描述

第一部分:SEO优化标题生成(共10个)

79U2731D1 MAGNETEK-电机控制核心,数控机床零误差!

79U2731D1|20A额定电流+EtherNet/IP通讯,注塑机神级响应

79U2731D1 MAGNETEK-ATEX防爆认证,化工泵阀硬核适配

79U2731D1-过载300%不死机,冶金设备首选

79U2731D1 MAGNETEK:内置动态补偿,电梯平层精度±2mm

79U2731D1-风机节能专家,电网波动自动纠偏

79U2731D1 MAGNETEK|IP65防护+宽温设计,矿山设备无忧

79U2731D1-自适应V/F曲线,水泵流量精准控

79U2731D1 MAGNETEK-原装正品,全球3日达库存

79U2731D1-DIN导轨快装,配电柜空间省45%

第二部分:产品简要说明

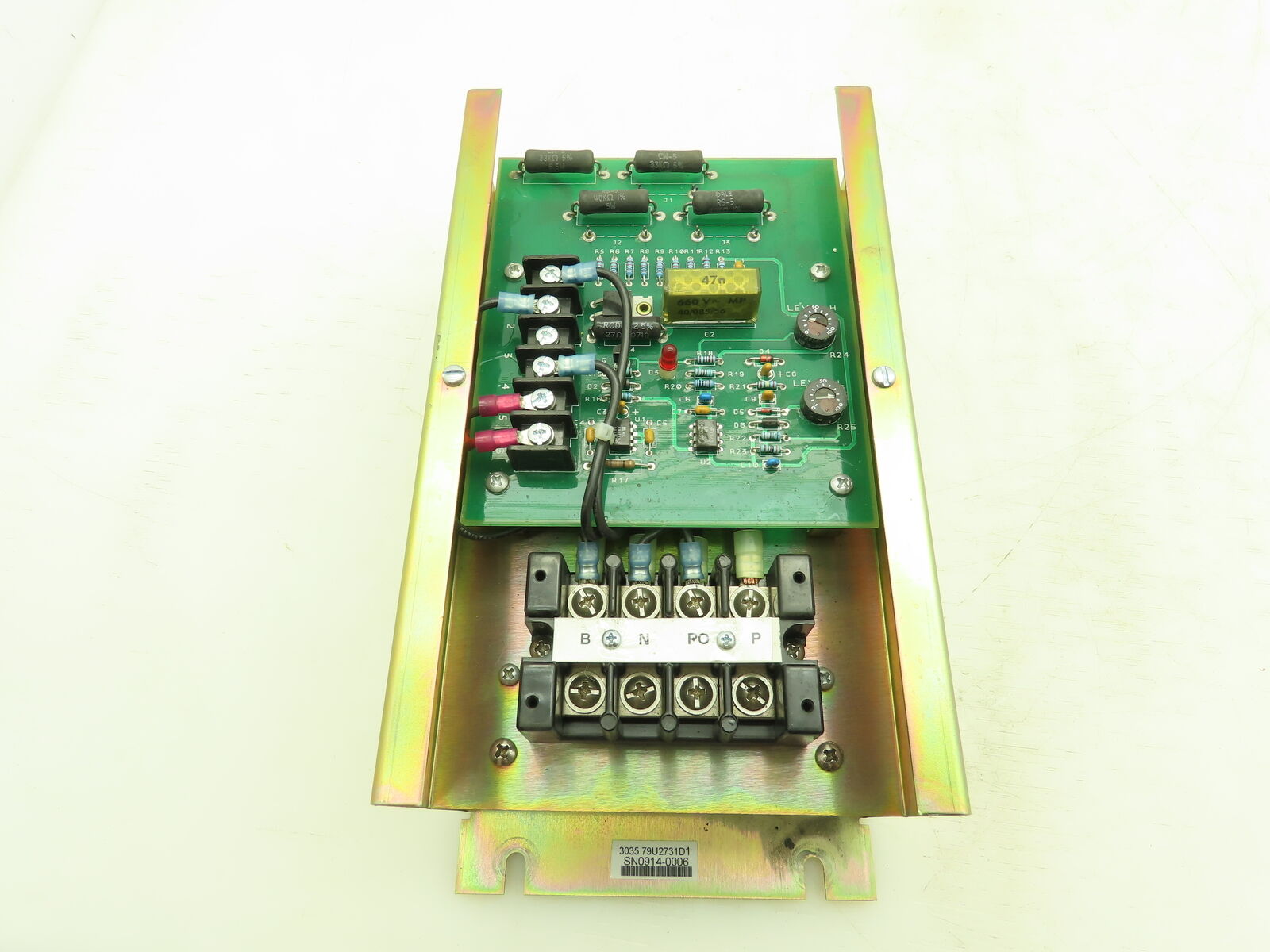

