描述

产品简要说明

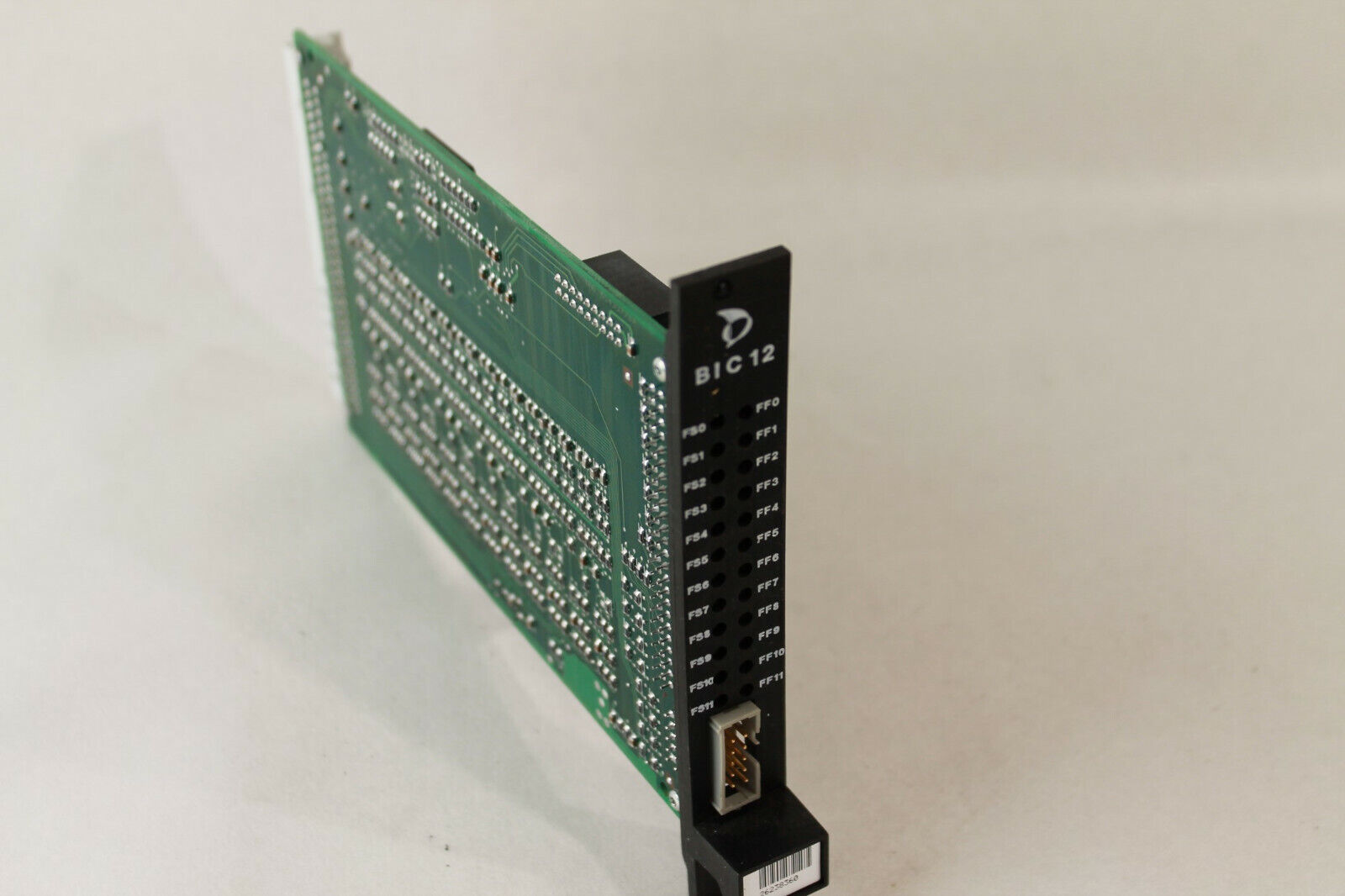

Metso D100226 BIC12是一款高性能工业数据采集模块,核心功能包括:

多通道输入:支持16路模拟量输入(4-20mA/0-10V)与16路数字量输入/输出

协议兼容性:内置Modbus RTU/TCP、Profibus DP双协议栈

工业级防护:IP67防护等级,耐受-40°C至70°C极端温度

抗干扰设计:电磁兼容性(EMC)符合IEC 61000-6-4标准

产品详细说明

1.技术架构与核心功能

信号处理单元:

