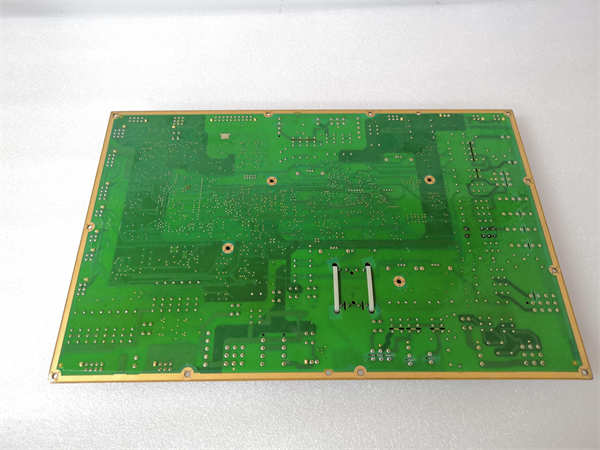

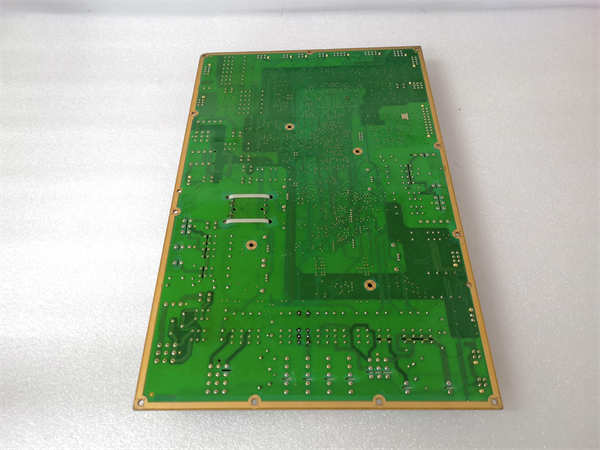

描述

产品简要说明

GE DS3800HCMC1A1B是通用电气(GE)专为工业自动化系统设计的控制模块,核心功能包括:

多协议通信:支持Modbus、Profibus等工业协议,兼容GE Mark VIe控制系统架构

模块化扩展:通过IC695ALG600模拟量输入模块实现16通道信号采集与标度变换

工业级可靠性:IP65防护等级,耐受-40℃至85℃极端温度,支持冗余电源输入

产品详细说明

1.硬件架构与核心组件

处理器与通信接口:

基于PowerPC架构处理器,主频500MHz,支持多任务并行处理

提供双以太网端口(10/100Base-TX)及Profibus DP接口,支持冗余配置

电源与保护机制:

双路24V DC冗余电源输入,支持热插拔切换

过流保护与电压稳压功能,通过IEC 61000-6-4抗干扰测试

2.功能特性与工业适配性

模拟量处理能力:

集成IC695ALG600模块,支持电压(0-10V)、电流(4-20mA)、热电阻(PT100)信号输入

提供16位整型与32位浮点数据转换,支持通道独立标度变换

实时控制与诊断:

内置定时功能,通过1ms/10ms/100ms时钟脉冲实现延时控制

LED状态指示(琥珀色:警告/红色:故障),支持快速故障定位

技术规格:GE DS3800HCMC1A1B

参数项规格描述

处理器架构PowerPC(500MHz)

通信接口2x以太网(10/100Base-TX)、1xProfibus DP

协议支持Modbus TCP/RTU、Profibus DP

电压输入24V DC(双路冗余)

工作温度-40℃至85℃

防护等级IP65

尺寸35mm(标准工业模块尺寸)

核心价值与性能亮点

1.工业自动化中枢

信号处理精度:16位ADC分辨率支持±0.1%精度,满足高精度过程控制需求

多协议融合:在燃气轮机控制系统中实现Profibus DP与Modbus协议设备的无缝对接

2.极端环境适配性

宽温运行:-40℃低温下仍保持稳定运行,适用于极寒地区燃气轮机控制

抗电磁干扰设计:屏蔽外壳与信号隔离技术,适应强电磁环境(如变电站)

3.智能诊断与维护

故障定位效率:LED状态指示与诊断日志结合,缩短故障排查时间50%

预测性维护支持:通过实时负载监测实现设备寿命预测,减少非计划停机

DS3800XTFP1E1C

DS3800XTFP1E1C

Product brief description

GE DS3800HCMC1A1B is a control module designed by General Electric(GE)for industrial automation systems,with core functions including:

Multi-protocol communication:supports industrial protocols such as Modbus and Profibus,and is compatible with GE Mark VIe control system architecture

Modular expansion:16-channel signal acquisition and scale conversion are realized through IC695ALG600 analog input module

Industrial-grade reliability:IP65 protection level,withstand extreme temperatures of-40℃to 85℃,support redundant power input

Product details

1.Hardware architecture and core components

Processor and communication interface:

Based on PowerPC architecture processor,main frequency is 500MHz,and supports multi-task parallel processing

Provides dual Ethernet ports(10/100Base-TX)and Profibus DP interfaces,supporting redundant configuration

Power and protection mechanism:

Dual 24V DC redundant power supply input,support hot-swap switching

Overcurrent protection and voltage regulation function,passed IEC 61000-6-4 anti-interference test

2.Functional characteristics and industrial adaptability

Analog quantity processing capability:

Integrated IC695ALG600 module,supports voltage(0-10V),current(4-20mA),thermal resistance(PT100)signal input

Provides 16-bit integer and 32-bit floating-point data conversion,supporting channel independent scale transformation

Real-time control and diagnosis:

Built-in timing function,delay control is achieved through 1ms/10ms/100ms clock pulse

LED status indicator(Amber:Warning/Red:Fault),supports rapid fault location

Technical specifications:GE DS3800HCMC1A1B

Parameters Specification Description

Processor Architecture PowerPC(500MHz)

Communication interface 2x Ethernet(10/100Base-TX),1xProfibus DP

Protocol supports Modbus TCP/RTU,Profibus DP

Voltage input 24V DC(dual redundancy)

Operating temperature-40℃to 85℃

Protection level IP65

Dimensions 35mm(standard industrial module size)

Core Valuesand Performance Highlights

1.Industrial automation center

Signal processing accuracy:16-bit ADC resolution supports±0.1%accuracy,meeting the requirements of high-precision process control

Multi-protocol fusion:seamless connection between Profibus DP and Modbus protocol equipment in gas turbine control system

2.Extreme environmental adaptability

Wide temperature operation:maintain stable operation at low temperature-40℃,suitable for gas turbine control in extremely cold areas

Anti-electromagnetic interference design:shielded shell and signal isolation technology to adapt to strong electromagnetic environments(such as substations)

3.Intelligent diagnosis and maintenance

Fault location efficiency:LED status indication combined with diagnostic logs to shorten the troubleshooting time by 50%

Predictive maintenance support:Real-time load monitoring to achieve equipment life forecasting and reduce unplanned downtime