描述

GE IC693MDL940H是一款高性能的工业自动化控制器,结合了可编程逻辑控制器(PLC)与工业计算机的特性,适用于复杂工业控制场景。以下是其核心功能与技术参数的综合概述:

一、核心功能与架构

软PLC技术

-采用软PLC架构,通过软件实现逻辑控制功能,支持用户自定义编程与扩展。

-兼容IEC 61131-3标准,支持图形化(如梯形图、功能块)与文本化(如结构化文本、指令表)编程,提升开发灵活性。

模块化设计

-模块式结构,支持热插拔与灵活扩展,可集成数字量输入/输出、模拟量处理及通讯模块。

-控制室安装,适用于集中式或分布式控制系统。

PAC系统特性

-兼容PAC(可编程自动化控制器)标准,结合PC的开放性与PLC的实时性,支持与主流工业协议(如Profinet、Modbus)无缝对接。

-支持多任务处理与冗余配置,提升系统可靠性与抗干扰能力。

二、技术参数

处理器:基于高性能嵌入式CPU,处理速度达20MHz。

存储容量:程序存储10KB,数据存储20KB。

I/O点数:可扩展至数百点(具体数量需结合模块配置)。

工作电压:220V AC,适应工业电源环境。

认证标准:通过CCC认证,符合工业级防护要求。

三、应用场景

工业过程控制

-温度、压力、流量等模拟量参数的闭环控制,适用于化工、制药、能源等流程行业。

-例如,配合模拟量模块实现温度传感器数据采集与PID调节。

离散控制

-开关量逻辑控制,如电机启停、阀门切换等,广泛应用于机械制造、物流自动化领域。

-支持高速脉冲输出,适用于运动控制(如伺服电机定位)。

智能网络节点

-作为分散式控制节点,通过以太网或现场总线实现与上位机、传感器的实时通信,构建分布式控制系统。

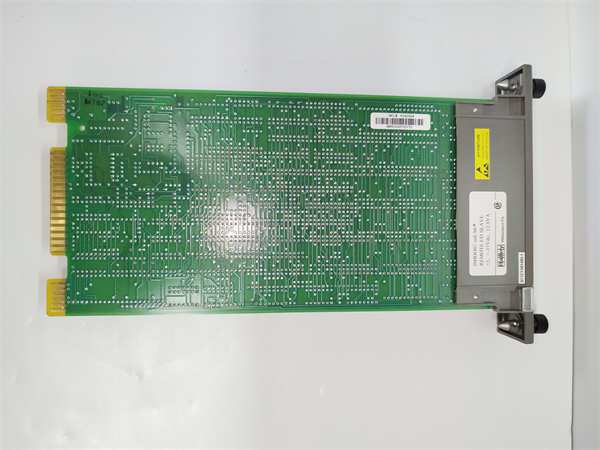

IC695CPU315

IC695CPU315

GE IC693MDL940H is a high-performance industrial automation controller that combines the features of a programmable logic controller(PLC)and an industrial computer,and is suitable for complex industrial control scenarios.The following is a comprehensive overview of its core functions and technical parameters:

I.Core functions and architecture

Soft PLC technology

-Adopting a soft PLC architecture,it implements logic control functions through software and supports user-defined programming and expansion.

-Compatible with IEC 61131-3 standards,supports graphical(such as ladder diagrams,function blocks)and textual(such as structured text,instruction lists)programming,and improves development flexibility.

Modular design

-Modular structure,supports hot plugging and flexible expansion,and can integrate digital input/output,analog processing and communication modules.

-Control room installation,suitable for centralized or distributed control systems.

PAC system features

-Compatible with PAC(Programmable Automation Controller)standards,combining the openness of PCs with the real-time performance of PLCs,and supports seamless docking with mainstream industrial protocols(such as Profinet and Modbus).

-Support multi-tasking and redundant configuration to improve system reliability and anti-interference ability.

2.Technical parameters

Processor:Based on high-performance embedded CPU,processing speed reaches 20MHz.

Storage capacity:10KB for program storage and 20KB for data storage.

Number of I/O points:Expandable to hundreds of points(specific number needs to be combined with module configuration).

Working voltage:220V AC,suitable for industrial power supply environment.

Certification standard:Passed CCC certification and meets industrial protection requirements.

3.Application scenarios

Industrial process control

-Closed-loop control of analog parameters such as temperature,pressure,flow,etc.,suitable for process industries such as chemical,pharmaceutical,and energy.

-For example,with analog modules,temperature sensor data acquisition and PID adjustment are realized.

Discrete control

-Switching logic control,such as motor start and stop,valve switching,etc.,is widely used in mechanical manufacturing and logistics automation.

-Support high-speed pulse output,suitable for motion control(such as servo motor positioning).

Intelligent network node

-As a distributed control node,it can realize real-time communication with the host computer and sensors through Ethernet or field bus to build a distributed control system.