描述

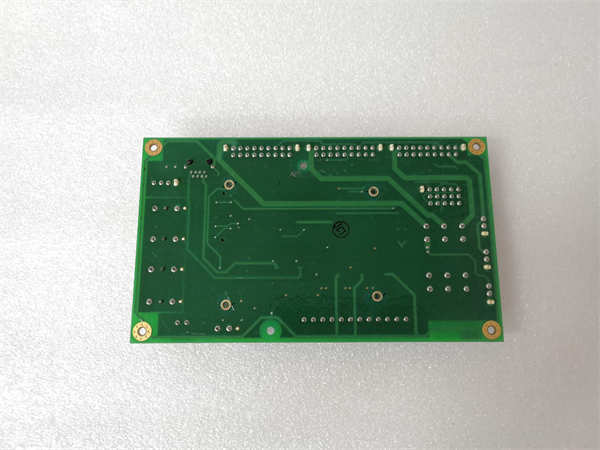

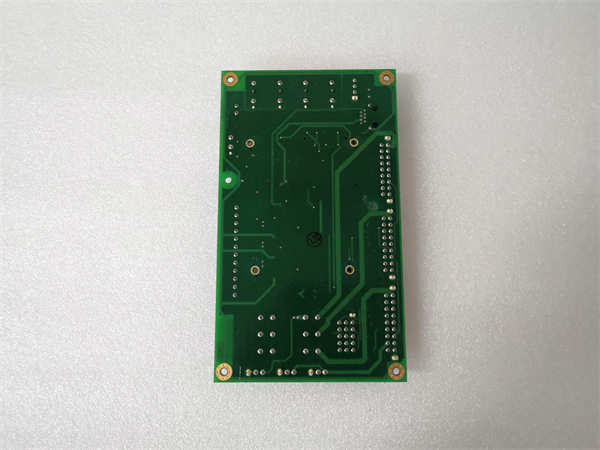

GENERAL ELECTRIC DS215UDSAG1AZZ产品简要说明

GE DS215UDSAG1AZZ是通用电气(GE)专为涡轮控制系统设计的核心模块,核心功能包括:

模拟量处理:支持电压、电流、热电阻信号输入,集成16通道内存地址分配与标度变换

工业级兼容性:适配GE Mark V Speedtronic控制系统,兼容IC695ALG600系列I/O模块

极端环境适配:耐受-40℃至85℃温度,通过工业电磁干扰测试,支持24V DC冗余供电

产品详细说明

1.硬件架构与核心组件

信号处理单元:

采用16位ADC转换器,支持±0.1%精度模拟量输入(电压/电流/热电阻)

内置标度变换算法,可独立配置每个通道的信号类型与输出范围

通信与控制接口:

支持VME总线协议,与GE Speedtronic控制系统无缝对接

提供8K双端口SRAM接口,确保实时数据读写可靠性

2.功能特性与工业适配性

动态响应能力:

处理速度15Hz,支持多任务并行处理,满足涡轮机实时控制需求

内置定时功能,可配置1ms/10ms/100ms时钟脉冲触发控制逻辑

环境适应性设计:

防护等级IP65,适用于户外或高湿度工业环境

双路24V DC冗余电源输入,支持热插拔切换与电压稳压

技术规格:GE DS215UDSAG1AZZ

参数项规格描述

信号输入类型电压(0-10V)、电流(4-20mA)、热电阻(PT100)

处理速度15Hz

内存地址16通道(AI1-AI16)

工作电压220V AC/24V DC(冗余输入)

工作温度-40℃至+85℃

防护等级IP65

尺寸10cm×5cm×2cm

核心价值与性能亮点

1.涡轮控制中枢

高精度信号管理:16位ADC分辨率与独立标度变换功能,确保燃气轮机转速、温度等关键参数的精准采集

系统兼容性:深度适配GE Mark V Speedtronic架构,降低集成复杂度与维护成本

2.极端环境稳定性

宽温运行:在-40℃极寒环境中仍保持稳定输出,适用于北极地区能源项目

抗干扰设计:屏蔽外壳与信号隔离技术,适应强电磁干扰环境(如变电站)

