描述

一、产品定位与核心优势

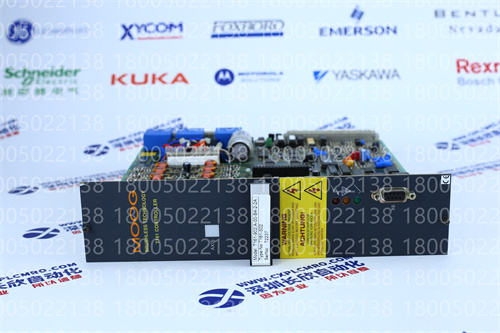

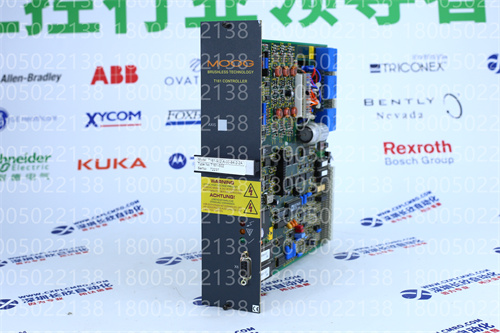

1.品牌与产品线归属

MOOG(穆格):

全球领先的运动控制与液压技术供应商,专注于航空航天、工业自动化、能源装备等领域的高精度控制解决方案。

T161-902A-00-B4-2-2A01是MOOG伺服阀系列中的一款高性能两级电液伺服阀,主要用于高动态响应、高精度的液压系统控制。

2.核心优势

高动态响应:

频率响应达100 Hz以上,可快速跟踪电信号变化,适用于振动控制、快速定位等场景。

高精度控制:

滞环误差≤1%,线性度误差≤3%,确保输出流量/压力与输入信号高度一致。

抗污染能力强:

采用MOOG专利的滤网设计,可耐受NAS 1638 7级污染度(ISO 4406 18/16/13),延长使用寿命。

兼容性强:

支持±10 VDC或±4 mA~±20 mA输入信号,可与PLC、运动控制器、数据采集系统无缝对接。

3.典型应用场景

航空航天:

飞行模拟器:控制液压作动筒,模拟飞机姿态变化。

火箭发动机测试:调节推进剂流量,确保燃烧稳定性。

工业自动化:

注塑机:控制液压系统压力与流量,优化注塑成型质量。

金属压铸:调节合模力与注射速度,减少产品缺陷。

能源装备:

风力发电机组:控制偏航与变桨系统,提升发电效率。

汽轮机调速:调节蒸汽阀门开度,维持机组转速稳定。

二、技术参数详解

1.基础规格

参数类别规格详情

型号MOOG T161-902A-00-B4-2-2A01

系列MOOG T Series(高性能伺服阀系列)

安装方式法兰安装(ISO 4401-03-02-0-94标准)或管式连接(G1/2螺纹)

阀体材质不锈钢(316L)或高强度合金钢(防腐蚀处理)

防护等级IP65(防尘、防喷水),适用于室内工业环境

重量约2.5 kg(含连接件)

2.性能参数

参数类别规格详情

额定流量161 L/min( 70 bar压降,100%阀口开度)

供油压力范围70 bar~210 bar(可定制更高压力型号)

输入信号±10 VDC(电压控制)或±4 mA~±20 mA(电流控制)

频率响应-3 dB带宽****:100 Hz(典型值)

阶跃响应时间:≤10 ms(10%~90%上升时间)

滞环误差≤1%FS(满量程)

线性度误差≤3%FS

温度范围工作温度:-20℃~+80℃

存储温度:-40℃~+100℃

3.电气与接口参数

参数类别规格详情

电源要求24 VDC(±10%),功耗≤50 W(典型值)

电气连接D-sub 15针接口(信号输入、反馈、电源)

可选:M12圆形连接器(工业现场总线兼容)

反馈信号内置位移传感器(LVDT),输出±10 VDC或4-20 mA信号(可配置)

通信协议模拟量控制(默认)

可选:CANopen、Profibus-DP、EtherCAT(需定制)

4.认证与标准

认证类型详情

安全认证CE认证(符合EU低电压指令2014/35/EU)

UL认证(可选,适用于北美市场)

环境标准RoHS 2.0(无铅化)

REACH(化学品注册)

行业认证NAMUR(过程自动化行业规范)

ISO 9001(质量管理体系)

三、功能特性解析

1.两级阀芯设计

先导级:

采用喷嘴挡板结构,将电信号转换为液压信号,实现高精度初始控制。

功率级:

滑阀结构,放大先导级信号,驱动主阀芯移动,输出大流量/高压液压油。

优势:

低功耗(先导级仅需微小电流),高效率(功率级直接驱动负载)。

2.动态压力补偿

内置压力补偿器:

自动调节阀口压降,确保流量输出与负载压力无关,提升系统稳定性。

应用场景:

负载变化频繁的系统(如注塑机合模缸),避免压力波动导致流量不稳定。

3.故障诊断与保护

自诊断功能:

监测输入信号、反馈信号、阀芯位置,通过LED指示灯或通信接口报警。

保护机制:

过压保护:当供油压力超过设定值时,自动关闭阀口。

过热保护:当阀体温度超过100℃时,触发降功率运行。

1.Product positioning and core advantages

1.Brand and product line ownership

MOOG:

A global leading supplier of motion control and hydraulic technology,focusing on high-precision control solutions in the fields of aerospace,industrial automation,energy equipment,etc.