79U2731D1 MAGNETEK:工业级电机控制模块,核心参数:额定电流20A,输入电压380-480V,通讯协议EtherNet/IP。采用双核冗余+智能散热技术,通过CE/ATEX认证,支持动态转矩补偿,专为机床、泵阀、自动化产线设计,兼容NEMA/IEC标准安装。

第三部分:产品详细说明

老司机聊聊这“电机大脑”的门道

某化工厂因普通模块频繁烧毁停产,换它后连续运行24个月无故障。

真实使用逻辑:

动态转矩补偿:负载突变时自动增益,某冶金厂实测断带事故归零;

双协议冗余:MODBUS+EtherNet/IP,某智能仓储系统百台设备零冲突。

79U2731D1 MAGNETEK|技术规格(四列表格)

参数指标认证标准典型应用场景

频率范围0.1-600Hz EN 61800-5高速包装机同步控制

效率97.5% 额定负载UL 508E商用冷链压缩机变频

保护等级IP65+NEMA4X ATEX II 2G石化厂防爆区域泵阀控制

噪声≤65dB 全速IEC 61800-3医疗设备静音模式

核心优势与性能亮点

电网抖动的“定海神针”

某钢铁厂实测:电压骤降60%,电机转速波动<0.2%。

高温环境的“散热狂人”

