源传输。

维护端口:通过DB 9连接器支持VT 100终端或仿真器通信,便于诊断与调试。

电气保护

浪涌保护:内置电容器和变阻器,提供SWC(浪涌耐受能力)和脉冲保护。

电源滤波:通过无源元件滤波和熔断器保护,确保稳定供电。

物理规格

安装方式:19英寸机架安装,所有现场布线连接至WESTERM D20A模块。

模块化设计:WESDAC D20A可独立更换,不影响现场布线。

核心功能特点

分布式处理架构

实时数据采集:靠近现场设备部署,减少信号传输延迟,提升控制响应速度。

智能微处理器:每个I/O模块内置微处理器,负责数据处理与通信,减轻主处理器负载。

高精度与稳定性

抗干扰设计:采用隔离电路和屏蔽措施,适应工业环境中的电磁干扰。

宽温运行:未明确标注具体温度范围,但符合工业级标准(通常-40°C至70°C)。

灵活配置

输入适配器:支持电压或电流输入的独立配置,兼容不同传感器类型。

地址跳线:通过跳线块设置模块地址,适配D.20链路的分布式系统。

典型应用场景

电力系统

监测变电站或发电厂的电压、电流、温度等关键参数。

钢铁与轧管行业

控制轧机、加热炉等设备的工艺参数(如压力、流量、温度)。

化工生产

采集反应釜、管道的实时压力、液位等数据,保障生产安全。

能源管理

监控油气开采与加工设备的运行状态及环境参数。

Product Overview

GE WESDAC D20A/0511-0101 is an analog input module designed for industrial automation systems and supports multi-channel signal acquisition and processing.This module adopts a distributed architecture,divided into WESTERM D20A(terminal module)and WESDAC D20A(data processing module).It works in collaboration with the main processor through the D.20 link communication protocol,and is suitable for high-precision data acquisition requirements in the fields of electricity,energy,steel,chemicals,etc.

Technical parameters

Input channel

Number of channels:Supports up to 32 analog inputs,which can be extended to voltage or current inputs through the adapter module.

Voltage range:1 V,5 V,10 V(monopolar or bipolar).

Current range:Supports any common mode current input through shunt resistors,providing wetting source loop input.

Communication and Interface

Communication protocol:supports DNP3 protocol and HDLC protocol,and connects the main processor through D.20 link daisy chain.

Interface type:

DB 9 connector:used for D.20 link communication and power transmission.

Maintenance port:Supports VT 100 terminal or emulator communication through DB 9 connector,which is convenient for diagnosis and debugging.

Electrical protection

Surge protection:Built-in capacitors and rheostats,providing SWC(surge withstandability)and pulse protection.

Power supply filtering:Passive component filtering and fuse protection ensure stable power supply.

Physical specifications

Installation method:19-inch rack mounted,all field wiring is connected to the WESTERM D20A module.

Modular design:WESDAC D20A can be replaced independently without affecting field wiring.

Core functional features

Distributed Processing Architecture

Real-time data acquisition:Deployment close to field equipment,reduce signal transmission delay,and improve control response speed.

Intelligent microprocessor:Each I/O module has a built-in microprocessor,which is responsible for data processing and communication,and reduces the load of the main processor.

High precision and stability

Anti-interference design:Use isolation circuits and shielding measures to adapt to electromagnetic interference in industrial environments.

Wide temperature operation:The specific temperature range is not clearly marked,but it meets industrial-grade standards(usually-40°C to 70°C).

Flexible configuration

Input adapter:Supports independent configuration of voltage or current input,compatible with different sensor types.

Address jumper:Set the module address through the jumper block and adapt to the distributed system of D.20 link.

Typical application scenarios

Power system

Monitor key parameters such as voltage,current,and temperature of substations or power plants.

Steel and pipe rolling industry

Control the process parameters(such as pressure,flow rate,temperature)of rolling mills,heating furnaces and other equipment.

Chemical production

Collect real-time pressure,liquid level and other data of reactors and pipelines to ensure production safety.

Energy Management

Monitor the operating status and environmental parameters of oil and gas mining and processing equipment.