描述

第一部分:SEO优化标题生成(共10个)

Marposs 683029830-高温轴承“退火卫士”,残余应力秒变历史!

Marposs 683029830|原装蓝宝石探针+RS422通信,纳米级形变终结者

Marposs 683029830-±0.002mm精度,航空叶片余量直接打脸人工卡尺

Marposs 683029830-IP69K高压防爆,发动机曲轴跳动零妥协

Marposs 683029830:风电齿轮“磨损先知”,齿面点蚀提前预警

Marposs 683029830-抗油污干扰王,半导体晶圆检测稳如狗

Marposs 683029830|智能产线AGV校准探头,定位偏移自动拉闸

Marposs 683029830-热插拔+冗余设计,夜班换产不瘫痪

Marposs 683029830:陶瓷刀具“崩刃侦探”,磨削粗糙度Ra0.01直出

Marposs 683029830-光纤传输+抗震结构,锂电池极片张力稳如泰山

第二部分:产品简要说明

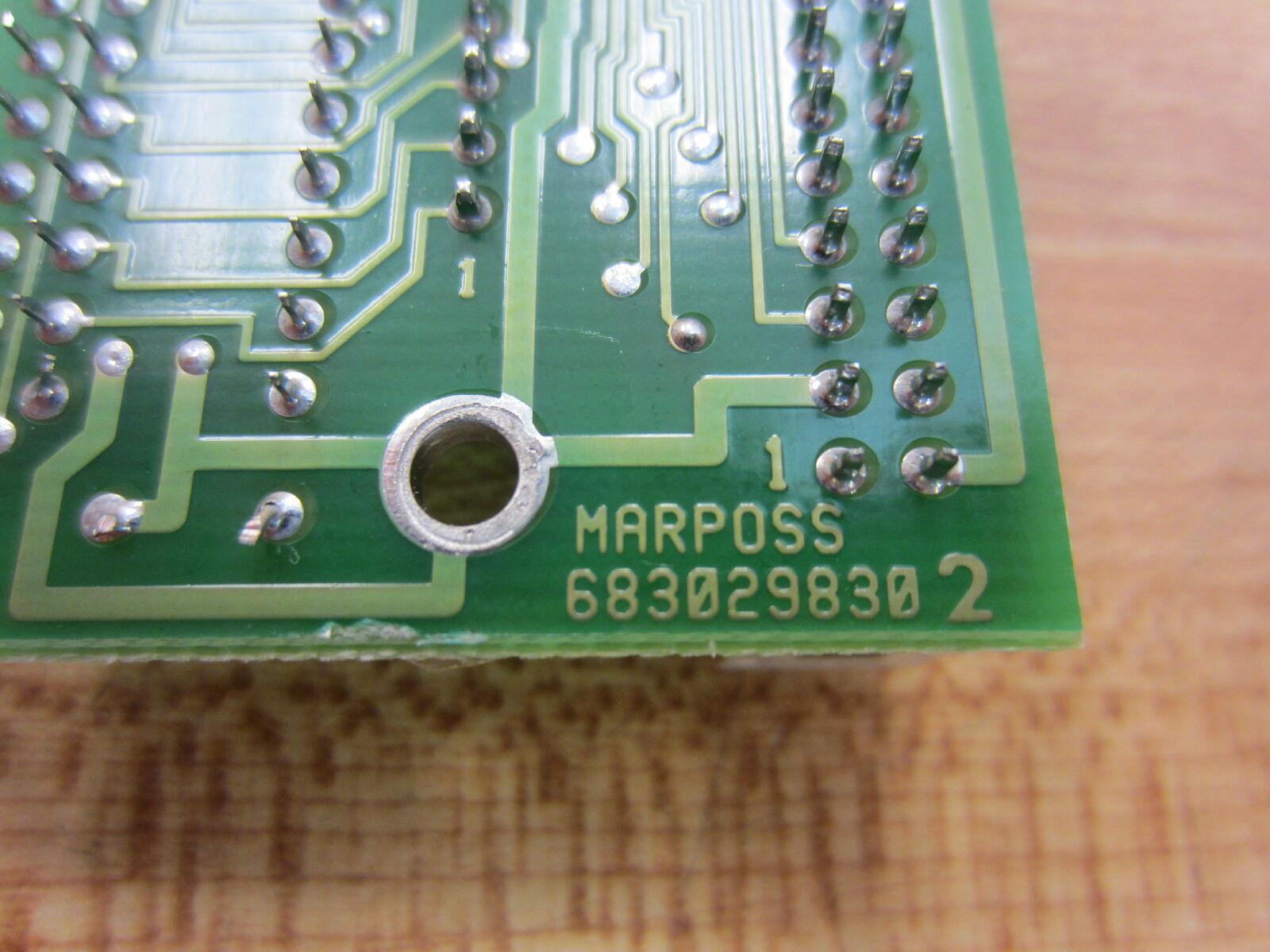

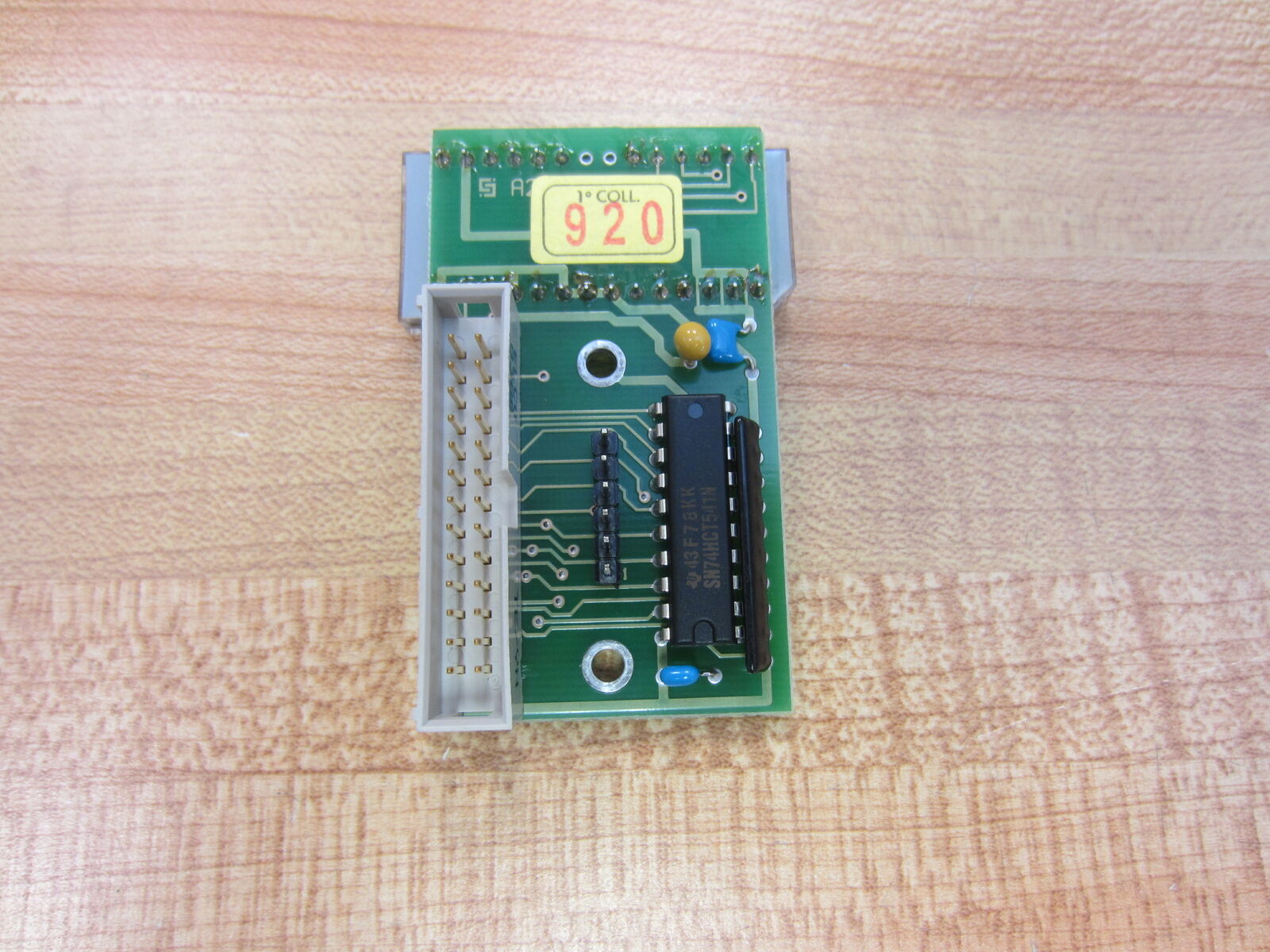

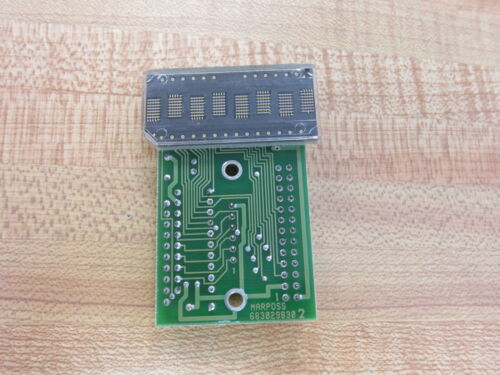

