描述

产品简要说明

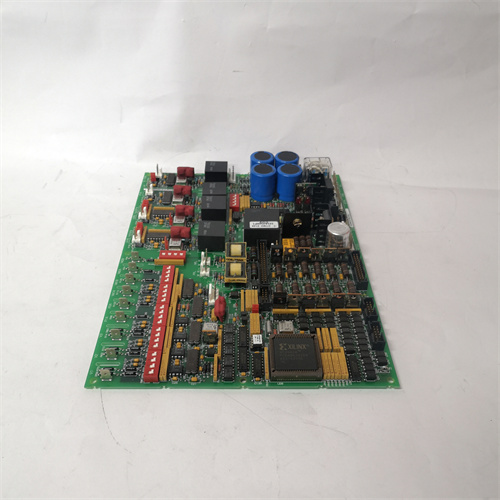

MAGNETEK DS325是一款面向工业自动化领域的智能驱动控制器,核心特性包括:

多轴协同控制:支持4轴同步运动控制,兼容伺服电机与步进电机

高精度定位:定位精度达±0.01mm,适用于精密加工场景

开放式架构:支持Python/C++二次开发,适配主流工业协议

产品详细说明

1.核心技术架构

运动控制算法:

采用PID+前馈控制策略,动态响应时间≤5ms

支持电子齿轮比、凸轮曲线等复杂运动曲线生成

通信协议支持:

内置EtherCAT、CANopen双主站协议栈

支持OPC UA over TCP/IP工业物联网协议

2.硬件设计亮点

模块化扩展:

提供64位ARM Cortex-R5处理器,主频达1GHz

支持热插拔I/O模块(数字量、模拟量、编码器输入)

环境适应性:

工作温度范围-30℃至70℃

防护等级IP67(可选配IP69K版本)

技术规格:MAGNETEK DS325

参数项规格描述

控制轴数4轴独立控制(支持级联扩展至16轴)

定位精度±0.01mm(重复定位精度±0.005mm)

通信接口2×EtherCAT、1×CANopen、1×RS-485

电源输入12-48V DC(支持冗余供电)

存储容量1GB DDR4 RAM+16GB eMMC Flash

核心价值与性能亮点

1.柔性制造适配

案例:在电子贴片机中实现0.2mm级贴装精度,良品率提升至99.97%

2.智能诊断系统

优势:内置振动频谱分析功能,可预测轴承磨损周期

3.快速集成开发

功能:提供LabVIEW/Python开发包,缩短系统部署周期40%

应对挑战,创造价值

1.复杂运动轨迹控制

方案:在3D打印设备中,通过插补算法实现连续S型加减速控制

2.多协议兼容场景

应用:支持EtherCAT与CANopen混合组网,适配老旧设备升级需求

Product brief description

MAGNETEK DS325 is an intelligent drive controller for the field of industrial automation,with core features including:

Multi-axis collaborative control:supports 4-axis synchronous motion control,compatible with servo motors and stepper motors

High-precision positioning:Positioning accuracy up to±0.01mm,suitable for precision machining scenarios

Open architecture:Support Python/C++secondary development,adapt to mainstream industrial protocols

Product details

1.Core technology architecture

Motion control algorithm:

Adopt PID+feedforward control strategy,dynamic response time≤5ms

Supports the generation of complex motion curves such as electronic gear ratio and cam curve

Communication protocol support:

Built-in dual master protocol stack of EtherCAT and CANopen

Support OPC UA over TCP/IP Industrial Internet of Things protocol

2.Highlights of hardware design

Modular extension:

Provides 64-bit ARM Cortex-R5 processor with a main frequency of up to 1GHz

Supports hot-swap I/O modules(digital,analog,encoder input)

Environmental adaptability:

Operating temperature range-30℃to 70℃

Protection level IP67(optional IP69K version)

Technical Specifications:MAGNETEK DS325

Parameters Specification Description

Number of control axes:4-axis independent control(supports cascade expansion to 16 axes)

Positioning accuracy±0.01mm(repeat positioning accuracy±0.005mm)

Communication interface 2×EtherCAT,1×CANopen,1×RS-485

Power input 12-48V DC(supports redundant power supply)

Storage capacity 1GB DDR4 RAM+16GB eMMC Flash

Core Valuesand Performance Highlights

1.Flexible manufacturing adaptation

Case:Achieve 0.2mm level mounting accuracy in electronic patch machines,and the yield rate is increased to 99.97%.

2.Intelligent diagnostic system

Advantages:Built-in vibration spectrum analysis function,can predict bearing wear cycles

3.Rapid integrated development

Function:Provide LabVIEW/Python development package to shorten the system deployment cycle by 40%

Respond to challenges and create value

1.Complex motion trajectory control

Solution:In 3D printing equipment,continuous S-type acceleration and deceleration control is realized through interpolation algorithm

2.Multi-protocol compatible scenarios

Application:Supports hybrid networking between EtherCAT and CANopen to adapt to the upgrade requirements of old equipment