描述

产品概述

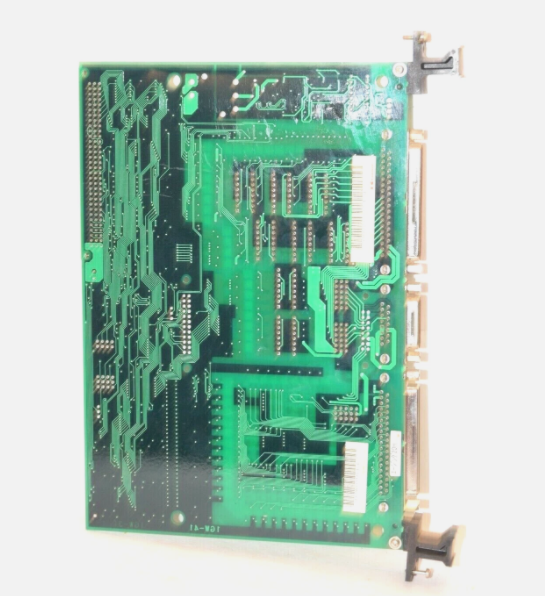

KAWASAKI 50999-2145R10是川崎(KAWASAKI)机器人系统中的核心控制板,属于工业自动化领域的重要组件。其设计目标为支持高精度运动控制、多协议通信及复杂逻辑处理,广泛应用于智能制造、工业机器人、核电设备等领域。

技术参数

控制能力

I/O扩展:支持过上千点数字量和模拟量控制,满足大规模工业设备的信号接入需求。

存储器容量:集成工作存储空间达几十MB,并支持外置存储卡扩展,满足复杂程序和数据存储需求。

非易失存储器:可选配置,确保数据持久化存储。

环境适应性

温度范围:0°C至60°C(符合IEC 60068-2-1/2/14标准)。

湿度范围:5%至95%(无凝露,符合IEC 60068-2-30标准)。

抗振动与冲击:

振动:10–500 Hz条件下2 g(IEC 60068-2-6标准)。

冲击:工作冲击30 g(IEC 60068-2-27标准)。

认证与安全

符合多项工业安全标准(如IEC 60068系列),适用于高可靠性场景。

在核电应用中具备耐辐照特性,支持极端环境下的稳定运行。

核心功能特点

工业自动化控制

支持多轴运动控制,适用于机器人关节驱动、伺服系统协调等场景。

提供实时数据采集与处理能力,优化生产效率和产品质量。

通信与扩展性

集成多协议通信接口(如Modbus、EtherCAT),兼容工业网络环境。

支持模块化扩展,可连接传感器、执行器及其他控制设备。

安全与防护

内置预测性维护功能,通过运营智能工具减少设备故障风险。

防护设计符合工业安全规范,保护知识产权及品牌形象。

核电领域适配

在核电站中用于应急救灾、事故处理及设备维修,满足高安全性需求。

Product Overview

KAWASAKI 50999-2145R10 is the core control board in the KAWASAKI robot system and is an important component in the field of industrial automation.Its design goal is to support high-precision motion control,multi-protocol communication and complex logic processing,and is widely used in fields such as intelligent manufacturing,industrial robots,and nuclear power equipment.

Technical parameters

Control capability

I/O expansion:supports digital and analog control over thousands of points,meeting the signal access needs of large-scale industrial equipment.

Memory capacity:The integrated working storage space reaches tens of MB and supports external memory card expansion to meet complex program and data storage needs.

Nonvolatile memory:Optional configuration to ensure persistent data storage.

Environmental adaptability

Temperature range:0°C to 60°C(compliant with IEC 60068-2-1/2/14 standard).

Humidity range:5%to 95%(no condensation,comply with IEC 60068-2-30).

Vibration and shock resistance:

Vibration:2 g at 10–500 Hz(IEC 60068-2-6 standard).

Impact:Working impact 30 g(IEC 60068-2-27 standard).

Certification and security

Comply with a number of industrial safety standards(such as IEC 60068 series),suitable for high reliability scenarios.

It has radiation resistance characteristics in nuclear power applications and supports stable operation in extreme environments.

Core functional features

Industrial automation control

Supports multi-axis motion control,suitable for robot joint drive,servo system coordination and other scenarios.

Provide real-time data acquisition and processing capabilities,optimize production efficiency and product quality.

Communication and scalability

Integrated multi-protocol communication interfaces(such as Modbus,EtherCAT),compatible with industrial network environments.

Supports modular expansion,and can connect sensors,actuators and other control devices.

Safety and protection

Built-in predictive maintenance features to reduce the risk of equipment failure through operational smart tools.

The protective design complies with industrial safety regulations and protects intellectual property rights and brand image.

Adaptation in the nuclear power field

It is used in nuclear power plants for emergency disaster relief,accident handling and equipment maintenance to meet high safety needs.