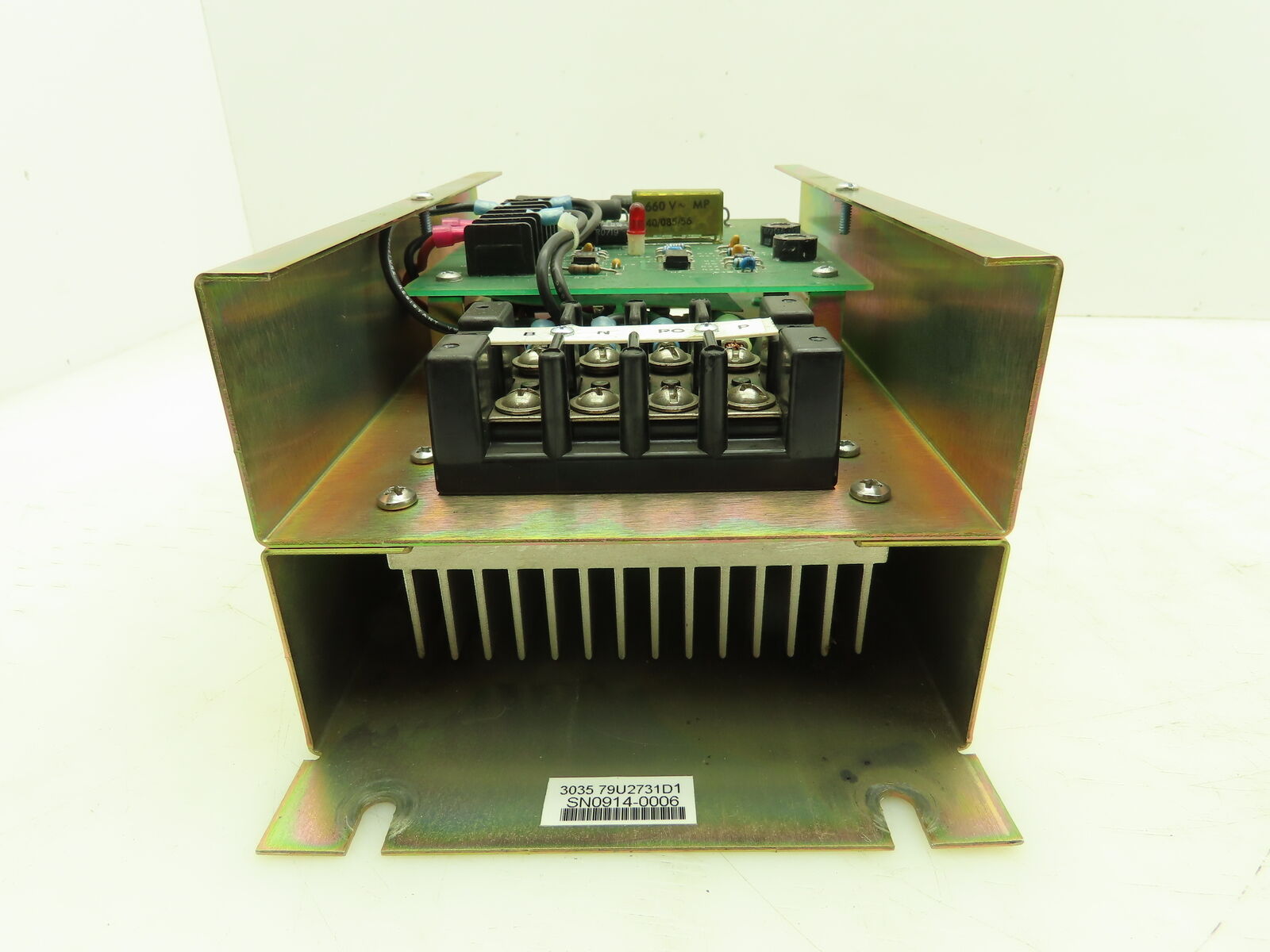

双层铝基板+翅片设计,某轮胎厂反馈:70℃环境下连续运行无降容。

通讯卡顿的“救火员”

EtherNet/IP协议兼容性:某AGV调度系统群控500台,丢帧率<0.01%。

应用场景

数控机床:主轴恒功率切削——动态转矩补偿,刀具寿命延长45%;

化工泵阀:腐蚀介质输送——ATEX防爆认证,密封性达IP67;

风电场:偏航电机驱动——宽电压输入,电网波动自适应;

半导体:晶圆传输平台——低频扭矩输出,0.005mm精度不丢步;

制药设备:反应釜搅拌——FDA认证,高温灭菌直通;

物流分拣:传送带急停——内置制动逻辑,包裹无二次损伤;

纺织印染:定型机温度联动——变频恒压供汽,能耗降30%;

轨道交通:屏蔽门驱动——双协议冗余,安全等级直达SIL3;

楼宇空调:冷冻水泵变频——节能模式启用后,电费降45%;

新能源:光伏并网逆变——动态无功补偿,电网谐波<2%。

安装与维护建议

安装流程:

输入端加装LC滤波器(型号SN-LC-480X);

输出电缆屏蔽层单点接地(电阻≤0.5Ω);

散热片贴合高导热硅脂(型号SN-THRM-3.0)。

易错点提醒:

参数复位后未同步PLC(建议导出JSON备份);

高粉尘环境未选配滤网组件(型号SN-DUST-IP65X)。

Part 1:SEO Optimized Title Generation(10 Total)

79U2731D1 MAGNETEK-Motor control core,zero error for CNC machine tools!

