描述

产品简要说明

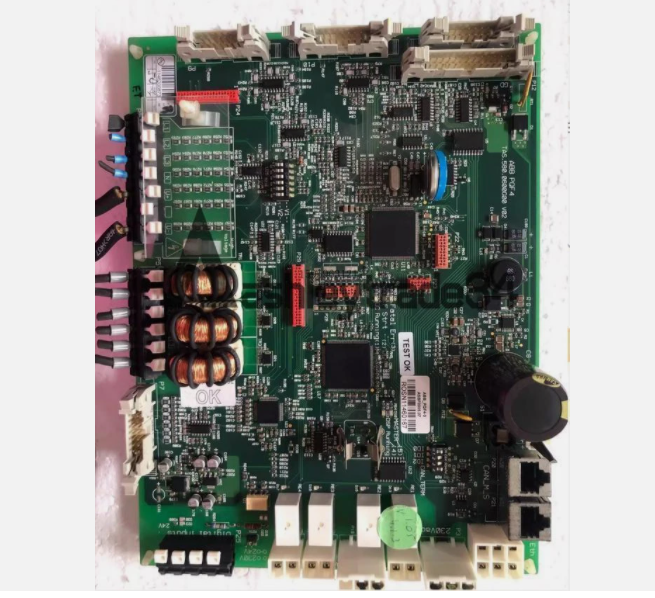

GE DS2020FEBNRX050A是通用电气(GE)专为塑料注射成型设备设计的控制模块,核心功能包括:

工艺参数精准控制:支持温度、压力、速度等关键参数的动态调节

工业网络适配:兼容EtherNet/IP、Profinet等协议,实现设备联网与远程监控

模块化扩展:可集成传感器、驱动器等外围设备,适配不同机型需求

产品详细说明

1.硬件架构与核心组件

控制核心:

基于32位微处理器,支持实时任务调度与多协议通信

内置128MB Flash存储,用于程序与工艺参数存储

I/O接口:

数字I/O:支持256点输入/输出,兼容PLCopen标准

模拟I/O:4路模拟量输入(0-10V/4-20mA),用于温度、压力传感器信号采集

2.工艺控制功能

温度控制:

支持多区温度控制(如模具、料筒、喷嘴),精度±0.5℃

内置PID算法,可自适应调整加热功率

注射成型控制:

实时监控注射压力(最高200MPa)与速度(0-300mm/s)

支持多段注射曲线编程,适配不同材料特性

3.工业网络与通信

协议兼容性:

主站模式支持EtherNet/IP、Profinet,从站模式兼容DeviceNet

支持OPC UA协议数据接口,便于与MES系统集成

技术规格:GE DS2020FEBNRX050A

参数项规格描述

处理器32位微处理器

存储容量128MB Flash

数字I/O 256点(可扩展至512点)

模拟I/O 4路输入(0-10V/4-20mA)

通信协议EtherNet/IP、Profinet、DeviceNet、OPC UA

工作温度-10℃~60℃

防护等级IP65

尺寸190mm×120mm×50mm

核心价值与性能亮点

1.高精度工艺控制

温度均匀性:通过多区PID算法,确保模具各区域温差≤1℃,提升产品表面光洁度

压力补偿:动态调整注射压力以补偿材料粘度变化,减少制品缺陷

2.智能化运维

故障诊断:实时监测传感器断路、电源异常等故障,支持远程报警

数据追溯:记录每批次成型参数与生产时间,支持CSV格式导出

3.绿色节能设计

能耗优化:采用变频驱动技术,加热阶段能耗降低20%

休眠模式:非生产时段自动进入低功耗状态,待机功耗<5W

Product brief description

GE DS2020FEBNRX050A is a control module designed by General Electric(GE)for plastic injection molding equipment,with core functions including:

Precise control of process parameters:supports dynamic adjustment of key parameters such as temperature,pressure,and speed.

Industrial network adaptation:compatible with EtherNet/IP,Profinet and other protocols,realizing device networking and remote monitoring

Modular expansion:can integrate sensors,drivers and other peripheral devices to meet different machine needs

Product details

1.Hardware architecture and core components

Control core:

Based on 32-bit microprocessor,supports real-time task scheduling and multi-protocol communication

Built-in 128MB Flash storage for program and process parameter storage

I/O interface:

Digital I/O:Supports 256-point input/output,compatible with PLCopen standard

Analog I/O:4 analog inputs(0-10V/4-20mA),used for temperature and pressure sensor signal acquisition

2.Process control function

Temperature control:

Supports multi-zone temperature control(such as molds,barrels,nozzles),with an accuracy of±0.5℃

Built-in PID algorithm,adaptively adjusting heating power

Injection molding control:

Real-time monitoring of injection pressure(up to 200MPa)and speed(0-300mm/s)

Supports multi-segment injection curve programming,adapts to different material characteristics

3.Industrial networks and communications

Protocol Compatibility:

The master mode supports EtherNet/IP and Profinet,and the slave mode is compatible with DeviceNet

Supports OPC UA protocol data interface for easy integration with MES system

Technical Specifications:GE DS2020FEBNRX050A

Parameters Specification Description

Processor 32-bit microprocessor

Storage capacity 128MB Flash

Digital I/O 256 points(scalable to 512 points)

Analog I/O 4-channel input(0-10V/4-20mA)

Communication Protocols EtherNet/IP,Profinet,DeviceNet,OPC UA

Working temperature-10℃~60℃

Protection level IP65

Dimensions:190mm×120mm×50mm

Core Valuesand Performance Highlights

1.High-precision process control

Temperature uniformity:Through the multi-zone PID algorithm,ensure the temperature difference between the mold area is≤1℃,and improve the surface smoothness of the product

Pressure compensation:Dynamically adjust the injection pressure to compensate for material viscosity changes and reduce product defects

2.Intelligent operation and maintenance

Fault diagnosis:Real-time monitoring of sensor circuit breakers,power abnormalities and other faults,and supports remote alarm

Data traceability:Record the molding parameters and production time of each batch,and support CSV format export

3.Green energy-saving design

Energy consumption optimization:adopt variable frequency drive technology,reduce energy consumption in the heating stage by 20%

Sleep mode:Automatically enters the low-power state during non-production period,standby power consumption<5W