Marposs 683029830:高温环境接触式测头,专攻微米级残余应力监测。核心参数:量程0-0.5mm,精度±0.002mm,接口RS422。适用于航空、能源高温部件检测,通过蓝宝石探针+热膨胀补偿算法实现毫秒级响应,兼容KEYENCE IL-S系列、OMRON E2E光电传感器。

第三部分:产品详细说明

老司机聊聊这“火眼金睛”的门道

这对测头是Marposs给高温产线装的“应力CT”。某风电厂之前靠超声波抽检齿轮磨损,装上它后在线全检,月省拆卸成本80万,齿面点蚀预警提前48小时。

真实使用逻辑:

涡轮盘榫槽:热变形实时补偿,打磨时间砍半;

陶瓷轴承滚道:纳米级跳动量采集,异响投诉归零。

Marposs 683029830|技术规格(四列表格)

参数指标测试标准典型应用场景

工作温度200~800℃ISO 16063-41航空发动机叶片余量监测

防护等级IP69K EN 60529高压清洗环境检测

通信协议RS422/Modbus ASCII IEC 61158火电厂转子跳动监控

响应频率120kHz VDI/VDE 3513高速锻造模具磨损诊断

核心优势与性能亮点

蓝宝石探针的“金刚不坏”

某钢厂部署后,耐氧化+抗飞溅,轧辊形变监测五年零故障。

热膨胀补偿的“温度魔法”

某航天厂用它穿透800℃烟气监测涡轮盘,信号漂移<0.5%FS,废品率<0.02%。

冗余电源的“保命设计”

某核电厂配置双电源模块,主泵轴承检测系统连续运行365天。

应用场景

