描述

一、产品概述

KCM-2是K-Tron旗下第二代智能称重控制器,采用模块化设计,集成高速微处理器、高精度A/D转换器和先进的数字滤波算法,可实时处理称重传感器信号,并通过PID控制算法精确调节喂料电机转速或阀门开度,确保物料流量稳定。其核心优势包括:

高精度测量:分辨率可达1:100,000,满足微克级称重需求。

快速响应:采样频率≥100次/秒,适应高速生产线。

抗干扰能力强:有效抑制振动、电磁干扰对称重信号的影响。

灵活通信:支持多种现场总线协议,便于与PLC、DCS、SCADA系统集成。

二、核心功能

高精度称重控制:

实时采集称重传感器信号,通过数字滤波算法消除噪声干扰,输出稳定、准确的重量值。

支持单点或多点校准,适应不同量程和精度要求。

流量控制与调节:

根据设定流量值,通过PID控制算法自动调节喂料电机转速或阀门开度,实现恒流量或变流量控制。

支持批量喂料模式,可预设目标重量,自动完成加料、计量、停止全过程。

多参数监测与显示:

实时显示当前重量、瞬时流量、累计流量、运行时间等关键参数。

支持趋势图绘制,便于分析流量波动规律。

故障诊断与保护:

检测传感器断线、过载、欠载、电机故障等异常情况,并通过LED指示灯或通信接口报警。

提供历史故障记录,支持故障代码查询,快速定位问题根源。

通信与数据交互:

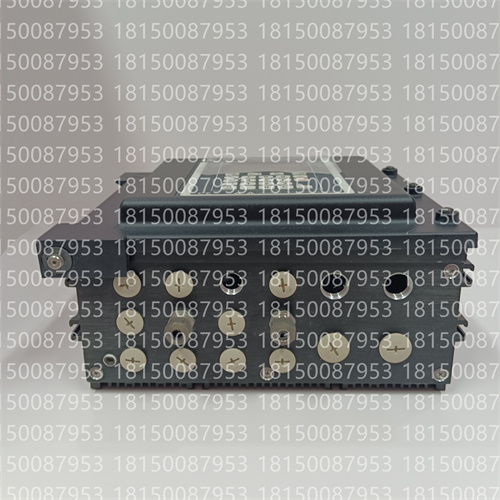

标准接口:RS-232/RS-485串口,支持Modbus RTU协议。

可选接口:以太网(Modbus TCP)、Profibus-DP、DeviceNet、CANopen(需配置扩展模块)。

远程监控:通过上位机软件实现参数设置、状态显示、数据记录等功能。

操作界面与编程:

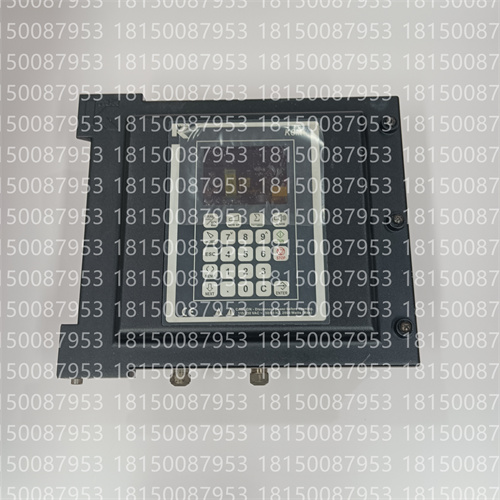

本地操作面板:集成LCD显示屏和按键,支持中文/英文等多语言界面,可进行参数修改、模式切换、校准操作。

编程灵活性:支持自定义控制逻辑,适应复杂工艺流程。

三、技术规格(示例,具体以实物为准)

参数详情

产品类型智能称重控制器

型号标识KCM-2

输入信号称重传感器:4-20mA或0-10V(兼容350Ω或700Ω桥路)

输出信号控制信号:4-20mA(驱动变频器或电机控制器)

称重范围0.1kg-10,000kg(可定制)

