描述

产品概述

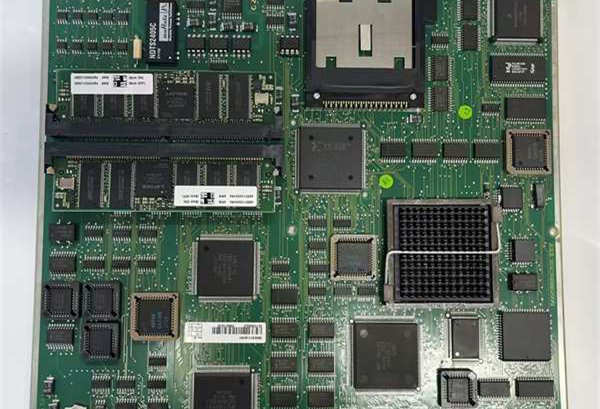

KNIEL CP15.6311-052-02是一款工业控制电源模块,属于KNIEL公司(德国)的电源产品线。该模块专为工业自动化系统设计,支持PLC(可编程逻辑控制器)的供电与信号处理,适用于高可靠性、高精度的工业场景,如机械制造、电力监控、化工过程控制等。

技术参数与功能特点

核心功能

电源供电:为PLC系统提供稳定直流电源,支持多路输出(具体电压和电流需参考型号变体)。

信号处理:可能集成模拟量或数字量信号调理功能,用于工业传感器信号的采集与传输。

模块化设计:支持19英寸机架安装,兼容KNIEL其他电源模块扩展。

可靠性与安全性

防静电保护:检修时需使用防静电装置,避免元件损坏。

冗余设计:部分型号支持冗余供电,确保系统连续运行。

过压/过流保护:内置保护电路,防止电源故障导致设备损坏。

环境适应性

工作温度:-20°C至60°C(具体范围需参考型号)。

防护等级:开放式设计,需避免灰尘和湿气侵入。

检修与维护规范

检修前准备

需准备专用工具(如防静电螺丝刀、数字电压表)。

检修前需与调度和操作工确认,挂检修牌并断开总电源。

拆装流程

步骤:

将CPU方式选择开关从“运行”切换至“停”状态。

关闭PLC总电源及各模块电源。

拆卸电源线并记录线号,移除电源机架。

旋转模板下方螺丝,拆卸CPU主板及I/O板。

安装:按相反顺序重新组装,确保连接稳固。

技术要求

电压测量:使用精度为1%的数字电压表。

模块操作:RAM模块需在断电状态下插拔,避免数据丢失。

静电防护:拆装时远离静电源,轻拿轻放模板。

应用场景

工业自动化

为PLC系统提供稳定电源,支持顺序控制、PID调节等功能。

过程控制

在化工、电力行业中集成信号调节器,实现长距离温差热电偶信号传输。

安全与集成

支持危险区域(如ATEX、UL Class 1 Div 2)的电源解决方案,满足国际安全标准。

PFTL101B 3BSE004185R1 2.0KN

PFTL101B 3BSE004185R1 2.0KN

Product Overview

KNIEL CP15.6311-052-02 is an industrial control power supply module and belongs to the power supply product line of KNIEL(Germany).This module is specially designed for industrial automation systems and supports power supply and signal processing of PLC(programmable logic controller).It is suitable for high reliability and high precision industrial scenarios,such as mechanical manufacturing,power monitoring,chemical process control,etc.

Technical parameters and functional characteristics

Core functions

Power supply:Provides stable DC power supply to the PLC system and supports multiple outputs(specific voltage and current require reference model variants).

Signal processing:It may integrate analog or digital signal conditioning functions for the acquisition and transmission of industrial sensor signals.

Modular design:Supports 19-inch rack mount,compatible with other KNIEL power module extensions.

Reliability and security

Anti-static protection:Anti-static devices are required during maintenance to avoid damage to components.

Redundant design:Some models support redundant power supply to ensure continuous operation of the system.

Overvoltage/overcurrent protection:Built-in protection circuit to prevent power failure from causing damage to equipment.

Environmental adaptability

Operating temperature:-20°C to 60°C(specific range requires reference model).

Protection level:Open design,to avoid intrusion of dust and moisture.

Maintenance and maintenance specifications

Preparation before maintenance

Special tools(such as anti-static screwdrivers,digital voltmeters)are required.

Before maintenance,you must confirm with the dispatcher and operator,mount the maintenance sign and disconnect the main power supply.

Disassembly and assembly process

step:

Switch the CPU mode selection switch from”Run”to”Stop”state.

Turn off the PLC main power supply and the power supply of each module.

Remove the power cord and record the cable number and remove the power rack.

Rotate the screws below the template to remove the CPU motherboard and I/O board.

Installation:Reassemble in reverse order to ensure a secure connection.

Technical requirements

Voltage measurement:Use a digital voltmeter with 1%accuracy.

Module operation:The RAM module needs to be plugged and unplugged in a power-off state to avoid data loss.

Electrostatic protection:Stay away from the static power supply when disassembling and assembly,and gently place the template.

Application scenarios

Industrial automation

Provides stable power supply to the PLC system,supports sequential control,PID adjustment and other functions.

Process control

Integrate signal regulators in the chemical and power industries to realize long-distance temperature difference thermocouple signal transmission.

Security and integration

Power solutions that support hazardous areas(such as ATEX,UL Class 1 Div 2)to meet international safety standards.