模拟量输入:24位Σ-ΔADC,线性误差≤0.1%FS

隔离设计:每通道独立隔离(500Vrms),支持共模抑制比≥100dB

通信架构:

双总线冗余:主从双Profibus DP接口,故障自切换时间≤50ms

协议转换:支持Modbus RTU与OPC UA协议实时转换

智能诊断:

通道自检:每10秒自动检测信号完整性,异常报警阈值可配置

日志记录:存储10万条事件记录,支持SD卡导出

2.工业环境适配性

宽温运行:

低温补偿:内置温度传感器,自动补偿-40°C低温导致的信号漂移

高温防护:采用散热鳍片+导热硅胶设计,70°C环境下功耗降低20%

振动抗性:

机械加固:模块外壳通过MIL-STD-810G振动测试(3g加速度)

接线防护:抗震型弹簧端子,抗拉力≥50N

技术规格:Metso D100226 BIC12

参数项规格描述

通道配置16AI+16DI/DO(可扩展至32AI)

精度等级±0.1%FS(模拟量输入),±1bit(数字量)

通信接口2×Profibus DP(RS485)、1×Modbus TCP(RJ45)

防护等级IP67(防尘防水)

工作温度-40℃至70℃

电源输入24V DC(宽电压范围18-32V)

核心价值与性能亮点

1.双协议无缝切换

技术突破:采用硬件协议栈分离设计,Modbus与Profibus数据冲突率降低至0.01%

2.极端振动耐受

场景适配:在矿山皮带输送机振动环境下连续运行10万小时无故障(实测数据)

应对挑战,创造价值

1.多协议系统兼容性问题

技术突破:某钢铁厂部署BIC12后,实现PLC与DCS系统数据同步延迟≤20ms

2.高温环境信号衰减

场景案例:水泥厂回转窑监测系统使用BIC12,信号稳定性提升40%(对比传统模块)

Product brief description

Metso D100226 BIC12 is a high-performance industrial data acquisition module with core functions including:

Multi-channel input:Supports 16 analog inputs(4-20mA/0-10V)and 16 digital inputs/outputs

Protocol compatibility:Built-in Modbus RTU/TCP and Profibus DP dual protocol stacks

Industrial protection:IP67 protection rating,withstand extreme temperatures-40°C to 70°C

Anti-interference design:electromagnetic compatibility(EMC)complies with IEC 61000-6-4 standard

Product details

1.Technical architecture and core functions

Signal processing unit:

Analog input:24-bitΣ-ΔADC,linear error≤0.1%FS

Isolation design:independent isolation per channel(500Vrms),supports common mode rejection ratio≥100dB

Communication architecture:

Dual bus redundancy:Master-slave dual Profibus DP interface,fault self-switching time≤50ms

Protocol conversion:Supports real-time conversion of Modbus RTU and OPC UA protocols

Intelligent Diagnosis:

Channel self-test:Automatically detect signal integrity every 10 seconds,abnormal alarm threshold can be configured

Logging:Store 100,000 event records,supports SD card export

2.Industrial environment adaptability

Wide temperature operation:

Low temperature compensation:built-in temperature sensor,automatically compensates for signal drift caused by low temperature of-40°C

High temperature protection:adopts heat dissipation fins+thermal silicone design,reduces power consumption by 20%in 70°C environment

Vibration resistance:

Mechanical reinforcement:The module housing passes MIL-STD-810G vibration test(3g acceleration)

Wiring protection:shock-resistant spring terminal,tensile force≥50N

Technical Specifications:Metso D100226 BIC12

Parameters Specification Description

Channel configuration 16AI+16DI/DO(scalable to 32AI)

Accuracy level±0.1%FS(analog input),±1bit(digital)

Communication interface 2×Profibus DP(RS485),1×Modbus TCP(RJ45)

Protection level IP67(dust-proof and waterproof)

Operating temperature-40℃to 70℃

Power input 24V DC(wide voltage range 18-32V)

Core Valuesand Performance Highlights

1.Dual protocol seamless switching

Technical breakthrough:Using hardware protocol stack separation design,the data conflict rate between Modbus and Profibus is reduced to 0.01%

2.Extreme vibration tolerance

Scenario adaptation:continuous operation for 100,000 hours without faults(actual measurement data)

Respond to challenges and create value

1.Multi-protocol system compatibility issues

Technical breakthrough:After a steel plant deploys BIC12,the data synchronization delay of PLC and DCS system is≤20ms

2.High temperature environment signal attenuation

Scenario case:The rotary kiln monitoring system of cement plant uses BIC12,and the signal stability is improved by 40%(compared with traditional modules)