描述

MECS EXT-1产品详情

一、基本信息

品牌:MECS(Monsanto Enviro-Chem Systems,现属于杜邦公司旗下,专注于硫回收、尾气处理及工业环保技术领域)。

型号:EXT-1

类型:硫回收工艺扩展模块或专用分析/控制单元(具体功能需结合应用场景,可能为Claus硫回收工艺的扩展组件或分析仪模块)。

用途:广泛应用于石油炼制、天然气加工、煤化工等行业,用于硫磺回收装置(SRU)的工艺优化、尾气处理或关键参数监测(如H₂S/SO₂比值控制)。

二、技术规格与功能

1.核心功能

硫回收工艺扩展:

可能为Claus工艺的尾气处理模块(如SCOT工艺的预处理单元),用于降低尾气中SO₂和硫化物排放。

支持热反应段或催化反应段的参数调节(如温度、气体流量、催化剂活性监测)。

分析监测功能(若为分析仪模块):

实时测量关键气体成分(如H₂S、SO₂、COS浓度),精度通常为±1%FS(满量程)。

支持4~20 mA模拟输出或数字通信(如Modbus RTU),与DCS系统集成。

2.性能参数

测量范围(若为分析仪):

H₂S:0~1000 ppm(可扩展至更高量程)。

SO₂:0~500 ppm。

响应时间:≤10秒(T90,达到90%信号稳定值)。

工作环境:

温度:-20℃至+60℃(分析仪模块需防爆设计)。

压力:0.1~1 MPa(耐压设计,适应工艺管路压力)。

防护等级:IP65(防尘防水,适用于户外或工业现场)。

3.电气与通信

供电要求:24 VDC(±15%),功耗≤50 W(含加热与显示功能)。

通信接口:

模拟输出:2路4~20 mA(可配置为H₂S/SO₂浓度或比值)。

数字通信:RS-485(Modbus RTU),支持多点组网。

报警输出:2路继电器(NO/NC可选,触点容量250 VAC/5 A)。

4.机械设计

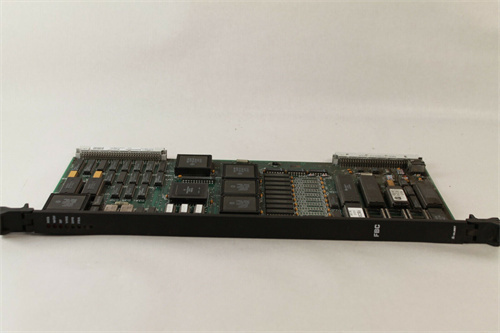

安装方式:壁挂式或机架式(19英寸标准),适配控制室或现场防爆柜。

材质:外壳为316L不锈钢(耐腐蚀),传感器窗口为蓝宝石或氟化钙(抗硫化物腐蚀)。

尺寸:约300×200×150 mm(具体因型号而异)。

三、产品优势

高精度与可靠性

采用电化学或紫外光谱分析技术(若为分析仪),抗干扰能力强,长期稳定性优于±2%FS/年。

关键部件(如传感器、阀体)通过ATEX/IECEx防爆认证,适用于Zone 1/2危险区域。

智能化与易用性

内置自诊断功能(如传感器寿命、校准提醒),减少维护成本。

支持HMI触摸屏(可选),实时显示趋势图、报警历史与操作日志。

工艺兼容性

专为硫回收装置设计,兼容主流工艺包(如Shell Claus、Thiopaq)。

可扩展模块化设计,支持多通道并行监测(如同时分析H₂S、SO₂、O₂)。

MECS EXT-1 Product Details

I.Basic Information

Brand:MECS(Monsanto Enviro-Chem Systems,now a subsidiary of DuPont,focusing on sulfur recovery,tail gas treatment and industrial environmental protection technology).

Model:EXT-1

Type:Sulfur recovery process extension module or dedicated analysis/control unit(specific functions need to be combined with application scenarios,which may be an extension component or analyzer module of the Claus sulfur recovery process).

Application:Widely used in petroleum refining,natural gas processing,coal chemical industry and other industries for process optimization,tail gas treatment or key parameter monitoring(such as H₂S/SO₂ratio control)of sulfur recovery unit(SRU).

II.Technical specifications and functions

1.Core functions

Sulfur recovery process extension:

It may be a tail gas treatment module of the Claus process(such as the pretreatment unit of the SCOT process)to reduce SO₂and sulfide emissions in the tail gas.

Support parameter adjustment of the thermal reaction section or catalytic reaction section(such as temperature,gas flow,catalyst activity monitoring).

Analysis and monitoring function(if it is an analyzer module):

Real-time measurement of key gas components(such as H₂S,SO₂,COS concentrations),with an accuracy of typically±1%FS(full scale).

Supports 4~20 mA analog output or digital communication(such as Modbus RTU),integrated with DCS system.

2.Performance parameters

Measurement range(if it is an analyzer):

H₂S:0~1000 ppm(can be expanded to a higher range).

SO₂:0~500 ppm.

Response time:≤10 seconds(T90,reaching 90%signal stability value).

Working environment:

Temperature:-20℃to+60℃(analyzer module requires explosion-proof design).

Pressure:0.1~1 MPa(pressure-resistant design,adapted to process pipeline pressure).

Protection level:IP65(dustproof and waterproof,suitable for outdoor or industrial sites).

3.Electrical and communication

Power supply requirements:24 VDC(±15%),power consumption≤50 W(including heating and display functions).

Communication interface:

Analog output:2 channels 4~20 mA(configurable as H₂S/SO₂concentration or ratio).

Digital communication:RS-485(Modbus RTU),supports multi-point networking.

Alarm output:2 channels relay(NO/NC optional,contact capacity 250 VAC/5 A).

4.Mechanical design

Installation method:wall-mounted or rack-mounted(19-inch standard),suitable for control room or on-site explosion-proof cabinet.

Material:The shell is 316L stainless steel(corrosion-resistant),and the sensor window is sapphire or calcium fluoride(anti-sulfide corrosion).

Dimensions:about 300×200×150 mm(depending on the model).

3.Product Advantages

High Precision and Reliability

Adopting electrochemical or UV spectroscopy analysis technology(if it is an analyzer),it has strong anti-interference ability and long-term stability better than±2%FS/year.

Key components(such as sensors and valve bodies)are ATEX/IECEx explosion-proof certified and suitable for Zone 1/2 hazardous areas.

Intelligence and Ease of Use

Built-in self-diagnostic functions(such as sensor life and calibration reminders)to reduce maintenance costs.

Support HMI touch screen(optional)to display trend charts,alarm history and operation logs in real time.

Process Compatibility

Designed for sulfur recovery units,compatible with mainstream process packages(such as Shell Claus,Thiopaq).

Scalable modular design supports multi-channel parallel monitoring(such as simultaneous analysis of H₂S,SO₂,O₂).