火电厂:汽轮机转子——热膨胀量实时补偿,轴振超标预警;

航空航天:涡轮叶片榫槽——高温余量纳米级判定,试车爆裂风险清零;

钢铁冶金:轧辊磨耗——氧化皮穿透检测,板厚公差缩至±0.01mm;

半导体:晶圆退火——应力分布云图生成,良率飙升;

医疗器械:义齿支架——高温变形量检测,3D打印缺陷归零;

消费电子:LED芯片——焊料回流应力分析,虚焊投诉停;

军工:导弹尾喷管——热疲劳裂纹预警,飞行稳定性拉满;

化工:反应釜密封——热变形量监控,泄漏事故月降90%;

轨道交通:高铁刹车盘——高温磨损量实时反馈,制动距离缩短20%;

科研实验:超导材料——临界温度形变捕捉,论文数据硬控。

安装与维护建议

安装流程:

探针与工件间距设为0.3倍触发行程(防热膨胀干涉);

信号线穿陶瓷铠装管(型号SCT-CERA-PRO);

上电后执行“热漂移自校准”(菜单AUTO_CAL_HT)。

易错点提醒:

高温场景未选钨基座(型号CB-9800);

强电磁环境未启用光纤耦合器(推荐OPT-5000)

Part 1:SEO Optimized Title Generation(10 Total)

Marposs 683029830-“Annealing Guard”of high-temperature bearings,residual stress turns into history in seconds!

