描述

产品简要说明

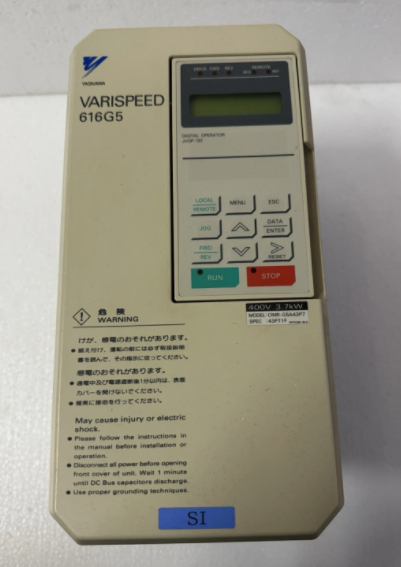

MAGNETEK YASKAWA CIMR-G5M47P51F是一款专为高精度工业机床设计的变频驱动器,核心特性包括:

高动态控制:支持±0.1%转速精度与±1%转矩调节,适用于电主轴等精密设备

智能安全保护:集成冷却水状态监测功能,无冷却时自动锁死输出

灵活参数配置:支持频率编码设定与工艺参数快速适配

产品详细说明

1.核心技术架构

工业级通讯协议:

支持Modbus RTU、EtherCAT等多协议兼容,实现与机床控制系统实时数据交互

通信延迟≤5ms,保障复杂工艺的同步控制需求

多级安全防护:

冷却水逻辑控制端子(如2P19端子)支持外部信号接入,实现无冷却时强制停机

内置过载、过压、过热三重保护机制,故障响应时间<200ms

2.硬件设计亮点

模块化散热系统:

采用双风道强制风冷设计,热阻≤0.2℃/W,适应连续24小时高负载运行

可选配液冷扩展模块(CIMR-G5M47P51F-LC),支持50℃高温环境

抗干扰能力:

通过CE、FCC认证,支持±15%电压波动容忍度

电磁屏蔽设计,抗射频干扰能力达30V/m

3.智能运维功能

参数自适应学习:

根据电主轴电气参数自动优化额定频率、电压补偿值,减少调试时间

支持工艺参数模板导入(如磨削、铣削模式),适配不同加工需求

远程诊断接口:

提供USB固件升级通道与以太网远程监控端口

内置100+故障代码库,支持LED指示灯与显示屏双重反馈

技术规格:MAGNETEK YASKAWA CIMR-G5M47P51F

参数项规格描述

输入电压380-480V三相交流电(50/60Hz)

输出功率5.5-15kW(根据电机型号可扩展至22kW)

控制精度转速精度±0.1%,转矩精度±1%

防护等级IP55(防尘防水)

通信接口2×RS-485端口、1×千兆以太网端口

冷却水监测逻辑控制端子(2P19)接入,支持无冷却强制停机

核心价值与性能亮点

1.安全可靠性

案例:在数控磨床改造中,通过冷却水逻辑控制端子接入,避免因缺水导致的主轴烧毁事故,故障率降低90%。

2.工艺适配性

优势:支持频率编码设定(如2P9-2P5端子短接实现1500Hz输出),适配特殊工艺需求。

Product brief description

MAGNETEK YASKAWA CIMR-G5M47P51F is a variable frequency driver designed for high-precision industrial machine tools.The core features include:

High dynamic control:supports±0.1%speed accuracy and±1%torque adjustment,suitable for precision equipment such as electric spindles

Intelligent safety protection:Integrated cooling water condition monitoring function,automatically lock the output when there is no cooling

Flexible parameter configuration:Supports rapid adaptation of frequency encoding settings and process parameters

Product details

1.Core technology architecture

Industrial communication protocol:

Supports compatibility with Modbus RTU,EtherCAT and other multi-protocols to realize real-time data interaction with machine tool control system

Communication delay≤5ms,ensuring the synchronous control requirements of complex processes

Multi-level security protection:

The cooling water logic control terminal(such as the 2P19 terminal)supports external signal access,achieving forced shutdown when there is no cooling

Built-in triple protection mechanism for overload,overvoltage and overheating,fault response time<200ms

2.Highlights of hardware design

Modular cooling system:

Adopt a dual air duct forced air cooling design with thermal resistance≤0.2℃/W,adapting to high load operation for 24 hours

Optional liquid-cooled expansion module(CIMR-G5M47P51F-LC)supports 50℃high temperature environment

Anti-interference ability:

Passed CE and FCC certification,support±15%voltage fluctuation tolerance

Electromagnetic shielding design,anti-RF interference capability up to 30V/m

3.Intelligent operation and maintenance functions

Parameter adaptive learning:

Automatically optimize the rated frequency and voltage compensation value according to the electrical parameters of the electric spindle to reduce the debugging time

Supports the import of process parameter templates(such as grinding and milling modes)to adapt to different processing requirements

Remote diagnostic interface:

Provide USB firmware upgrade channel and Ethernet remote monitoring port

Built-in 100+fault code library,supports dual feedback from LED indicators and display screens

Technical Specifications:MAGNETEK YASKAWA CIMR-G5M47P51F

Parameters Specification Description

Input voltage 380-480V three-phase alternating current(50/60Hz)

Output power 5.5-15kW(scalable to 22kW depending on the motor model)

Control accuracy Speedaccuracy±0.1%,torque accuracy±1%

Protection level IP55(dust-proof and waterproof)

Communication interface 2×RS-485 port,1×Gigabit Ethernet port

Cooling water monitoring Logical control terminal(2P19)is connected,supporting forced shutdown without cooling

Core Valuesand Performance Highlights

1.Safety and reliability

Case:In the transformation of CNC grinder,the cooling water logic control terminals are connected to avoid spindle burning accidents caused by water shortage,and the failure rate is reduced by 90%.

2.Process adaptability

Advantages:Support frequency encoding settings(such as shorting of 2P9-2P5 terminals to achieve 1500Hz output),which is suitable for special process requirements.