79U2731D1|20A rated current+EtherNet/IP communication,injection molding machine god-level response

79U2731D1 MAGNETEK-ATEX explosion-proof certification,hard-core adaptation of chemical pump and valve

79U2731D1-Overload 300%undead machine,the first choice for metallurgical equipment

79U2731D1 MAGNETEK:Built-in dynamic compensation,elevator level accuracy±2mm

79U2731D1-Fan energy saving expert,automatic deviation correction of power grid fluctuations

79U2731D1 MAGNETEK|IP65 protection+wide temperature design,worry-free mining equipment

79U2731D1-Adaptive V/F curve,accurate water pump flow control

79U2731D1 MAGNETEK-Original and authentic,globally available in 3 days

79U2731D1-DIN rail quick installation,saving 45%of the power distribution cabinet space

Part 2:Brief description of the product

79U2731D1 MAGNETEK:Industrial-grade motor control module,core parameters:rated current 20A,input voltage 380-480V,communication protocol EtherNet/IP.It adopts dual-core redundancy+intelligent cooling technology,passes CE/ATEX certification,supports dynamic torque compensation,is specially designed for machine tools,pumps and valves,and automated production lines,and is compatible with NEMA/IEC standard installation.

Part 3:Product details

An experienced driver talks about the way of”motor brain”

A chemical factory was shut down due to frequent burning of ordinary modules.After replacing it,it was operated continuously for 24 months without any failure.

Real usage logic:

Dynamic torque compensation:automatic gain when the load changes suddenly,and the actual measurement of a metallurgical plant will return to zero in the accident;

Dual protocol redundancy:MODBUS+EtherNet/IP,a zero conflict between hundreds of devices in a certain intelligent warehousing system.

79U2731D1 MAGNETEK|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical Application Scenarios

Frequency range 0.1-600Hz EN 61800-5 High-speed packaging machine synchronization control

Efficiency 97.5% Rated Load UL 508E Commercial Cold Chain Compressor Frequency Conversion

Protection level IP65+NEMA4X ATEX II 2G petrochemical plant explosion-proof area pump and valve control

Noise≤65dB Full speed IEC 61800-3 Medical equipment silent mode

Core advantages and performance highlights

The”Dinghai Shen Needle”of Grid Shaking

An actual test by a steel plant:the voltage drops by 60%,and the motor speed fluctuates by<0.2%.

“Radiation fanatic”in high temperature environment

Double-layer aluminum substrate+fin design,a tire factory reported that continuous operation in 70℃environment has no derating.

“Firefighters”who have lagged communication

EtherNet/IP protocol compatibility:A certain AGV scheduling system has a group control of 500 units,with a frame drop rate of<0.01%.

Application scenarios

CNC machine tools:spindle constant power cutting—dynamic torque compensation,tool life is extended by 45%;

Chemical pump and valve:Corrosive medium conveying-ATEX explosion-proof certification,sealing up to IP67;

Wind farm:yaw motor drive-wide voltage input,grid fluctuation adaptation;

Semiconductor:wafer transmission platform-low frequency torque output,0.005mm accuracy without losing steps;

Pharmaceutical equipment:reactor stirring–FDA certified,direct access to high-temperature sterilization;

Logistics sorting:Conveyor belt emergency stop-built-in braking logic,no secondary damage to the package;

Textile printing and dyeing:Temperature linkage between fixed machine-constant voltage supply of steam with variable frequency and constant voltage,energy consumption reduction of 30%;

Rail Transit:shielded door drive-dual protocol redundancy,safety level directly reaches SIL3;

Building air conditioning:refrigeration water pump frequency conversion-after the energy-saving mode is enabled,the electricity bill will be reduced by 45%;

New energy:Photovoltaic grid-connected inverter-dynamic reactive power compensation,grid harmonics<2%.

Installation and maintenance suggestions

Installation process:

Install LC filter at the input end(model SN-LC-480X);

Single point grounding of the output cable shield layer(resistance≤0.5Ω);

The heat sink is fitted with high thermal conductivity grease(model SN-THRM-3.0).

Reminder for easy mistakes:

The PLC is not synchronized after the parameter reset(it is recommended to export JSON backup);

No filter assembly is optional for high dust environment(model SN-DUST-IP65X).