描述

产品简要说明

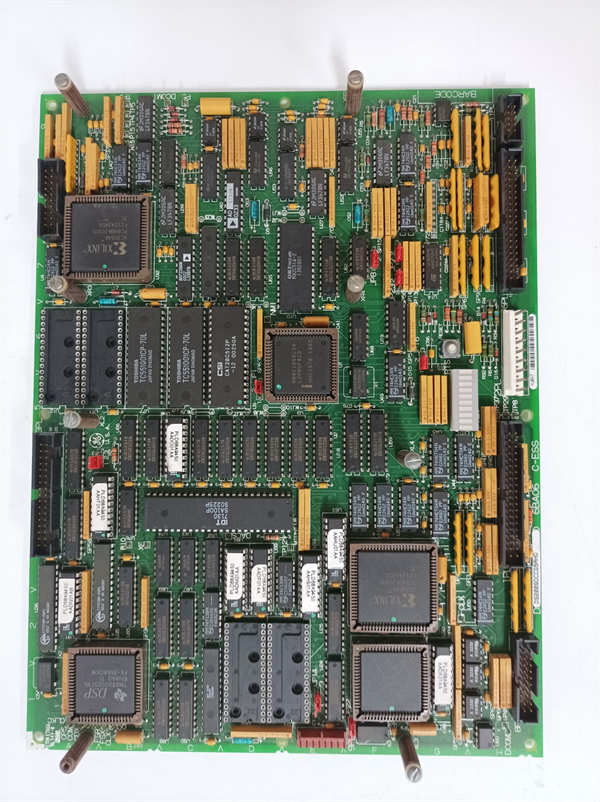

GE DS3800DMEC1D1D是通用电气(GE)专为工业伺服系统设计的驱动控制模块,核心功能包括:

多轴伺服控制:支持同步电机、步进电机及直流无刷电机的精准定位与扭矩调节

工业协议兼容:集成Modbus、Profibus及EtherNet/IP通信协议,实现与PLC、SCADA系统的无缝对接

恶劣环境适应:通过IP65防护认证,耐受-30℃~70℃宽温环境及高湿度场景

产品详细说明

1.硬件架构与核心功能

驱动控制引擎:

多轴协同:支持4轴同步控制,定位精度达±0.01mm(配合编码器反馈)

扭矩调节:动态扭矩输出范围0-500Nm,响应时间<2ms

信号处理能力:

编码器接口:兼容增量式(ABZ)、绝对值(Sin/Cos)及BiSS-C编码器

模拟量输入:4-20mA电流环与0-10V电压信号双通道输入

2.通信与扩展能力

协议融合机制:

Modbus主从模式:支持最多32个从站设备,波特率自适应1200-115200 bps

EtherNet/IP集成:通过工业以太网实现运动控制指令下发与状态反馈

数据安全设计:

CRC校验:所有通信帧均采用32位循环冗余校验

紧急制动触发:支持硬线急停与软件急停双重保护

3.工业级可靠性设计

环境适应性:

宽压供电:24V DC(18-36V容差)

抗电磁干扰:符合EN 61000-6-2工业环境抗干扰标准

故障诊断系统:

实时状态监测:电流/电压/温度等16项参数动态显示

自恢复机制:过流、过压等异常后自动复位(可配置延迟时间)

技术规格:GE DS3800DMEC1D1D

参数项规格描述

驱动类型伺服电机驱动(同步/步进/直流无刷)

通信接口2xRS-485、1xGigabit Ethernet(EtherNet/IP)

控制轴数4轴同步控制

定位精度±0.01mm(配合高分辨率编码器)

工作温度-30℃~70℃

防护等级IP65(可选IP67防护罩)

核心价值与性能亮点

1.动态响应能力

高速控制:指令执行延迟<2ms,适用于高速分拣、精密装配等场景

柔性配置:支持单轴独立控制与多轴协调运动模式切换

2.协议兼容性

工业网络集成:单模块实现Modbus与EtherNet/IP协议转换,降低系统集成复杂度

编码器适配:兼容主流编码器类型,减少传感器选型限制

3.严苛环境适配

极端温度耐受:-30℃低温下仍保持0.02mm定位精度(误差<5%)

抗振动设计:通过MIL-STD-810G标准(5-500Hz,2g振动幅值)

DS3800NB1F1B1A

DS3800NB1F1B1A

Product brief description

GE DS3800DMEC1D1D is a drive control module designed by General Electric(GE)for industrial servo systems.The core functions include:

Multi-axis servo control:supports precise positioning and torque adjustment of synchronous motors,stepper motors and brushless DC motors

Industrial protocol compatibility:Integrate Modbus,Profibus and EtherNet/IP communication protocols to achieve seamless connection with PLC and SCADA systems

Harsh environment adaptation:Passed IP65 protection certification,tolerate wide temperature environment and high humidity scenarios

Product details

1.Hardware architecture and core functions

Drive control engine:

Multi-axis collaboration:supports 4-axis synchronous control,positioning accuracy up to±0.01mm(with encoder feedback)

Torque adjustment:Dynamic torque output range 0-500Nm,response time<2ms

Signal processing capability:

Encoder interface:compatible with incremental(ABZ),absolute value(Sin/Cos)and BiSS-C encoder

Analog input:4-20mA current loop and 0-10V voltage signal dual channel input

2.Communication and expansion capabilities

Protocol fusion mechanism:

Modbus master-slave mode:supports up to 32 slave devices,baud rate adaptable 1200-115200 bps

EtherNet/IP integration:Motion control command issuance and status feedback through industrial Ethernet

Data security design:

CRC verification:All communication frames use 32-bit cyclic redundancy verification

Emergency braking trigger:Supports dual protection of hardwire emergency stop and software emergency stop

3.Industrial-grade reliability design

Environmental adaptability:

Wide voltage power supply:24V DC(18-36V tolerance)

Anti-electromagnetic interference:Comply with EN 61000-6-2 industrial environment anti-interference standard

Troubleshooting system:

Real-time status monitoring:dynamic display of 16 parameters such as current/voltage/temperature

Self-recovery mechanism:Automatic reset after abnormalities such as overcurrent and overvoltage(the delay time can be configured)

Technical Specifications:GE DS3800DMEC1D1D

Parameters Specification Description

Drive type servo motor drive(synchronous/stepped/DC brushless)

Communication interface 2xRS-485,1xGigabit Ethernet(EtherNet/IP)

Number of control axes 4-axis synchronization control

Positioning accuracy±0.01mm(with high resolution encoder)

Working temperature-30℃~70℃

Protection level IP65(optional IP67 protective cover)

Core Valuesand Performance Highlights

1.Dynamic response capability

High-speed control:The command execution delay is less than 2ms,suitable for high-speed sorting,precision assembly and other scenarios

Flexible configuration:Supports single-axis independent control and multi-axis coordinated motion mode switching

2.Protocol Compatibility

Industrial network integration:Single module realizes Modbus and EtherNet/IP protocol conversion,reducing system integration complexity

Encoder adaptation:compatible with mainstream encoder types,reducing sensor selection restrictions

3.Strict environmental adaptation

Extreme temperature tolerance:0.02mm positioning accuracy is maintained at low temperatures of-30℃(Error<5%)

Vibration resistance design:Passed by MIL-STD-810G standard(5-500Hz,2g vibration amplitude)