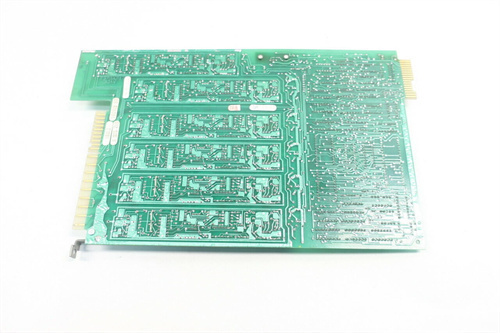

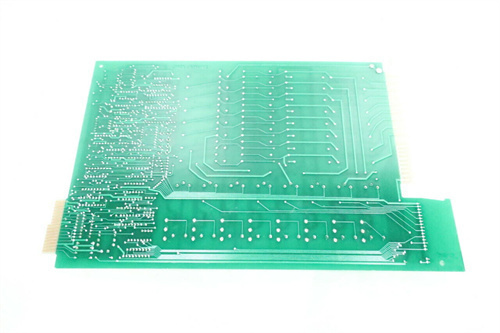

描述

HoloTrak IS8500 232/422是一款专为工业计量领域设计的高精度全息扫描仪,基于Metrologic集团的先进全息技术,结合智能化功能与工业级防护,适用于复杂环境下的精密测量。以下是其核心特性与技术细节的综合解析:

一、产品定位与系列归属

型号:IS8500 232/422

品牌:HoloTrak(由Metrologic集团开发)

系列:IS8000系列

技术特点:采用全息扫描技术,结合自动校准与自动对焦功能,可快速、准确测量机械零部件、汽车零部件、航空零部件等复杂物体的尺寸和形状。

二、核心功能与技术参数

高精度测量

分辨率:基于0.33毫米(0.013英寸)条码宽度的景深区域定义,实际扫描范围可根据标签尺寸和应用动态调整。

精度优势:通过全息技术捕捉材料表面细节,适用于精密加工与质量控制场景。

工业环境适应性

外壳防护:封装在坚固的NEMA-12外壳中,满足工业环境防尘、防溅要求。

安装灵活性:支持全向安装(可选主/辅设置),适用于多场景布局。

智能功能

自动校准:内置算法实现快速校准,减少人工干预需求。

错误预警:可选配无代码/错误代码警告功能,提升数据可靠性。

通信接口:支持RS-232/RS-422协议,兼容主流工业控制系统。

三、应用场景

机械制造:检测机床加工件尺寸公差与表面缺陷。

汽车工业:验证车身零部件装配精度,优化生产流程。

航空航天:测量精密航空部件(如涡轮叶片、复合材料)的几何参数。

科研领域:用于材料形变分析、三维建模等实验研究。

四、技术扩展性

模块化设计:可与其他IS8000系列设备协同工作,构建分布式扫描网络。

数据处理:集成数据采集与分析功能,支持实时输出测量结果至上位机系统。

抗干扰技术:采用电容滤波与软件抗干扰算法(如数字滤波、工频整形采样),提升系统稳定性。

HoloTrak IS8500 232/422 is a high-precision holographic scanner designed for industrial metrology.It is based on Metrologic Group’s advanced holographic technology,combined with intelligent functions and industrial-grade protection,and is suitable for precision measurement in complex environments.The following is a comprehensive analysis of its core features and technical details:

I.Product positioning and series attribution

Model:IS8500 232/422

Brand:HoloTrak(developed by Metrologic Group)

Series:IS8000 series

Technical features:Using holographic scanning technology,combined with automatic calibration and autofocus functions,it can quickly and accurately measure the size and shape of complex objects such as mechanical parts,automotive parts,and aviation parts.

II.Core functions and technical parameters

High-precision measurement

Resolution:Based on the depth of field area definition of 0.33 mm(0.013 inches)barcode width,the actual scanning range can be dynamically adjusted according to the label size and application.

Precision advantage:Capturing material surface details through holographic technology,suitable for precision processing and quality control scenarios.

Industrial environment adaptability

Housing protection:Enclosed in a rugged NEMA-12 housing,it meets the dust and splash-proof requirements of industrial environments.

Installation flexibility:Supports omnidirectional installation(optional primary/secondary settings),suitable for multi-scenario layout.

Intelligent functions

Automatic calibration:Built-in algorithms achieve fast calibration and reduce the need for manual intervention.

Error warning:Optional no-code/error code warning function to improve data reliability.

Communication interface:Supports RS-232/RS-422 protocols and is compatible with mainstream industrial control systems.

III.Application scenarios

Mechanical manufacturing:Detect dimensional tolerances and surface defects of machine tool parts.

Automotive industry:Verify the assembly accuracy of body parts and optimize production processes.

Aerospace:Measure the geometric parameters of precision aviation parts(such as turbine blades and composite materials).

Scientific research:Used for experimental research such as material deformation analysis and 3D modeling.

IV.Technical scalability

Modular design:Can work with other IS8000 series devices to build a distributed scanning network.

Data processing:Integrated data acquisition and analysis functions,support real-time output of measurement results to the host computer system.

Anti-interference technology:capacitor filtering and software anti-interference algorithms(such as digital filtering and power frequency shaping sampling)are used to improve system stability.