描述

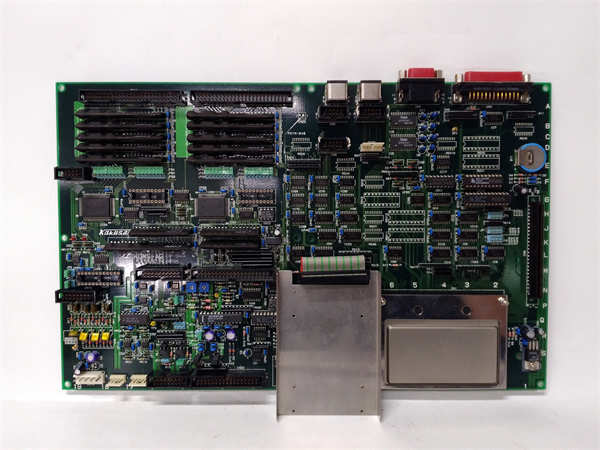

KOKUSAI CXP-544A KOMS-A2是一款多功能工业自动化控制模块,广泛应用于数据采集、信号处理、控制逻辑执行等领域。以下是其核心功能与技术特点的综合解析:

一、核心功能定位

数据采集与处理

支持多个模拟输入通道,可采集和测量来自传感器、信号源的高速模拟信号(如振动、温度、压力等),采样速率高且分辨率精确,适用于工业环境下的实时监控。

集成噪声抑制与滤波功能,通过算法优化减少干扰,确保数据准确性。

传感器接口

专为EPRO PR6423/003-030轴振动传感器设计,提供精密连接器和屏蔽设计,符合UL、CE等工业安全认证,适用于风电、电力、制造等严苛场景。

支持多类型传感器(温度、湿度、压力等),可扩展至多个通道,满足复杂监测需求。

控制与通信

作为CPU模块或主控板,负责执行控制逻辑,支持数据报和全局数据(GD)通信协议,实现与PLC、DCS等系统的高效交互。

提供RS-485、以太网等标准接口,兼容Modbus、PROFINET等工业协议,支持分布式系统架构。

二、技术特点

高性能处理能力

基于模块化设计,采用多核处理器,支持高速布尔逻辑运算与复杂算法处理,适用于运动控制、过程优化等实时性要求高的场景。

可靠性与安全性

内置24V DC防短路电源,保护无源触点输入;端子模块采用颜色编码和精密连接器,降低误操作风险。

通过工业环境测试,支持宽温(-30℃至65℃)和高湿度(20%-80%)运行。

灵活性与扩展性

支持远程I/O扩展,可集成至风电变电站SCADA系统、半导体制造设备等大型系统中,满足不同规模项目的部署需求。

三、应用场景

工业自动化

用于风电场监控(如风机状态监测)、火电厂辅助设备控制,实现冗余环网通信与数据同步。

能源管理

集成于变频器控制系统,优化水泵、电机的能耗,实现恒压供水等节能应用。

智能制造

应用于半导体制造中的温度控制系统,确保工艺参数稳定性;支持机器人柔性制造中的运动控制。

环境监测

用于空气质量、水质等参数的实时采集,配合物联网平台实现远程分析。

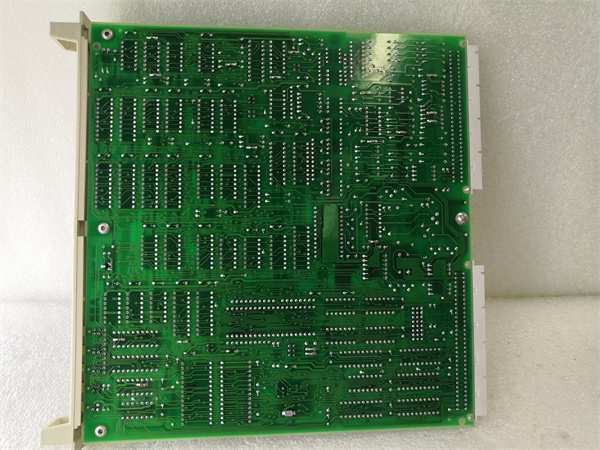

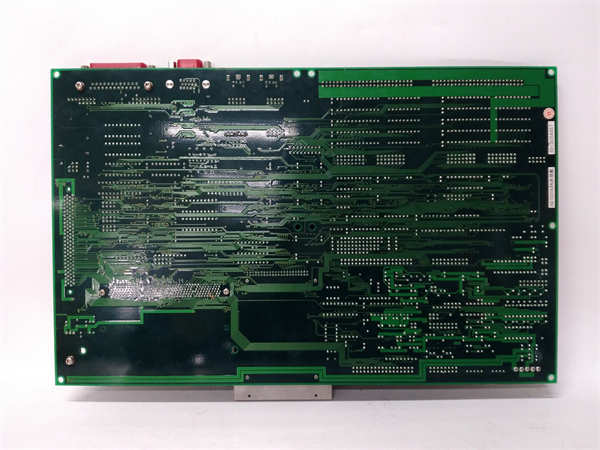

KOMS-A2 CXP-544A

KOMS-A2 CXP-544A

KOKUSAI CXP-544A KOMS-A2 is a multifunctional industrial automation control module,which is widely used in data acquisition,signal processing,control logic execution and other fields.The following is a comprehensive analysis of its core functions and technical features:

1.Core Function Positioning

Data Acquisition and Processing

Supports multiple analog input channels,can collect and measure high-speed analog signals(such as vibration,temperature,pressure,etc.)from sensors and signal sources,with high sampling rate and precise resolution,suitable for real-time monitoring in industrial environments.

Integrated noise suppression and filtering functions,reduce interference through algorithm optimization to ensure data accuracy.

Sensor Interface

Designed for EPRO PR6423/003-030 shaft vibration sensor,provides precision connector and shielding design,complies with UL,CE and other industrial safety certifications,suitable for harsh scenarios such as wind power,power,manufacturing,etc.

Supports multiple types of sensors(temperature,humidity,pressure,etc.),can be expanded to multiple channels to meet complex monitoring needs.

