描述

产品简要说明

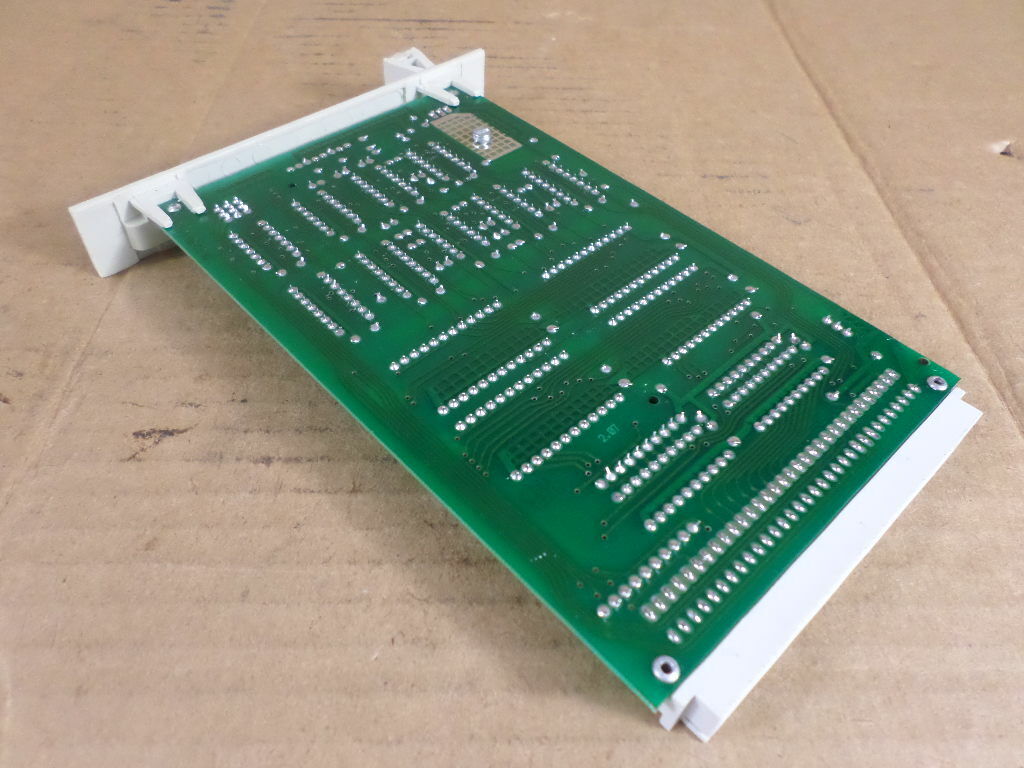

Marposs 6320610614与4K16组成马波斯(MARPOSS)新一代无线测头系统,支持多轴同步测量与智能加工校准,集成温度补偿算法,适用于高动态数控机床环境,显著提升复杂轮廓加工的一致性。

产品详细说明

技术架构解析

6320610614主控测头

多自由度感知:六轴加速度计(量程±10g,带宽0-5kHz)。

环境自适应:内置温度传感器(补偿范围-30℃~+100℃)。

4K16无线通信模块

工业级稳定性:支持5GHz高频段传输(抗干扰等级IP65)。

低延迟同步:多测头组网时钟同步误差<0.1ms。

智能加工校准流程

动态刀具补偿:实时采集刀尖磨损数据并修正NC代码(补偿精度±0.01mm)。

工艺参数优化:通过切削力-振动频谱分析推荐spindle speed调整策略。

产品概述:Marposs 6320610614|4K16

该系统通过无线测头-主控算法-云端分析的三级架构,解决了高速铣削中“刀具微观磨损实时监测”与“多轴联动误差解耦”的技术瓶颈,尤其适用于五轴联动加工中心与复合材料成型设备。

技术规格:Marposs 6320610614|4K16

模块性能参数

测头本体重量120g(轻量化镁合金)/防护等级IP68

通信模块传输速率100Mbps/工作距离30m(金属屏蔽环境下)

校准精度重复定位误差<±0.5μm(标准偏差)

Product brief description

Marposs 6320610614 and 4K16 form the new generation of MARPOSS wireless probe system,which supports multi-axis synchronous measurement and intelligent machining calibration,integrates temperature compensation algorithms,and is suitable for high-dynamic CNC machine tool environments,significantly improving the consistency of complex contour processing.

Product details

Technical architecture analysis

6320610614 Main control probe

Multi-degree of freedom perception:six-axis accelerometer(range±10g,bandwidth 0-5kHz).

Environmental adaptation:built-in temperature sensor(compensation range-30℃~+100℃).

4K16 wireless communication module

Industrial-grade stability:Supports 5GHz high-frequency band transmission(anti-interference level IP65).

Low-latency synchronization:Multi-probe network clock synchronization error<0.1ms.

Intelligent machining calibration process

Dynamic tool compensation:collect tip wear data in real time and correct NC code(compensation accuracy±0.01mm).

Process parameter optimization:Recommended spindle speed adjustment strategy through cutting force-vibration spectrum analysis.

Product Overview:Marposs 6320610614|4K16

Through the three-level architecture of wireless probe-main control algorithm-cloud analysis,the system solves the technical bottlenecks of”real-time monitoring of tool microscopic wear”and”decoupling of multi-axis linkage errors”in high-speed milling,and is especially suitable for five-axis linkage machining centers and composite material forming equipment.

Technical Specifications:Marposs 6320610614|4K16

Module Performance Parameters

Probe body Weight 120g(lightweight magnesium alloy)/Protection level IP68

Communication module Transmission rate 100Mbps/Working distance 30m(under metal shielding environment)

Calibration accuracy Repeat positioning error<±0.5μm(standard deviation)