描述

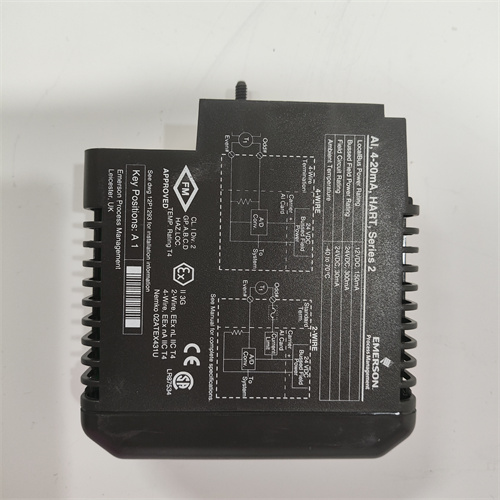

KJ4110X1-BA1是艾默生(Emerson)旗下的一款工业控制模块,以下为其详细产品信息:

一、核心功能

控制功能

可编程逻辑控制:作为高性能PLC(可编程逻辑控制器),该模块支持梯形图、布尔助记符、功能模块图等多种编程语言,可实现复杂逻辑控制、顺序控制及过程控制,适用于工业自动化系统中的核心控制任务。

输入输出扩展能力:模块具备灵活的输入输出配置,可根据实际需求扩展数字量/模拟量接口,适配不同工业场景下的信号采集与设备控制需求。

通信功能

多协议支持:内置多种通信接口(如RS232/485端口),兼容Modbus、PROFIBUS等主流工业通信协议,可与DCS、SCADA等系统无缝集成,实现数据交互与远程监控。

网络化集成:支持以太网通信,满足工业物联网(IIoT)需求,便于构建分布式控制系统。

二、技术特性

电气参数

电源规格:输入电源为24 VDC(1 A),现场电源支持4 A,满足工业现场供电需求。

硬件设计:模块重量约1.3 kg,采用紧凑型结构,便于安装于工业机柜中。

可靠性与环境适应性

工业级防护:具备高抗干扰能力和宽温工作范围(具体参数需参考官方文档),适应化工、电力、制造等领域的恶劣环境。

冗余与自检:支持冗余电源输入,内置自检功能,可实时监测模块状态,确保系统稳定运行。

三、应用领域

过程自动化

典型场景:广泛应用于化工生产线、石油精炼、水处理等流程工业,实现工艺参数的实时监测与控制。

离散制造

典型场景:适用于汽车制造、机械加工等领域的生产线控制,通过精确的逻辑控制提升生产效率与设备利用率。

能源管理

典型场景:在发电厂、变电站等场景中,模块可集成于能源管理系统中,实现设备状态监控与能效优化。

KJ4110X1-BA1 is an industrial control module under Emerson.The following is its detailed product information:

1.Core functions

Control function

Programmable logic control:As a high-performance PLC(programmable logic controller),the module supports multiple programming languagessuch as ladder diagrams,Boolean mnemonics,and function block diagrams.It can realize complex logic control,sequential control,and process control,and is suitable for core control tasks in industrial automation systems.

Input and output expansion capabilities:The module has flexible input and output configurations,and can expand digital/analog interfaces according to actual needs to adapt to signal acquisition and equipment control requirements in different industrial scenarios.

Communication function

Multi-protocol support:Built-in multiple communication interfaces(such as RS232/485 ports),compatible with mainstream industrial communication protocols such as Modbus and PROFIBUS,can be seamlessly integrated with DCS,SCADA and other systems to achieve data interaction and remote monitoring.

Network integration:Supports Ethernet communication,meets the needs of Industrial Internet of Things(IIoT),and facilitates the construction of distributed control systems.

2.Technical characteristics

Electrical parameters

Power supply specifications:The input power is 24 VDC(1 A),and the field power supply supports 4 A,which meets the power supply requirements of industrial sites.

Hardware design:The module weighs about 1.3 kg and adopts a compact structure,which is easy to install in industrial cabinets.

Reliability and environmental adaptability

Industrial-grade protection:It has high anti-interference ability and a wide temperature operating range(specific parameters need to refer to official documents),and is suitable for harsh environments in chemical,electric power,manufacturing and other fields.

Redundancy and self-test:It supports redundant power input and has a built-in self-test function,which can monitor the module status in real time to ensure stable operation of the system.

3.Application fields

Process automation

Typical scenarios:It is widely used in process industries such as chemical production lines,petroleum refining,and water treatment to achieve real-time monitoring and control of process parameters.

Discrete manufacturing

Typical scenarios:It is suitable for production line control in the fields of automobile manufacturing,mechanical processing,etc.,and improves production efficiency and equipment utilization through precise logic control.

Energy management

Typical scenarios:In power plants,substations and other scenarios,the module can be integrated into the energy management system to achieve equipment status monitoring and energy efficiency optimization.