描述

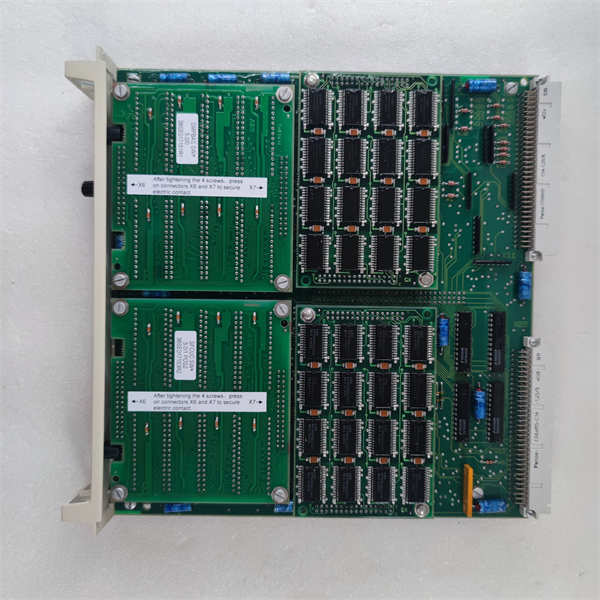

GESPAC GESMEM-12D是霍尼韦尔(Honeywell)旗下的一款PLC插件板,专为工业自动化控制系统设计,尤其适用于分布式控制系统(DCS)和安全仪表系统(SIS)。以下是其核心功能与技术特点的综合概述:

一、产品定位与兼容性

系统适配

该模块是霍尼韦尔Experion PKS(C200、C300)系列的核心组件之一,兼容TK/TC/CC系统及FSC安全仪表系统,支持FOUNDATION Fieldbus、PROFIBUS等工业协议。

扩展性

作为PC板插件板,可灵活扩展至不同控制架构中,与霍尼韦尔其他模块(如IS200、DS200系列)无缝协同,构建分布式控制网络。

二、技术参数

硬件特性

-接口类型:支持多路数字量输入/输出及模拟量信号处理,具体点数需结合系统配置。

-通信速率:FOUNDATION Fieldbus协议下通信速率可达5Mbps,响应时间低于20ms。

环境适应性

-工作温度:-40°C至85°C(宽温型号),满足极端工业场景需求。

-防护等级:符合工业级电磁兼容标准,抗干扰能力突出。

三、核心功能

数据采集与处理

用于采集现场设备信号(如温度、压力、流量),并执行逻辑运算与控制算法,支持HART协议智能设备集成。

安全与冗余

在FSC系统中,模块具备安全认证(SIL等级),支持冗余配置以提升系统可用性,适用于高风险工业场景。

集成服务

支持远程诊断与维护功能,可通过上位机系统实时监控模块状态,降低停机风险。

四、应用场景

能源与电力

用于发电厂锅炉控制、汽轮机保护及电网调度系统,实现高精度数据采集与实时响应。

化工与石油天然气

适配反应器温度控制、管道压力监测及紧急停车系统(ESD),满足安全仪表功能需求。

智能制造

集成于自动化产线中,实现设备状态监测、工艺参数优化及故障预测。

五、技术优势

可靠性:通过霍尼韦尔严苛的工业级测试认证,MTBF(平均无故障时间)超过10万小时。

灵活性:支持定制化扩展,可适配不同规模的控制系统需求。

服务支持:提供从选型、调试到售后维护的全流程技术支持,缩短系统部署周期。

GESPAC GESMEM-12D is a PLC plug-in board from Honeywell,designed for industrial automation control systems,especially for distributed control systems(DCS)and safety instrument systems(SIS).The following is a comprehensive overview of its core functions and technical features:

I.Product positioning and compatibility

System adaptation

This module is one of the core components of Honeywell’s Experion PKS(C200,C300)series,compatible with TK/TC/CC systems and FSC safety instrument systems,and supports industrial protocols such as FOUNDATION Fieldbus and PROFIBUS.

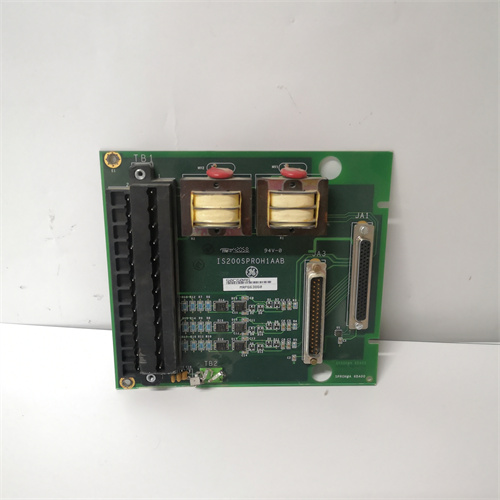

Extensibility

As a PC board plug-in board,it can be flexibly expanded to different control architectures,and seamlessly cooperate with other Honeywell modules(such as IS200,DS200 series)to build a distributed control network.

II.Technical parameters

Hardware features

-Interface type:supports multi-channel digital input/output and analog signal processing,and the specific number of points needs to be combined with system configuration.

-Communication rate:The communication rate under the FOUNDATION Fieldbus protocol can reach 5Mbps,and the response time is less than 20ms.

Environmental adaptability

-Working temperature:-40°C to 85°C(wide temperature model),meeting the needs of extreme industrial scenarios.

-Protection level:meets industrial-grade electromagnetic compatibility standards and has outstanding anti-interference capabilities.

III.Core functions

Data acquisition and processing

Used to collect field equipment signals(such as temperature,pressure,flow),and perform logical operations and control algorithms,supporting HART protocol intelligent device integration.

Safety and redundancy

In the FSC system,the module has safety certification(SIL level),supports redundant configuration to improve system availability,and is suitable for high-risk industrial scenarios.

Integration services

Support remote diagnosis and maintenance functions,and can monitor the module status in real time through the host system to reduce the risk of downtime.

IV.Application scenarios

Energy and power

Used for power plant boiler control,turbine protection and power grid dispatching systems to achieve high-precision data acquisition and real-time response.

Chemical and oil and gas

Adapt to reactor temperature control,pipeline pressure monitoring and emergency shutdown system(ESD)to meet the functional requirements of safety instruments.

Intelligent Manufacturing

Integrated into the automated production line to achieve equipment status monitoring,process parameter optimization and fault prediction.

V.Technical Advantages

Reliability:Passed Honeywell’s rigorous industrial-grade test certification,MTBF(mean time between failures)exceeds 100,000 hours.

Flexibility:Supports customized expansion and can adapt to control system requirements of different scales.

Service Support:Provides full-process technical support from selection,commissioning to after-sales maintenance to shorten the system deployment cycle.