描述

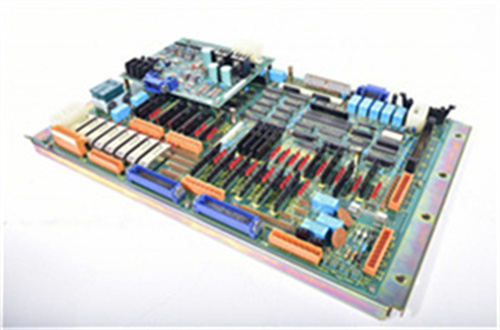

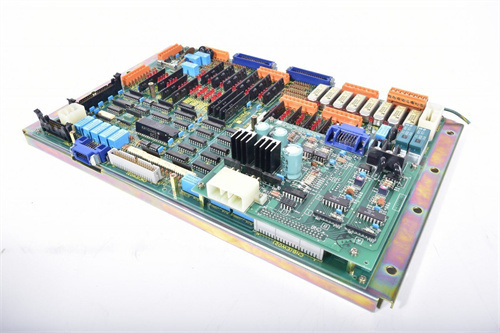

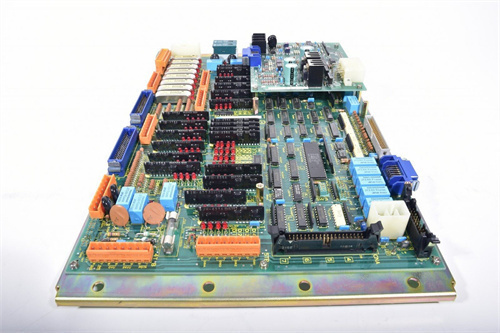

MINDMAN MCQV-11-32-610M产品简介

核心功能与定位

MCQV-11-32-610M是Mindman公司开发的针对用户特定PLC节点的工具套件,专为工业控制场景设计。其核心功能包括:

用户定制化支持:支持用户特定硬件部件的集成,通过链接用户自定义的C程序扩展功能,实现软件与硬件的无缝协同。

编程灵活性:基于IEC 61131-3标准,兼容图形化(KOP/FUB)和文本化(AWL/ST)编程语言,支持OpenPCS开发环境,适用于IBM兼容PC及MS-Windows 9x/ME/NT4.0系统。

分散控制能力:通过集成CApen功能,可作为智能、分散的控制节点,适用于输入/输出混合连接及顺序事件程序的实现。

关键技术参数

PLC芯片(PLC Chip164)

-封装形式:DIP40

-输入/输出配置:支持少量I/O控制任务,适合分布式信号处理。

-标准遵循:IEC 61131-3,兼容工业自动化领域主流编程规范。

系统兼容性

-操作系统:MS-Windows 9x/ME/NT4.0

-编程工具:OpenPCS软件,提供图形化与文本化编程界面。

质量与可靠性

-成色:全新

-质保期:1年

-适用范围:全国销售,适合工业现场部署。

典型应用场景

智能模块开发:作为硬件访问区的PLC核心部件,快速构建定制化控制模块。

网络化控制:分散处理进程信号,实现分布式工业网络节点的协同工作。

传统系统升级:通过扩展用户特定程序,提升原有控制系统的智能化水平。

MINDMAN MCQV-11-32-610M Product Introduction

Core Functions and Positioning

MCQV-11-32-610M is a tool kit developed by Mindman for user-specific PLC nodes,designed for industrial control scenarios.Its core functions include:

User customization support:supports the integration of user-specific hardware components,and achieves seamless collaboration between software and hardware by linking user-defined C program extension functions.

Programming flexibility:Based on IEC 61131-3 standard,compatible with graphical(KOP/FUB)and textual(AWL/ST)programming languages,supports OpenPCS development environment,and is suitable for IBM compatible PCs and MS-Windows 9x/ME/NT4.0 systems.

Distributed control capabilities:Through the integrated CApen function,it can be used as an intelligent,distributed control node,suitable for the implementation of input/output mixed connections and sequential event programs.

Key technical parameters

PLC chip(PLC Chip164)

-Package:DIP40

-Input/output configuration:supports a small number of I/O control tasks,suitable for distributed signal processing.

-Standard compliance:IEC 61131-3,compatible with mainstream programming specifications in the field of industrial automation.

System compatibility

-Operating system:MS-Windows 9x/ME/NT4.0

-Programming tool:OpenPCS software,providing graphical and textual programming interfaces.

Quality and reliability

-Condition:Brand new

-Warranty period:1 year

-Scope of application:nationwide sales,suitable for industrial field deployment.

Typical application scenarios

Intelligent module development:As the core component of the PLC in the hardware access area,quickly build customized control modules.

Networked control:Decentralized processing of process signals to achieve collaborative work of distributed industrial network nodes.

Traditional system upgrade:Improve the intelligence level of the original control system by expanding user-specific programs.