3.智能诊断与维护

故障自检功能:实时监测模块状态,通过LED指示灯(绿色:正常/红色:故障)快速定位问题

数据追溯能力:支持历史数据记录,便于分析设备运行趋势与优化控制策略

应对挑战,创造价值

1.高精度控制需求

案例:某燃气电厂部署该模块后,涡轮机转速控制误差从±2%降至±0.5%,年燃料消耗降低15%

2.复杂工业环境适应性

案例:沙漠地区石油钻井平台采用该模块,85℃高温下连续运行5年,未发生因温度导致的故障

DS200RT8AG3AHC

DS200RT8AG3AHC

Product brief description

GE DS215UDSAG1AZZ is a core module designed by General Electric(GE)for turbine control systems,with core functions including:

Analog processing:supports voltage,current,and thermal resistance signal input,integrated 16-channel memory address allocation and scale conversion

Industrial compatibility:adapted to GE Mark V Speedtronic control system,compatible with IC695ALG600 series I/O modules

Extreme environment adaptation:tolerate temperatures of-40℃to 85℃,pass industrial electromagnetic interference test,support 24V DC redundant power supply

Product details

1.Hardware architecture and core components

Signal processing unit:

Adopt 16-bit ADC converter,supports±0.1%accuracy analog input(voltage/current/thermal resistance)

Built-in scale conversion algorithm,which can independently configure the signal type and output range of each channel

Communication and control interface:

Supports VME bus protocol and seamlessly connects with GE Speedtronic control system

Provides 8K dual-port SRAM interface to ensure real-time data read and write reliability

2.Functional characteristics and industrial adaptability

Dynamic response capability:

Processing speed is 15Hz,supports multi-task parallel processing,meets the real-time control needs of turbines

Built-in timing function,can be configured with 1ms/10ms/100ms clock pulse trigger control logic

Environmental adaptability design:

Protection level IP65,suitable for outdoor or high humidity industrial environments

Dual 24V DC redundant power supply input,support hot-swap switching and voltage stabilization

Technical Specifications:GE DS215UDSAG1AZZ

Parameters Specification Description

Signal input type Voltage(0-10V),current(4-20mA),thermal resistance(PT100)

Processing speed 15Hz

Memory address 16 channels(AI1-AI16)

Operating voltage 220V AC/24V DC(redundant input)

Operating temperature-40℃to+85℃

Protection level IP65

Size 10cm×5cm×2cm

Core Valuesand Performance Highlights

1.Turbine Control Center

High-precision signal management:16-bit ADC resolution and independent scale conversion functions ensure accurate collection of key parameters such as gas turbine speed and temperature

System compatibility:Deeply adapted to GE Mark V Speedtronic architecture to reduce integration complexity and maintenance costs

2.Extreme environmental stability

Wide temperature operation:maintain stable output in an extremely cold environment of-40℃,suitable for energy projects in the Arctic region

Anti-interference design:shielded shell and signal isolation technology to adapt to strong electromagnetic interference environments(such as substations)

3.Intelligent diagnosis and maintenance

Fault self-test function:real-time monitoring of module status,quickly locate problems through LED indicators(green:normal/red:fault)

Data traceability:Supports historical data records,facilitates analysis of equipment operation trends and optimized control strategies

Respond to challenges and create value

1.High-precision control requirements

Case:After a gas power plant deploys this module,the turbine speed control error has dropped from±2%to±0.5%,and the annual fuel consumption has been reduced by 15%.

2.Adaptability of complex industrial environments

Case:The oil drilling platform in the desert area uses this module,and operates continuously for 5 years at high temperature of 85℃,without any faults caused by temperature.