Control and Communication

As a CPU module or main control board,it is responsible for executing control logic,supporting datagram and global data(GD)communication protocols,and realizing efficient interaction with PLC,DCS and other systems.

It provides standard interfaces such as RS-485 and Ethernet,is compatible with industrial protocols such as Modbus and PROFINET,and supports distributed system architecture.

2.Technical Features

High-performance processing capability

Based on modular design,it adopts multi-core processors,supports high-speed Boolean logic operations and complex algorithm processing,and is suitable for scenarios with high real-time requirements such as motion control and process optimization.

Reliability and safety

Built-in 24V DC short-circuit-proof power supply to protect passive contact input;terminal modules use color coding and precision connectors to reduce the risk of misoperation.

Through industrial environment testing,it supports wide temperature(-30℃to 65℃)and high humidity(20%-80%)operation.

Flexibility and scalability

Supports remote I/O expansion and can be integrated into large systems such as wind power substation SCADA system and semiconductor manufacturing equipment to meet the deployment needs of projects of different sizes.

3.Application scenarios

Industrial automation

Used for wind farm monitoring(such as wind turbine status monitoring),auxiliary equipment control of thermal power plants,and redundant ring network communication and data synchronization.

Energy management

Integrated in the inverter control system to optimize the energy consumption of water pumps and motors,and realize energy-saving applications such as constant pressure water supply.

Intelligent manufacturing

Applied to temperature control systems in semiconductor manufacturing to ensure the stability of process parameters;support motion control in flexible manufacturing of robots.

Environmental monitoring

Used for real-time collection of parameters such as air quality and water quality,and remote analysis with the Internet of Things platform.