描述

LLASERGAS 12944-E是一款基于可调谐二极管激光吸收光谱技术(TDLAS)的高精度气体分析仪,专为复杂环境中的气体检测设计。以下是其核心功能与技术特点的综合解析:

一、技术原理与核心优势

TDLAS技术原理

利用半导体激光器的窄线宽和波长可调谐特性,通过扫描气体分子的特征吸收谱线,结合比尔-朗伯定律(Beer-Lambert Law),实现单组分气体的高灵敏度检测。

采用波长调制谐波检测,通过高频正弦调制激光频率,利用锁相放大器提取二次谐波信号,有效抑制噪声干扰。

核心性能指标

检测灵敏度:可达ppb(十亿分之一)级,适用于痕量气体分析。

响应速度:毫秒级响应,支持动态气体浓度跟踪。

抗干扰能力:选择性吸收特定气体谱线,避免背景气体交叉干扰。

二、硬件配置与功能模块

激光光源

量子级联激光器(QCL):覆盖中红外波段(如4.56μm、9.68μm),输出功率高(>100mW),波长调谐范围广(>100nm),适用于NH3、N2O、CH4等气体检测。

分布式反馈激光器(DFB):近红外波段(如1512nm),单纵模输出,稳定性优异。

检测系统

长光程吸收池:采用5-20米光程设计,结合中空光纤或简波结构,提升灵敏度并减少样品量需求。

中红外探测器:如碲镉汞(MCT)探测器,覆盖2-15μm波段,低温制冷(-30°C)以降低热噪声。

控制模块

集成数字激光驱动、锁相放大器和温控单元,支持软件远程调节激光电流、温度及调制参数。

支持压电执行器快速调整激光频率,响应时间<1ms,适用于长距离开放路径检测(如OPLAS技术)。

三、应用场景

工业过程控制

监测反应器中的NH3、CO、CH4等气体浓度,优化燃烧效率与产品质量。

钢铁、化工行业高温环境下的VOCs、SO2等排放分析。

环境监测

垃圾填埋场甲烷(CH4)泄漏检测,满足EPA方法21的低检出限(0.5ppm)要求。

大气中N2O、HCHO等温室气体的连续监测。

安全防护

石油天然气行业管道巡检,非接触式检测甲烷浓度,避免爆炸风险。

矿井、隧道等密闭空间有毒气体(如CO、H2S)预警。

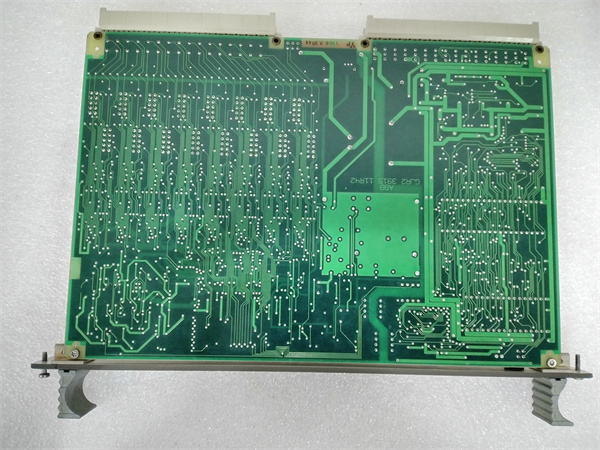

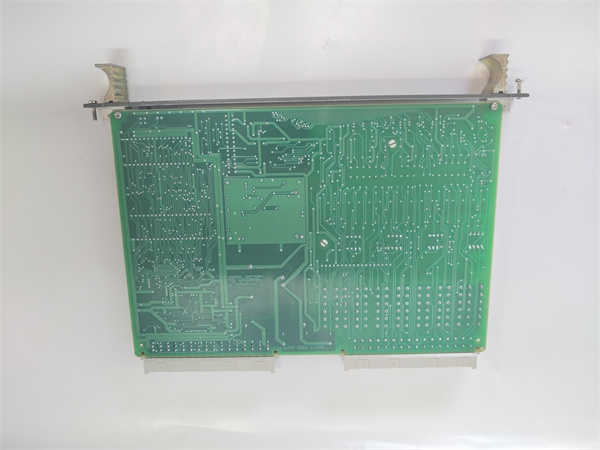

B5LA HENF327886R0001

B5LA HENF327886R0001

LLASERGAS 12944-E is a high-precision gas analyzer based on tunable diode laser absorption spectroscopy(TDLAS),designed for gas detection in complex environments.The following is a comprehensive analysis of its core functions and technical features:

I.Technical principles and core advantages

TDLAS technical principle

Using the narrow line width and wavelength tunable characteristics of semiconductor lasers,by scanning the characteristic absorption lines of gas molecules,combined with the Beer-Lambert Law,high-sensitivity detection of single-component gas is achieved.

Using wavelength modulation harmonic detection,the laser frequency is modulated by high-frequency sinusoidal modulation,and the second harmonic signal is extracted by a phase-locked amplifier to effectively suppress noise interference.

Core performance indicators

Detection sensitivity:up to ppb(parts per billion)level,suitable for trace gas analysis.

Response speed:millisecond response,support dynamic gas concentration tracking.

Anti-interference ability:selective absorption of specific gas lines to avoid cross-interference of background gases.

2.Hardware configuration and functional modules

Laser source

Quantum cascade laser(QCL):covers mid-infrared band(such as 4.56μm,9.68μm),high output power(>100mW),wide wavelength tuning range(>100nm),suitable for NH3,N2O,CH4 and other gas detection.

Distributed feedback laser(DFB):near-infrared band(such as 1512nm),single longitudinal mode output,excellent stability.

Detection system

Long optical path absorption cell:adopts 5-20m optical path design,combined with hollow fiber or simple wave structure,to improve sensitivity and reduce sample volume requirements.

Mid-infrared detector:such as mercury cadmium telluride(MCT)detector,covering 2-15μm band,low temperature cooling(-30°C)to reduce thermal noise.

Control module

Integrated digital laser driver,phase-locked amplifier and temperature control unit,support software remote adjustment of laser current,temperature and modulation parameters.

Supports piezoelectric actuators to quickly adjust laser frequency,with a response time of<1ms,suitable for long-distance open path detection(such as OPLAS technology).

3.Application scenarios

Industrial process control

Monitor the concentration of gases such as NH3,CO,and CH4 in the reactor to optimize combustion efficiency and product quality.

Emission analysis of VOCs,SO2,etc.in high temperature environments in the steel and chemical industries.

Environmental monitoring

Landfill methane(CH4)leakage detection meets the low detection limit(0.5ppm)requirements of EPA Method 21.

Continuous monitoring of greenhouse gases such as N2O and HCHO in the atmosphere.

Safety protection

Pipeline inspection in the oil and gas industry,non-contact detection of methane concentration to avoid explosion risks.

Early warning of toxic gases(such as CO and H2S)in confined spaces such as mines and tunnels.