描述

MKS RPS AX7695是一款高性能远程等离子源,广泛应用于半导体制造、光伏、显示器等多个领域。以下是其核心产品特性与技术参数的综合概述:

一、核心参数与性能

基础参数

-频率:13.56 MHz

-功率:2 kW

-等离子体密度:>10^12 cm^-3

-等离子体均匀性:<5%

-尺寸:600 mm×400 mm×300 mm(标准版)/399 mm×348 mm×308 mm(集成版)

-重量:20 kg(标准版)/38.6 kg(集成版)

气体处理能力

-点火气体:100%O₂、Ar或90%O₂/10%N₂(可扩展其他气体)

-工艺气体:支持高达6.0 slm的O₂或O₂/N₂混合气流量

二、技术特点

高密度与均匀性

采用射频(RF)与微波技术,生成高密度、均匀分布的等离子体,适用于精密材料处理。

集成设计

将电源、匹配网络、等离子体腔体整合为紧凑单元,便于直接安装于工艺腔室,减少空间占用。

灵活性与兼容性

支持多种气体类型和工艺参数调节,适用于刻蚀、沉积、清洗等不同半导体制造流程。

可靠性与维护

-长寿命设计,适用于严苛工业环境;

-模块化结构,维护便捷,降低停机时间。

三、结构与工作原理

核心组件

-电源:提供高频能量,驱动等离子体生成;

-匹配网络:优化能量传输效率;

-等离子体腔体:通过电磁场激发气体形成等离子体,经出口传输至目标表面。

控制与通信

支持RS-232、DeviceNet、以太网等接口,兼容MKS TOOLweb®等控制系统,实现远程监控与智能联动。

四、应用领域

半导体制造

晶圆清洗、光刻胶去除、薄膜沉积等工艺。

光伏与显示器

玻璃镀膜、面板蚀刻等表面处理。

其他领域

生物医学器件改性、航空航天材料表面强化等。

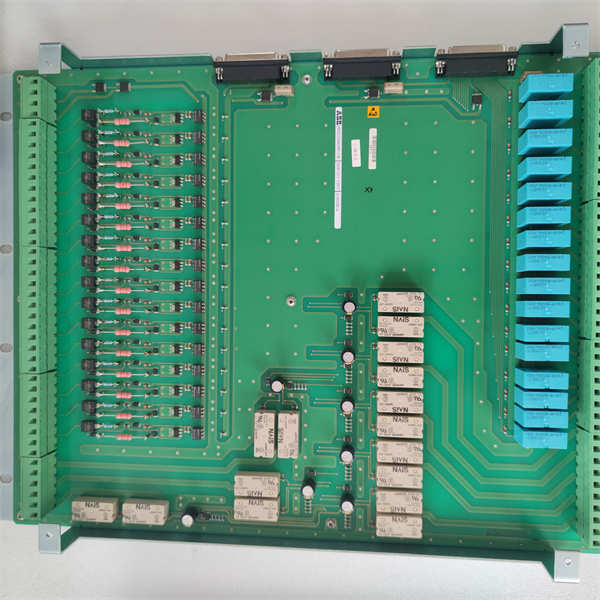

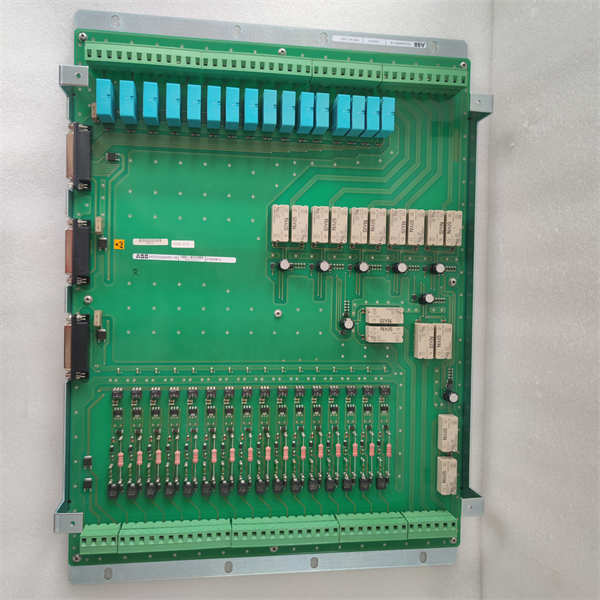

GMKP2800-32IBY

GMKP2800-32IBY

MKS RPS AX7695 is a high performance remote plasma source,which is widely used in semiconductor manufacturing,photovoltaics,display and other fields.The following is a comprehensive overview of its core product features and technical parameters:

I.Core parameters and performance

Basic parameters

-Frequency:13.56 MHz

-Power:2 kW

-Plasma density:>10^12 cm^-3

-Plasma uniformity:<5%

-Dimensions:600 mm×400 mm×300 mm(standard version)/399 mm×348 mm×308 mm(integrated version)

-Weight:20 kg(standard version)/38.6 kg(integrated version)

Gas handling capacity

-Ignition gas:100%O₂,Ar or 90%O₂/10%N₂(expandable to other gases)

-Process gas:supports O₂or O₂/N₂mixed gas flow up to 6.0 slm

II.Technical features

High density and uniformity

Using radio frequency(RF)and microwave technology,high-density,uniformly distributed plasma is generated,which is suitable for precision material processing.

Integrated design

The power supply,matching network,and plasma chamber are integrated into a compact unit,which is convenient for direct installation in the process chamber to reduce space occupation.

Flexibility and compatibility

Supports a variety of gas types and process parameter adjustments,suitable for different semiconductor manufacturing processes such as etching,deposition,and cleaning.

Reliability and maintenance

-Long-life design,suitable for harsh industrial environments;

-Modular structure,convenient maintenance,and reduced downtime.

III.Structure and working principle

Core components

-Power supply:Provide high-frequency energy to drive plasma generation;

-Matching network:Optimize energy transmission efficiency;

-Plasma chamber:Excite gas through electromagnetic field to form plasma,and transmit it to the target surface through the outlet.

Control and communication

Support RS-232,DeviceNet,Ethernet and other interfaces,compatible with MKS TOOLweb®and other control systems,to achieve remote monitoring and intelligent linkage.

IV.Application field

Semiconductor manufacturing

Wafer cleaning,photoresist removal,thin film deposition and other processes.

Photovoltaics and displays

Surface treatment such as glass coating and panel etching.

Other fields

Modification of biomedical devices,surface strengthening of aerospace materials,etc.