描述

GE IS200BPVCG1BR1是通用电气(GE)旗下一款高性能工业控制模块,适用于复杂工业环境中的电机控制、自动化系统及电力管理。以下是其核心产品特性和应用领域的综合概述:

一、产品概述

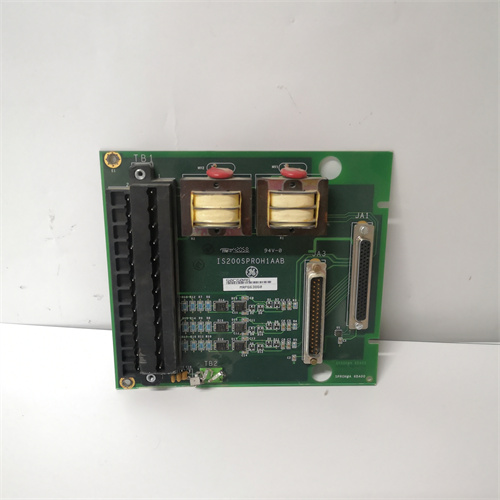

IS200BPVCG1BR1是基于Mark VI Speedtronic系列的核心模块,兼具数字量输出控制与背板扩展功能。其设计融合了高精度矢量控制算法与模块化架构,支持多模式PLC运行、多段速调节及PID控制,适用于工业洗涤设备、制造设备及能源管理等场景。

二、核心功能与技术参数

控制与算法

-矢量控制算法:集成高精度转子磁场定向矢量控制(FOC),支持250%瞬时转矩输出,适用于重载启动和动态响应需求。

-多模式PLC:支持速度、转矩、位置三种控制模式,可通过参数切换实现复杂工艺逻辑控制。

-PID功能:内置自由PID模块,可替代外部控制器,简化系统设计。

扩展与接口

-背板架构:设计为机架系统背板,后部包含21个母连接器,支持多模块扩展;前部提供39个I/O连接器,兼容带状电缆快速连接。

-通信协议:支持RS-232/485、CAN总线及以太网,可实现与PLC、DCS的无缝集成。

-I/O端口:8路可编程输入端口、5路可编程输出端口,兼容±10V模拟信号输入。

环境适应性

-工业级防护:工作温度范围-30℃至+60℃,支持低烟无卤定制型号(830-0LH10),满足严苛环境需求。

-抗干扰设计:采用光耦隔离、阻容滤波及表面贴装技术(SMT),有效抑制电磁干扰。

三、技术规格

电压与功率:支持220V/24V DC输入,额定功率0.75kW至4kW。

频率范围:0-600Hz,低速运行可至0.1rpm,调速范围达1:5000。

尺寸与材质:铝合金外壳,尺寸210mm×140mm×80mm,重量约2.5kg。

四、应用领域

工业控制

-电机调速(变频、软启动、制动)、张力卷绕、同步控制(如拉丝机、纺织设备)。

-自动化生产线、机器人控制、电力分配与谐波治理。

能源与电力

-燃气/蒸汽轮机控制系统、发电厂监控、水处理设备。

-化工、冶金、玻璃制造等重工业领域的设备控制。

特殊行业

-医疗设备、环保监测、轨道交通信号控制。

GE IS200BPVCG1BR1 is a high-performance industrial control module from General Electric(GE),suitable for motor control,automation systems and power management in complex industrial environments.The following is a comprehensive overview of its core product features and application areas:

I.Product Overview

IS200BPVCG1BR1 is a core module based on the Mark VI Speedtronic series,with both digital output control and backplane expansion functions.Its design combines high-precision vector control algorithms with modular architecture,supports multi-mode PLC operation,multi-speed adjustment and PID control,and is suitable for industrial washing equipment,manufacturing equipment and energy management.

II.Core functions and technical parameters

Control and algorithm

-Vector control algorithm:integrated high-precision rotor field oriented vector control(FOC),supports 250%instantaneous torque output,suitable for heavy-load startup and dynamic response requirements.

-Multi-mode PLC:supports three control modes of speed,torque and position,and can achieve complex process logic control through parameter switching.

-PID function:built-in free PID module,which can replace external controller and simplify system design.

Expansion and interface

-Backplane architecture:Designed as a rack system backplane,the rear contains 21 female connectors to support multi-module expansion;the front provides 39 I/O connectors,compatible with ribbon cable quick connection.

-Communication protocol:Supports RS-232/485,CAN bus and Ethernet,and can achieve seamless integration with PLC and DCS.

-I/O port:8 programmable input ports,5 programmable output ports,compatible with±10V analog signal input.

Environmental adaptability

-Industrial-grade protection:The operating temperature range is-30℃to+60℃,and supports low-smoke and halogen-free customized models(830-0LH10)to meet the needs of harsh environments.

-Anti-interference design:Adopts optocoupler isolation,resistor-capacitor filtering and surface mount technology(SMT)to effectively suppress electromagnetic interference.

III.Technical specifications

Voltage and power:Supports 220V/24V DC input,rated power 0.75kW to 4kW.

Frequency range:0-600Hz,low speed operation can be as low as 0.1rpm,speed range up to 1:5000.

Dimensions and materials:aluminum alloy shell,size 210mm×140mm×80mm,weight about 2.5kg.

IV.Application fields

Industrial control

-Motor speed regulation(frequency conversion,soft start,braking),tension winding,synchronous control(such as wire drawing machine,textile equipment).

-Automated production line,robot control,power distribution and harmonic control.

Energy and power

-Gas/steam turbine control system,power plant monitoring,water treatment equipment.

-Equipment control in heavy industrial fields such as chemical,metallurgical,glass manufacturing,etc.

Special industries

-Medical equipment,environmental monitoring,rail transit signal control.