T161-902A-00-B4-2-2A01 is a high-performance two-stage electro-hydraulic servo valve in the MOOG servo valve series,mainly used for high dynamic response and high-precision hydraulic system control.

2.Core advantages

High dynamic response:

The frequency response is above 100 Hz,which can quickly track the changes of electrical signals and is suitable for vibration control,rapid positioning and other scenarios.

High-precision control:

Hysteresis error≤1%,linearity error≤3%,ensuring that the output flow/pressure is highly consistent with the input signal.

Strong anti-pollution ability:

The filter design with MOOG patent can withstand NAS 1638 level 7 pollution(ISO 4406 18/16/13)and extend the service life.

Strong compatibility:

Supports±10 VDC or±4 mA~±20 mA input signals,and can be seamlessly connected with PLC,motion controller,and data acquisition system.

3.Typical application scenarios

Aerospace:

Flight simulator:Control hydraulic actuators to simulate aircraft attitude changes.

Rocket engine testing:Adjust propellant flow to ensure combustion stability.

Industrial automation:

Injection molding machine:Control hydraulic system pressure and flow to optimize injection molding quality.

Metal die casting:Adjust clamping force and injection speed to reduce product defects.

Energy equipment:

Wind turbine:Control yaw and pitch system to improve power generation efficiency.

Steam turbine speed regulation:Adjust steam valve opening to maintain stable unit speed.

2.Technical Parameters

1.Basic Specifications

Parameter Category Specification Details

Model MOOG T161-902A-00-B4-2-2A01

Series MOOG T Series(High-Performance Servo Valve Series)

Installation Flange Installation(ISO 4401-03-02-0-94 Standard)or Pipe Connection(G1/2 Thread)

Valve Body Material Stainless Steel(316L)or High-Strength Alloy Steel(Anti-Corrosion Treatment)

Protection Level IP65(Dustproof,Water-Proof),Suitable for Indoor Industrial Environments

Weight Approximately 2.5 kg(including connectors)

2.Performance Parameters

Parameter Category Specification Details

Rated Flow 161 L/min( 70 bar pressure drop,100%valve opening)

Oil Supply Pressure Range 70 bar~210 bar(Higher Pressure Models Can Be Customized)

Input Signal±10 VDC(Voltage Control)or±4 mA~±20 mA(current control)

Frequency response-3 dB bandwidth****:100 Hz(typical)

Step response time:≤10 ms(10%~90%rise time)

Hysteresis error≤1%FS(full scale)

Linearity error≤3%FS

Temperature range Operating temperature:-20℃~+80℃

Storage temperature:-40℃~+100℃

3.Electrical and interface parameters

Parameter category Specification details

Power supply requirements 24 VDC(±10%),power consumption≤50 W(typical)

Electrical connection D-sub 15-pin interface(signal input,feedback,power supply)

Optional:M12 circular connector(industrial fieldbus compatible)

Feedback signal Built-in displacement sensor(LVDT),output±10 VDC or 4-20 mA signal(configurable)

Communication protocol Analog control(default)

Optional:CANopen,Profibus-DP,EtherCAT(customized)

4.Certification and Standards

Certification Type Details

Safety Certification CE Certification(Compliant with EU Low Voltage Directive 2014/35/EU)

UL Certification(optional,for North American market)

Environmental Standards RoHS 2.0(lead-free)

REACH(chemical registration)

Industry Certification NAMUR(process automation industry specification)

ISO 9001(quality management system)

III.Functional Characteristics Analysis

1.Two-stage valve core design

Pilot stage:

Adopts nozzle baffle structure to convert electrical signal into hydraulic signal to achieve high-precision initial control.

Power stage:

Sliding valve structure,amplifies pilot stage signal,drives main valve core to move,and outputs large flow/high-pressure hydraulic oil.

Advantages:

Low power consumption(pilot stage only requires small current),high efficiency(power stage directly drives load).

2.Dynamic pressure compensation

Built-in pressure compensator:

Automatically adjusts valve port pressure drop to ensure that flow output is independent of load pressure and improve system stability.

Application scenarios:

Systems with frequent load changes(such as injection molding machine clamping cylinders)to avoid unstable flow caused by pressure fluctuations.

3.Fault diagnosis and protection

Self-diagnosis function:

Monitor input signals,feedback signals,valve core positions,and alarm through LED indicators or communication interfaces.

Protection mechanism:

Overpressure protection:When the oil supply pressure exceeds the set value,the valve port is automatically closed.

Overheat protection:When the valve body temperature exceeds 100℃,it triggers power reduction operation.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101