分辨率1:100,000(典型值)

采样频率≥100次/秒

控制方式PID控制(支持P、I、D参数独立调整)

通信接口RS-232/RS-485(标配);以太网、Profibus-DP、DeviceNet(可选)

显示与操作LCD显示屏+按键;支持多语言界面

工作电源交流85-265V,50/60Hz或直流24V(需确认型号配置)

环境适应性工作温度:-10℃~+50℃;存储温度:-20℃~+70℃;湿度≤85%RH(无凝露)

防护等级IP20(面板安装)或IP54(机柜安装)

认证标准CE、UL、FCC、RoHS

1.Product Overview

KCM-2 is the second generation of intelligent weighing controller under K-Tron.It adopts modular design,integrates high-speed microprocessor,high-precision A/D converter and advanced digital filtering algorithm.It can process weighing sensor signals in real time and accurately adjust the feeding motor speed or valve opening through PID control algorithm to ensure stable material flow.Its core advantages include:

High-precision measurement:The resolution can reach 1:100,000,meeting the microgram weighing requirements.

Fast response:The sampling frequency is≥100 times/second,which is suitable for high-speed production lines.

Strong anti-interference ability:Effectively suppress the influence of vibration and electromagnetic interference on weighing signals.

Flexible communication:Supports multiple fieldbus protocols,which is convenient for integration with PLC,DCS,and SCADA systems.

2.Core functions

High-precision weighing control:

Real-time acquisition of weighing sensor signals,elimination of noise interference through digital filtering algorithm,and output of stable and accurate weight values.

Support single-point or multi-point calibration to adapt to different ranges and accuracy requirements.

Flow control and regulation:

According to the set flow value,the PID control algorithm automatically adjusts the feeding motor speed or valve opening to achieve constant flow or variable flow control.

Support batch feeding mode,preset target weight,and automatically complete the whole process of feeding,metering,and stopping.

Multi-parameter monitoring and display:

Real-time display of key parameters such as current weight,instantaneous flow,cumulative flow,and running time.

Support trend chart drawing to facilitate analysis of flow fluctuations.

Fault diagnosis and protection:

Detect abnormal conditions such as sensor disconnection,overload,underload,motor failure,etc.,and alarm through LED indicators or communication interfaces.

Provide historical fault records,support fault code query,and quickly locate the root cause of the problem.

Communication and data interaction:

Standard interface:RS-232/RS-485 serial port,support Modbus RTU protocol.

Optional interfaces:Ethernet(Modbus TCP),Profibus-DP,DeviceNet,CANopen(expansion modules are required).

Remote monitoring:Parameter setting,status display,data recording and other functions are realized through the host computer software.

Operation interface and programming:

Local operation panel:integrated LCD display and buttons,supports multi-language interfaces such as Chinese/English,and can perform parameter modification,mode switching,and calibration operations.

Programming flexibility:supports custom control logic and adapts to complex process flows.

3.Technical specifications(example,the actual product shall prevail)

Parameter Details

Product type Intelligent weighing controller

Model identification KCM-2

Input signal Weighing sensor:4-20mA or 0-10V(compatible with 350Ωor 700Ωbridge)

Output signal Control signal:4-20mA(drive inverter or motor controller)

Weighing range 0.1kg-10,000kg(customizable)

Resolution 1:100,000(typical value)

Sampling frequency≥100 times/second

Control mode PID control(supports independent adjustment of P,I,D parameters)

Communication interface RS-232/RS-485(standard);Ethernet,Profibus-DP,DeviceNet(optional)

Display and operation LCD display+button;support multi-language interface

Working power AC 85-265V,50/60Hz or DC 24V(need to confirm model configuration)

Environmental adaptability Working temperature:-10℃~+50℃;Storage temperature:-20℃~+70℃;Humidity≤85%RH(no condensation)

Protection level IP20(panel installation)or IP54(cabinet installation)

Certification standards CE,UL,FCC,RoHS

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101