描述

GE IC693CMM321-JK是通用电气(GE)旗下一款高性能工业自动化模块,兼具通信与控制功能,适用于复杂工业场景。以下是其核心功能与技术特点的综合概述:

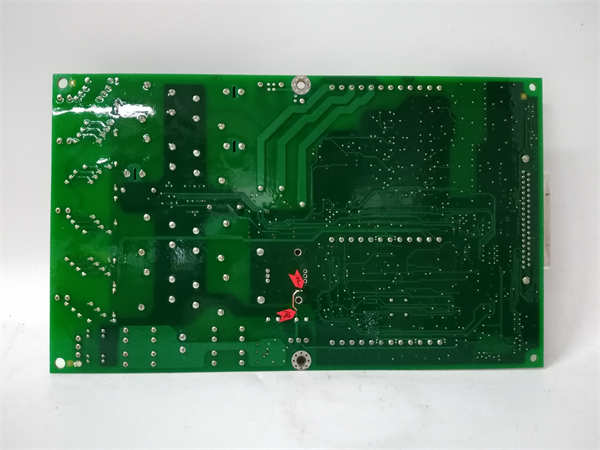

一、产品概述

IC693CMM321-JK是GE Fanuc自动化系列中的核心模块,支持多种通信协议与数据处理功能。其设计紧凑,兼容工业标准安装方式,适用于分布式控制系统(DCS)、可编程逻辑控制器(PLC)扩展及设备间数据交互。

二、技术参数

通信能力

-协议支持:EtherNet/IP、Modbus TCP、Profinet等工业协议,满足不同网络架构需求。

-接口配置:1个自适应10/100Mbps以太网口,支持TCP/IP协议栈。

硬件规格

-尺寸:约120mm×80mm×40mm(长×宽×高),适配标准DIN导轨安装。

-工作环境:

-工作温度:0–55℃,存储温度:-20–70℃。

-电源要求:24V DC,低功耗设计。

数据处理

-支持数字量、模拟量、字符串等多种数据类型,处理速度达650μs(CPU模块特性)。

三、核心功能

通信与扩展

-实现PLC与其他设备(如传感器、上位机)的数据交换,支持分布式控制架构。

-通过配置软件(如Proficy Machine Edition)灵活定义通信规则与协议。

诊断与维护

-实时监测模块状态,LED指示灯显示运行状态,快速定位故障点。

-支持在线监控与调试,提升系统维护效率。

兼容性与扩展性

-可与其他GE硬件(如控制器基座、I/O模块)及第三方设备无缝集成。

-适用于定制化系统设计,满足不同工业场景需求。

四、应用领域

制造业:汽车、电子、食品生产线设备间通信与控制协调。

能源行业:电力、石油天然气领域设备监控与数据管理。

基础设施:交通、水处理系统自动化控制与数据采集。

机器视觉:辅助图像采集卡(如Matrox METEOR2)实现数据传输与处理。

IC698CPE010-JU

IC698PSA100E

GE IC693CMM321-JK is a high-performance industrial automation module under General Electric(GE),which has both communication and control functions and is suitable for complex industrial scenarios.The following is a comprehensive overview of its core functions and technical features:

I.Product Overview

IC693CMM321-JK is a core module in the GE Fanuc automation series,supporting multiple communication protocols and data processing functions.It has a compact design and is compatible with industrial standard installation methods.It is suitable for distributed control systems(DCS),programmable logic controllers(PLC)expansion and data interaction between devices.

II.Technical Parameters

Communication Capability

-Protocol support:EtherNet/IP,Modbus TCP,Profinet and other industrial protocols to meet the needs of different network architectures.

-Interface configuration:1 adaptive 10/100Mbps Ethernet port,supporting TCP/IP protocol stack.

Hardware Specifications

-Size:about 120mm×80mm×40mm(length×width×height),suitable for standard DIN rail installation.

-Working environment:

-Working temperature:0–55℃,storage temperature:-20–70℃.

-Power supply requirement:24V DC,low power consumption design.

Data processing

-Supports multiple data types such as digital,analog,and string,with a processing speed of 650μs(CPU module characteristics).

III.Core functions

Communication and expansion

-Realize data exchange between PLC and other devices(such as sensors and host computers),and support distributed control architecture.

-Flexibly define communication rules and protocols through configuration software(such as Proficy Machine Edition).

Diagnosis and maintenance

-Real-time monitoring of module status,LED indicator lights display operating status,and quickly locate fault points.

-Support online monitoring and debugging to improve system maintenance efficiency.

Compatibility and scalability

-Can be seamlessly integrated with other GE hardware(such as controller base,I/O module)and third-party devices.

-Suitable for customized system design to meet the needs of different industrial scenarios.

IV.Application fields

Manufacturing:Communication and control coordination between equipment in automobile,electronics,and food production lines.

Energy industry:Equipment monitoring and data management in the fields of electricity,oil and gas.

Infrastructure:Automation control and data acquisition of transportation and water treatment systems.

Machine vision:Auxiliary image acquisition cards(such as Matrox METEOR2)to achieve data transmission and processing.