描述

产品概述

Johnson Controls MS-NAE5510-3是江森自控(Johnson Controls)推出的网络自动化引擎,属于Metasys MS系列的核心组件,专为大型商业建筑的建筑自动化系统(BAS)和能源管理系统(EMS)设计。其核心功能包括多系统集成、实时控制、能源优化及远程监控,适用于办公楼、医院、大学、工业设施等复杂场景。

技术参数

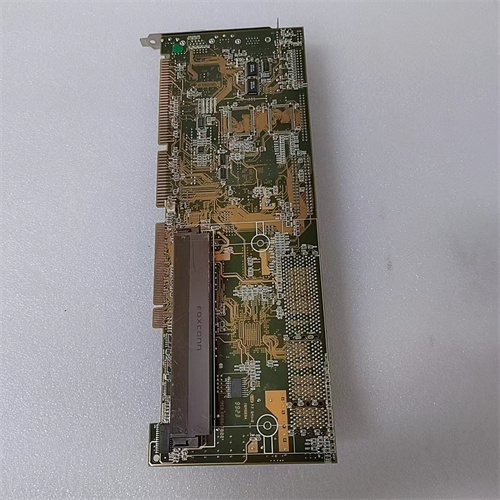

硬件配置

处理器:133 MHz处理速度(部分版本为85 MHz)。

内存:16 GB闪存+2 GB SDRAM(部分型号为6 MB程序容量)。

功耗:50 VA,工作电压24 V AC(支持20-30 V AC范围)。

尺寸:22.4 cm×39.4 cm×27.9 cm,重量2.9 kg。

通信接口

网络端口:1个以太网端口(支持10/100/1000 Mbps),1个LonWorks端口(78 Kbps)。

串行端口:2个RS-232-C、2个RS-485(不同波特率)、2个USB 2.0。

协议支持:BACnet、Modbus、LonWorks、OPC UA。

环境适应性

工作温度:-40°C至85°C(部分版本为0°C至35°C)。

防护等级:未明确标注,但符合工业级抗振动与冲击设计。

认证:UL或CE认证(不同版本可能不同)。

核心功能特点

系统集成与控制

多系统整合:可协调暖通空调(HVAC)、照明、门禁、安全系统等,实现统一监控与管理。

工业自动化兼容性:支持与工厂设备通信,执行复杂控制逻辑。

智能化与扩展性

内置网络服务器:提供用户友好的Web界面,支持远程访问、参数调整及报警管理。

灵活安装:支持控制室安装或DIN导轨安装,适应不同环境需求。

能源管理与优化

实时数据处理:通过高性能处理器快速响应系统需求,优化能源使用效率。

动态调节:根据环境变化自动调整设备运行状态(如温度、光照)。

维护与升级

现场升级:支持调制解调器升级,但需注意升级可能导致部分功能(如寻呼机)失效。

不可维修设计:内部无用户可维修部件,需遵循官方维护指南。

典型应用场景

建筑自动化

大型商业建筑的HVAC系统控制、照明节能管理。

医院手术室环境监测与安全系统联动。

工业控制

制造业生产线设备监控与数据采集。

石油化工厂的分布式能源调度。

智能楼宇

大学校园的能源管理系统集成。

数据中心的温度与电力优化。

Product Overview

Johnson Controls MS-NAE5510-3 is a network automation engine launched by Johnson Controls.It belongs to the core components of the Metasys MS series and is designed for building automation systems(BASs)and energy management systems(EMSs)in large commercial buildings.Its core functions include multi-system integration,real-time control,energy optimization and remote monitoring,and are suitable for complex scenarios such as office buildings,hospitals,universities,and industrial facilities.

Technical parameters

Hardware configuration

Processor:133 MHz processing speed(85 MHz in some versions).

Memory:16 GB flash+2 GB SDRAM(some models are 6 MB program capacity).

Power consumption:50 VA,operating voltage 24 V AC(supports the 20-30 V AC range).

Dimensions:22.4 cm×39.4 cm×27.9 cm,weight 2.9 kg.

Communication interface

Network port:1 Ethernet port(supports 10/100/1000 Mbps),1 LonWorks port(78 Kbps).

Serial ports:2 RS-232-C,2 RS-485(different baud rates),2 USB 2.0.

Protocol support:BACnet,Modbus,LonWorks,OPC UA.

Environmental adaptability

Operating temperature:-40°C to 85°C(0°C to 35°C in some versions).

Protection level:Not clearly marked,but it complies with industrial-grade vibration and impact resistance design.

Certification:UL or CE certification(different versions may vary).

Core functional features

System integration and control

Multi-system integration:can coordinate HVAC,lighting,access control,safety systems,etc.to achieve unified monitoring and management.

Industrial automation compatibility:supports communication with factory equipment and performs complex control logic.

Intelligence and scalability

Built-in network server:provides a user-friendly web interface,supports remote access,parameter adjustment and alarm management.

Flexible installation:Supports control room installation or DIN rail installation to meet different environmental needs.

Energy Management and Optimization

Real-time data processing:quickly respond to system requirements through high-performance processors and optimize energy usage efficiency.

Dynamic adjustment:Automatically adjust the operating status of the equipment(such as temperature and lighting)according to environmental changes.

Maintenance and Upgrade

On-site upgrade:Modem upgrade is supported,but it should be noted that the upgrade may cause some functions(such as pagers)to fail.

Non-repairable design:There are no user-serviceable parts inside,and the official maintenance guide is required.

Typical application scenarios

Building automation

HVAC system control and lighting energy-saving management in large commercial buildings.

The hospital operating room environmental monitoring is linked to the safety system.

Industrial Control

Manufacturing production line equipment monitoring and data collection.

Distributed energy dispatching for petrochemical plants.

Smart Building

Energy management system integration on university campuses.

Temperature and power optimization in data centers.