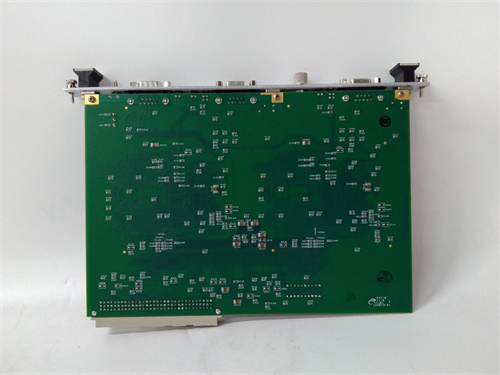

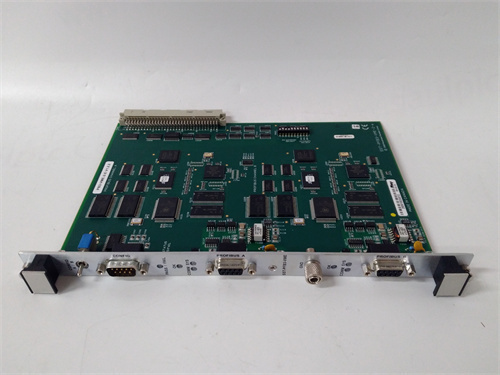

描述

MECS UTV-F2500HA是一款基于工业自动化控制技术的高性能PLC(可编程逻辑控制器)系统,广泛应用于石油化工、电力、冶金等复杂工业场景。以下是其核心功能与技术特点的综合解析:

一、系统架构与核心功能

整体式设计

采用整体式集成结构,支持控制室安装,便于集中管理与维护。

集成操作管理级、工程师站、数据网关等模块,可实现生产监控、参数配置、报警管理及人工干预操作。

硬件性能参数

工作电压:18.5至36Vdc,支持宽电压输入,适应复杂工业环境。

处理速度:50MHz,支持高速数据处理与实时响应,满足高动态工业控制需求。

存储容量:根据机型选择,小型机最大存储能力低于6KB,中型机可达64KB,大型机支持兆字节级扩展。

功能扩展性

支持模块化扩展,可连接各类传感器(如IFM反射光开关、Eltrotec光纤传感器)及执行机构(如Norgren电磁阀),构建完整自动化系统。

兼容主流工业协议(如Modbus、Profinet),便于与其他设备无缝集成。

二、技术优势

高可靠性

通过UL认证,防护等级高,适应-40℃至60℃工作温度及高湿度环境(5%-95%非冷凝)。

冗余设计支持故障自诊断与快速切换,降低停机风险。

智能控制特性

支持梯形逻辑、顺序控制及数据通信功能,可实现复杂工艺流程的自动化管理。

集成数据记录与趋势分析模块,便于生产优化与故障溯源。

工程易用性

配套STEP 7等组态软件,支持图形化编程与参数快速配置,降低开发周期。

提供标准化接口,便于第三方系统对接与二次开发。

三、应用场景

流程工业

化工生产中的温度、压力、液位控制,实现工艺参数的闭环调节与安全联锁。

电力系统

变电站自动化控制,包括断路器操作、保护逻辑执行及数据采集。

智能制造

柔性生产线的设备协同控制,支持快速切换生产模式与质量追溯。

MECS UTV-F2500HA is a high-performance PLC(Programmable Logic Controller)system based on industrial automation control technology,which is widely used in complex industrial scenarios such as petrochemical,electric power,and metallurgy.The following is a comprehensive analysis of its core functions and technical features:

1.System architecture and core functions

Integrated design

Adopts an integrated structure to support control room installation,which is convenient for centralized management and maintenance.

Integrated operation management level,engineer station,data gateway and other modules can realize production monitoring,parameter configuration,alarm management and manual intervention operations.

Hardware performance parameters

Working voltage:18.5 to 36Vdc,supports wide voltage input,and adapts to complex industrial environments.

Processing speed:50MHz,supports high-speed data processing and real-time response,and meets the needs of high-dynamic industrial control.

Storage capacity:Depending on the model selection,the maximum storage capacity of the minicomputer is less than 6KB,the medium-sized computer can reach 64KB,and the large computer supports megabyte-level expansion.

Functional scalability

Supports modular expansion,can connect various sensors(such as IFM reflective light switch,Eltrotec fiber optic sensor)and actuators(such as Norgren solenoid valve)to build a complete automation system.

Compatible with mainstream industrial protocols(such as Modbus,Profinet),it is easy to integrate with other devices seamlessly.

2.Technical advantages

High reliability

UL certified,high protection level,adaptable to-40℃to 60℃working temperature and high humidity environment(5%-95%non-condensing).

Redundant design supports fault self-diagnosis and fast switching to reduce the risk of downtime.

Intelligent control characteristics

Supports ladder logic,sequential control and data communication functions,which can realize the automated management of complex process flows.

Integrated data recording and trend analysis modules are convenient for production optimization and fault tracing.

Engineering usability

Supporting configuration software such as STEP 7,supporting graphical programming and rapid parameter configuration,reducing the development cycle.

Provides standardized interfaces to facilitate third-party system docking and secondary development.

3.Application scenarios

Process industry

Temperature,pressure,and liquid level control in chemical production to achieve closed-loop adjustment and safety interlocking of process parameters.

Power system

Substation automation control,including circuit breaker operation,protection logic execution,and data acquisition.

Intelligent manufacturing

Equipment collaborative control of flexible production lines,supporting rapid switching of production modes and quality traceability.