Marposs 683029830|Original sapphire probe+RS422 communication,nano-scale deformation terminator

Marposs 683029830-±0.002mm accuracy,aviation blade margin directly slap the artificial caliper in the face

Marposs 683029830-IP69K high-voltage explosion-proof,engine crankshaft jump zero compromise

Marposs 683029830:Wind power gear”wear prophet”,early warning of tooth pitting corrosion

Marposs 683029830-Anti-oil and pollution interference king,semiconductor wafer detection is as stable as a dog

Marposs 683029830|Intelligent production line AGV calibration probe,automatic pulling of positioning offset

Marposs 683029830-Hot-swap+redundant design,night shift replacement without paralysis

Marposs 683029830:Ceramic tool”Crack Detective”,grinding roughness Ra0.01 straight out

Marposs 683029830-fiber transmission+earthquake resistance structure,lithium battery electrode tension as stable as Taishan

Part 2:Brief description of the product

Marposs 683029830:High temperature environmental contact probe specializing in micron-level residual stress monitoring.Core parameters:range 0-0.5mm,accuracy±0.002mm,interface RS422.Suitable for high-temperature components detection of aviation and energy,it realizes millisecond response through sapphire probe+thermal expansion compensation algorithm,and is compatible with KEYENCE IL-S series and OMRON E2E photoelectric sensors.

Part 3:Product details

An experienced driver talks about the way of”fire eyes”

This pair of probes is the”stress CT”installed by Marposs for high-temperature production lines.A wind power plant used ultrasonic sampling to inspect the wear of the gears.After installing it,it was fully inspected online,saving 800,000 yuan in dismantling costs and 48 hours in advance of the pitting warning of tooth surface.

Real usage logic:

Turbine disc tongue and groove:real-time compensation for thermal deformation,grinding time is cut in half;

Ceramic bearing raceway:Nanoscale jump volume collection,abnormal noise complaints are reset to zero.

Marposs 683029830|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Working temperature 200~800℃ISO 16063-41 Monitoring of aircraft engine blade margin

Protection level IP69K EN 60529 High pressure cleaning environment detection

Communication protocol RS422/Modbus ASCII IEC 61158 Rotor jump monitoring in thermal power plant

Response frequency 120kHz VDI/VDE 3513 High-speed forging mold wear diagnosis

Core advantages and performance highlights

The”Kiamond Indestructible”of Sapphire Probe

After the deployment of a steel mill,it is resistant to oxidation+splash resistance,and roll deformation monitoring is zero faults for five years.

The”temperature magic”of thermal expansion compensation

A space factory used it to penetrate 800℃flue gas to monitor the turbine disk,with signal drifting<0.5%FS and scrap rate<0.02%.

“Life-saving design”of redundant power supplies

A nuclear power plant is equipped with dual power modules,and the main pump bearing detection system operates continuously for 365 days.

Application scenarios

Thermal power plant:turbine rotor-real-time compensation for thermal expansion,early warning of shaft vibration exceeding standard;

Aerospace:Turbine blade tongue and groove-judgment of high temperature margin nanoscale,clearing the risk of bursting in the test run;

Iron and Steel Metallurgy:Roller wear–Oxide scale penetration detection,plate thickness tolerance shrinks to±0.01mm;

Semiconductor:wafer annealing-stress distribution cloud map generation,yield soaring;

Medical devices:denture bracket-high-temperature deformation detection,3D printing defects are reset to zero;

Consumer Electronics:LED chips—Solder reflux stress analysis,false solder complaints and suspension;

Military industry:missile tail nozzle-thermal fatigue crack warning,flight stability is full;

Chemical Industry:Reactor sealing-monitoring of thermal deformation,leakage accidents drop by 90%per month;

Rail Transit:High-speed rail brake discs-real-time feedback on high-temperature wear,shortening the braking distance by 20%;

Scientific research experiments:superconducting materials-critical temperature deformation capture,hard control of paper data.

Installation and maintenance suggestions

Installation process:

Set the distance between the probe and the workpiece to 0.3 times the trigger stroke(proof of heat expansion interference);

Signal wire through ceramic armored tube(model SCT-CERA-PRO);

After power-on,perform”Hot Drift Self-Calibration”(menu AUTO_CAL_HT).

Reminder for easy mistakes:

Tungsten base is not selected for high temperature scenarios(model CB-9800);

Fiber optic coupler is not enabled for strong electromagnetic environment(OPT-5000 is recommended).